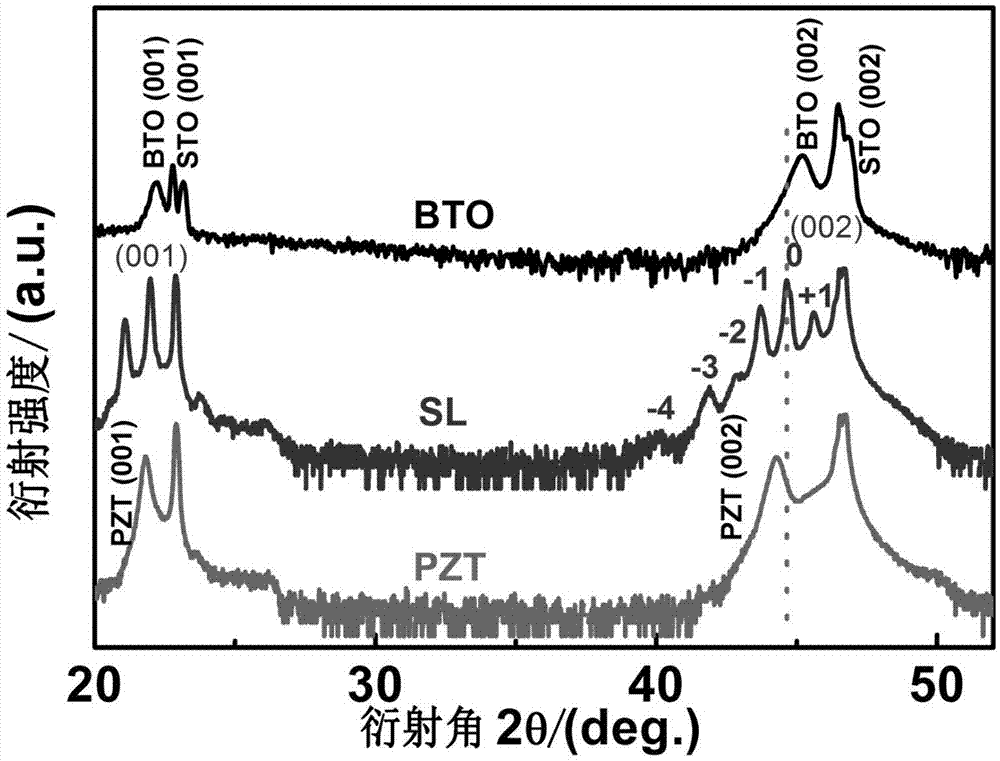

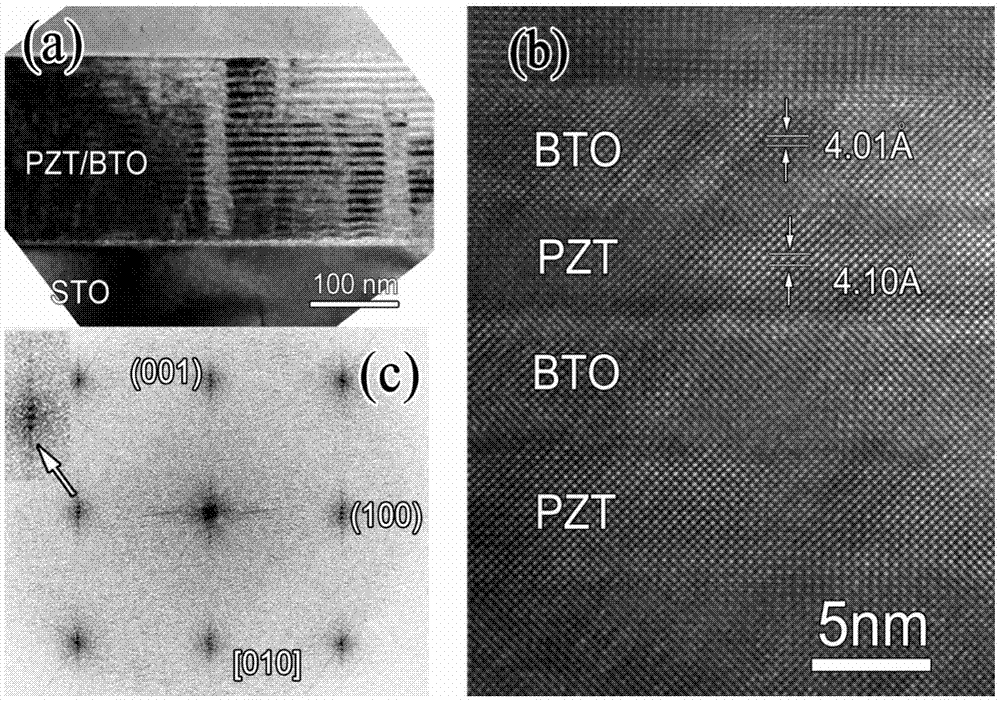

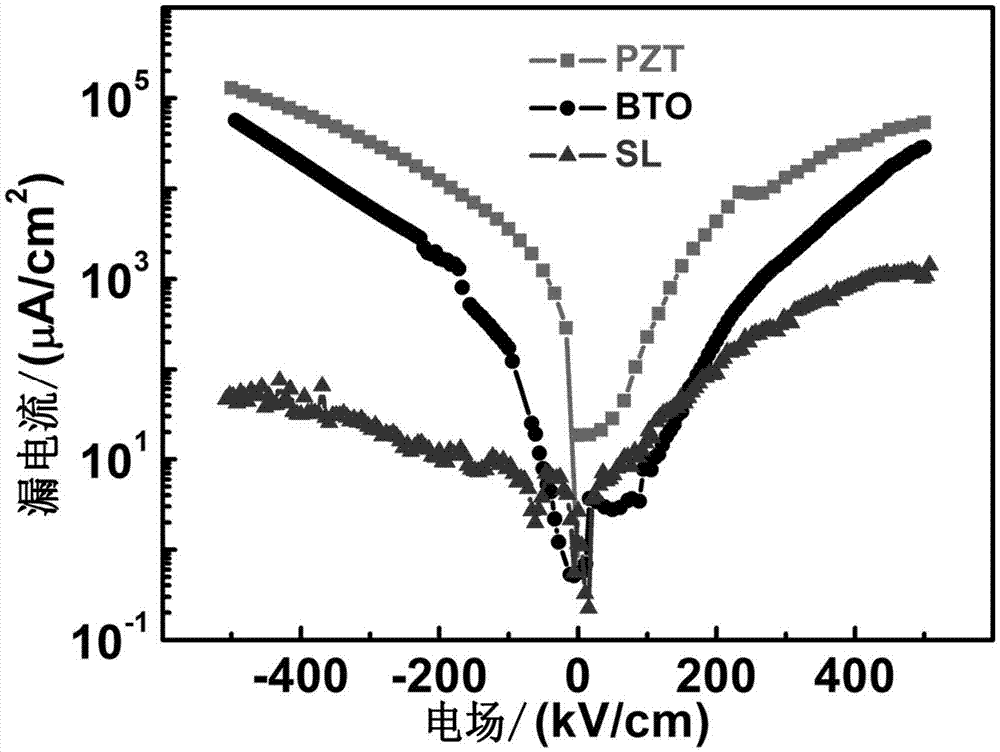

Lead zirconate titanate/barium titanate ferroelectric superlattice material, and preparation method thereof

A technology of lead zirconate titanate and superlattice, applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of non-compliance, high leakage current and loss, low ferroelectric polarization intensity, etc. Achieve the effect of symmetrical ferroelectric loop, low leakage current and high dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) 0.7% Nb-SrTiO 3 (001) The substrate is microwave-sonicated in acetone and alcohol for 20 minutes, then the substrate is heated to 750° C. in vacuum, and annealed for 60 minutes;

[0032] (2) Using pulsed laser deposition method, under the conditions of deposition temperature 750°C and oxygen pressure 40Pa, in 0.7% Nb-SrTiO 3 (001) Deposit lanthanum calcium manganese oxide 4nm on the substrate; Under the condition that the deposition temperature is changed to 650° C. and the oxygen pressure drops to 5Pa, 5 nm of lead zirconate titanate film is deposited on the lanthanum calcium manganese oxide;

[0033] (3) Under the conditions of maintaining the deposition temperature at 650°C and the oxygen pressure at 5 Pa, the laser bombarded the barium titanate target to make the deposition thickness 5nm. After 30 seconds, switched to the laser bombardment of the lead zirconate titanate target to make the deposition thickness 5nm. The periodic thickness of the superlattice mate...

Embodiment 2

[0038] (1) 0.7% Nb-SrTiO 3 (001) The substrate is microwave-sonicated in acetone and alcohol for 20 minutes, then the substrate is heated to 750° C. in vacuum, and annealed for 60 minutes;

