Full-matrix data based ultrasonic all focusing and imaging system

An imaging system and a full-matrix technology, applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, detection of response signals, etc., can solve problems such as low precision and achieve rapid acquisition effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

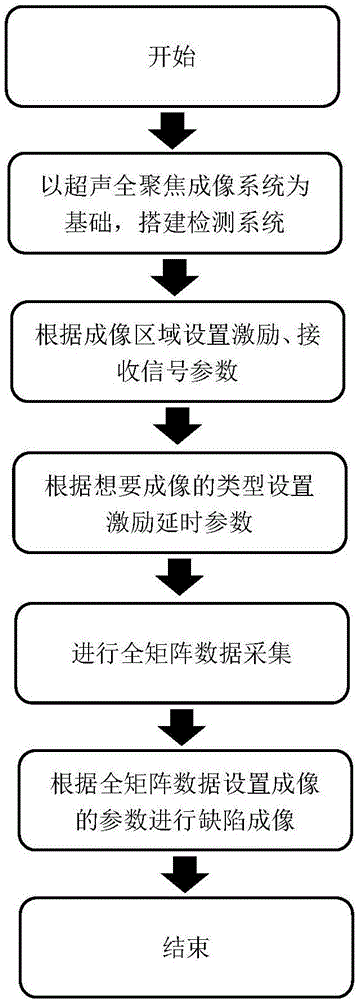

[0022] Step 1: Detection system construction and parameter setting;

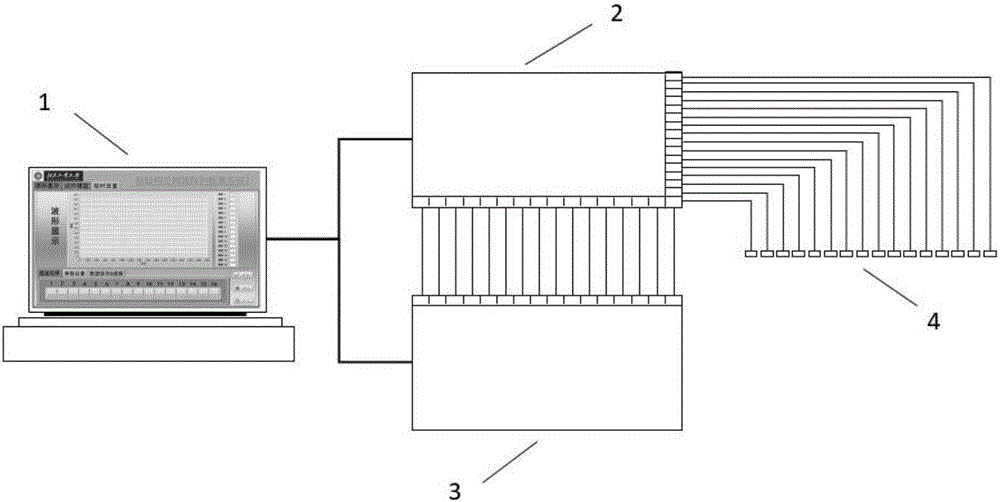

[0023] (1) According to figure 1 Based on the ultrasonic all-focus imaging system, a detection system is built; the system includes a computer 1, a multi-channel synchronous data acquisition card 2, a multi-channel ultrasonic excitation receiving phased array board 3, and an ultrasonic probe array 4. The computer 1 is connected to the multi-channel synchronous data acquisition card 2 through a signal line, the multi-channel synchronous data acquisition card 2 is connected to the multi-channel ultrasonic excitation receiving phased array board 3, and the multi-channel ultrasonic excitation receiving phased array board 3 is connected to the Ultrasonic probe arrays 4 are connected. The aluminum plate used in the detection experiment in this paper has a size of 1000mm×500mm×1mm. The ultrasonic probe array uses 8 piezoelectric array elements, the array element size is 6mm×6mm×0.5mm, the array element interval i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com