Composite component interface rapid imaging quantitative detection method based on full-matrix data

A quantitative detection method and composite component technology, which is applied in the field of rapid imaging quantitative detection of composite component interfaces based on full matrix data, can solve problems such as low detection accuracy, low imaging contrast, and impact on detection accuracy, so as to improve detection accuracy and improve Detection speed, effect of enhanced contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

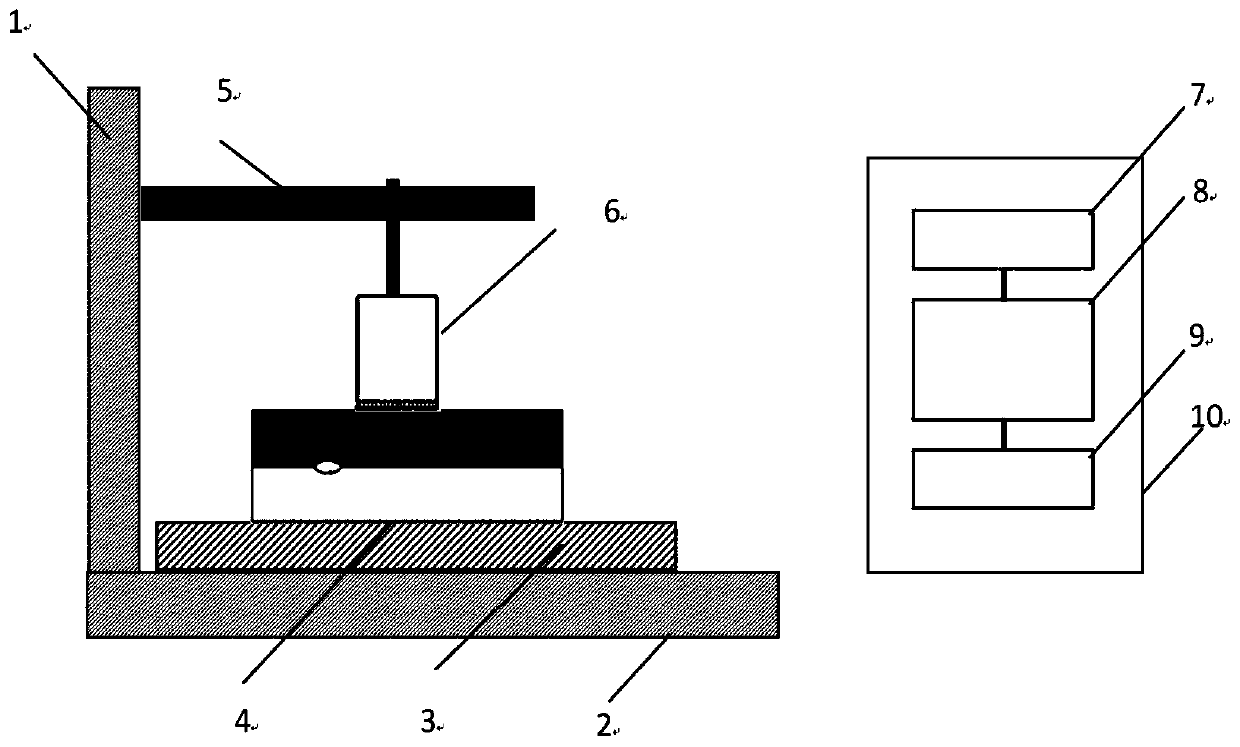

[0053] A method for rapid imaging and quantitative detection of composite component interfaces based on full matrix data, comprising the following steps:

