Interface detect detection method based on improved multi-reflection full focusing imaging algorithm

A technology for multiple reflection and defect detection, which is applied in measuring devices, analyzing solids using sound waves/ultrasonic waves/infrasonic waves, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve problems such as debonding strength weakening, and achieve defect feature enhancement , Improving the effect of accuracy and detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

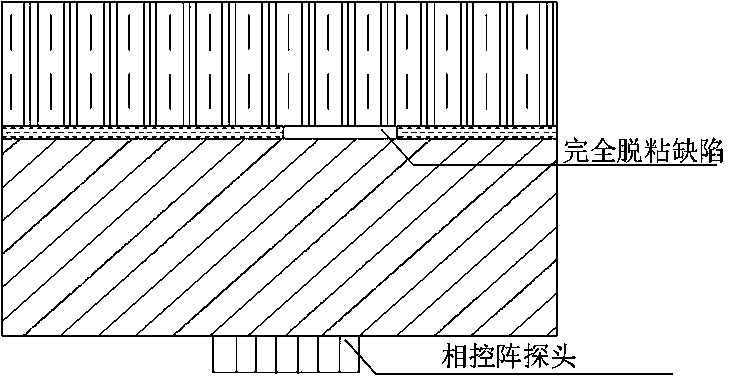

[0039] The invention provides a method for detecting interface defects based on an improved multi-reflection total-focus imaging algorithm, and the detection object is such as figure 1 Debonding defects of the bonded structure shown, including the following steps

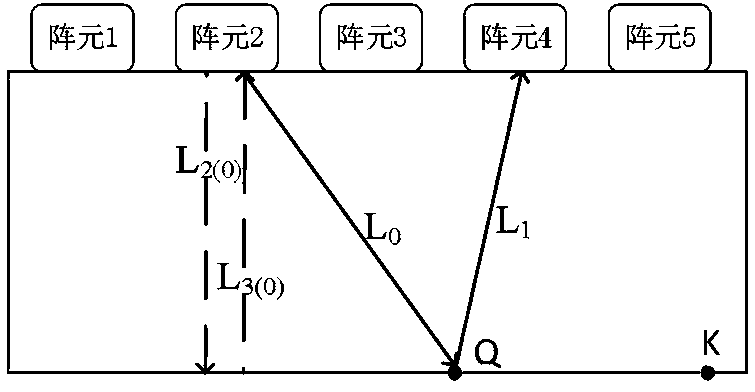

[0040] Step S1: According to the interface depth S and the time required for receiving P echoes, set the instrument parameters: assuming that the propagation speed of the sound wave in the workpiece is c, the maximum distance from the array element in the probe to the target imaging point (x, z) is u, Set the gate time T for the instrument to receive the echo as:

[0041]

[0042] Step S2: adopt full matrix capture technology to carry out echo capture of the workpiece to be measured;

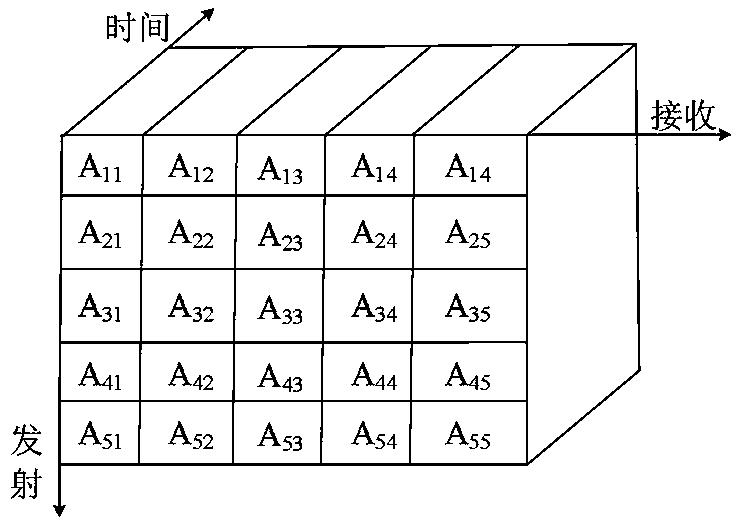

[0043] Step S21: Sequentially excite each element of the phased array probe to emit ultrasonic waves, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com