[0039] (2) Using pulsed laser deposition method, under the conditions of deposition temperature 750°C and oxygen pressure 40Pa, in 0.7% Nb-SrTiO 3 (001) Deposit lanthanum calcium manganese oxide 4nm on the substrate; Under the condition that the deposition temperature is changed to 650° C. and the oxygen pressure drops to 5Pa, 5 nm of lead zirconate titanate film is deposited on the lanthanum calcium manganese oxide;

[0040] (3) Under the conditions of maintaining a deposition temperature of 650°C and an oxygen pressure of 5Pa, the laser bombarded the barium titanate target to make the deposition thickness 2.5nm. After 30 seconds, switched to the laser bombardment of the lead zirconate titanate target to make the deposition thickness 2.5nm. , the periodic thickness of the superlattice ma...

Embodiment 3

[0043] (1) 0.7% Nb-SrTiO 3 (001) The substrate is microwave-sonicated in acetone and alcohol for 20 minutes, then the substrate is heated to 750° C. in vacuum, and annealed for 60 minutes;

[0044] (2) Using pulsed laser deposition method, under the conditions of deposition temperature 750°C and oxygen pressure 40Pa, in 0.7% Nb-SrTiO 3 (001) Deposit lanthanum calcium manganese oxide 4nm on the substrate; Under the condition that the deposition temperature is changed to 650° C. and the oxygen pressure drops to 5Pa, 5 nm of lead zirconate titanate film is deposited on the lanthanum calcium manganese oxide;

[0045] (3) Under the conditions of maintaining the deposition temperature of 650°C and the oxygen pressure of 5Pa, the laser bombarded the barium titanate target to make the deposition thickness 36nm. After 30 seconds, switched to the laser bombardment of the lead zirconate titanate target to make the deposition thickness 36nm. The periodic thickness of the superlattice mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com