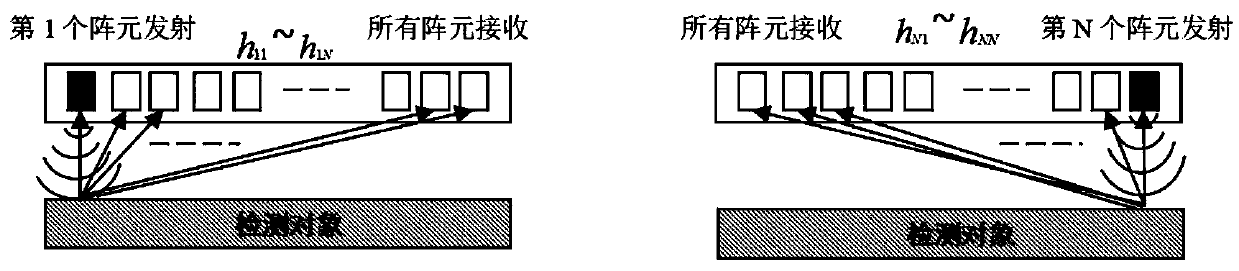

[0054] 1) if figure 2 As shown, full-matrix data acquisition: transmit ultrasonic waves, and the specific steps of collecting echo signals of composite components by means of full-matrix data acquisition are as follows: Assume that the phased array transducer that emits ultrasonic waves has a total of N array elements, and each time an array transducer is excited The element emits ultrasonic waves, and all the array elements in the array receive the reflected echo signal, and define the received echo signal as h 1j , and then the second one, the third one... the Nth array element emits ultrasonic waves, and obtains N*N groups of echo signals, which constitute N*N groups of full matrix data, where h ij Indicates that the i-th array element transmits ultrasonic waves and the j-th array element receives them, where i=1, 2......

Embodiment 2

[0068] 1) Full matrix data acquisition: such as figure 2 As shown, the specific steps of transmitting ultrasonic waves and adopting the full-matrix data acquisition method to collect echo signals of composite components are as follows: Assume that the phased array transducer that emits ultrasonic waves has a total of N array elements, and each time an array element is excited to emit ultrasonic waves, the array All array elements in receive their reflected echo signals, and define the received echo signal as h 1j , and then the second one, the third one... the Nth array element emits ultrasonic waves, and obtains N*N groups of echo signals, which constitute N*N groups of full matrix data, where h ij Indicates that the i-th array element transmits ultrasonic waves and the j-th array element receives them, where i=1, 2...N; j=1, 2...N. ;

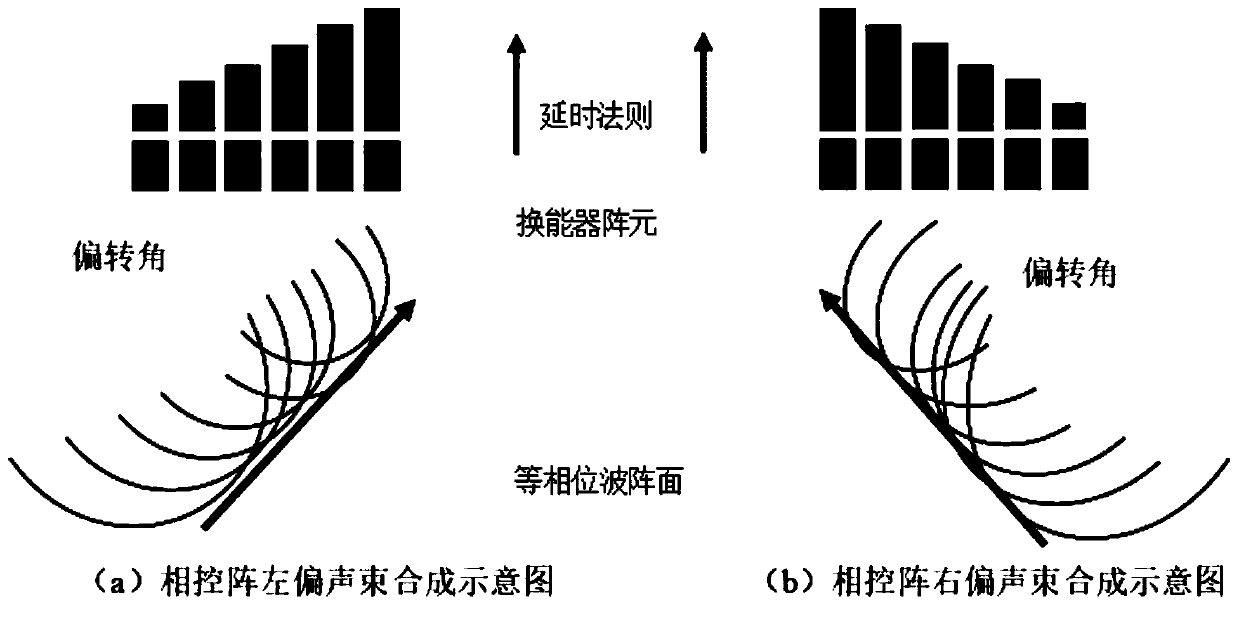

[0069] 2) Use the full-focus fast imaging algorithm based on full-matrix data to realize fast full-focus imaging of components. The specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com