Method for measuring ferroelectric hysteresis loop of leakage ferroelectric film

A technology of ferroelectric thin film and hysteresis loop, applied in the direction of measuring current/voltage, measuring electrical variables, measuring devices, etc., can solve the problems of deepening the difficulty of thin film electrical measurement, unclear understanding of people, and increase of quantum tunneling current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

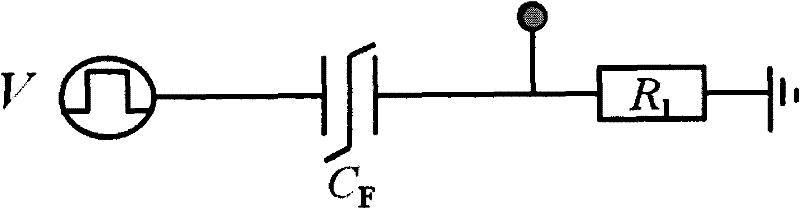

[0026] The pulse signals required for the test are all edited by Agilent 81150A arbitrary waveform signal generator, the current is recorded by LCWR6200A oscilloscope, and the internal resistance of the system is 50 ohms.

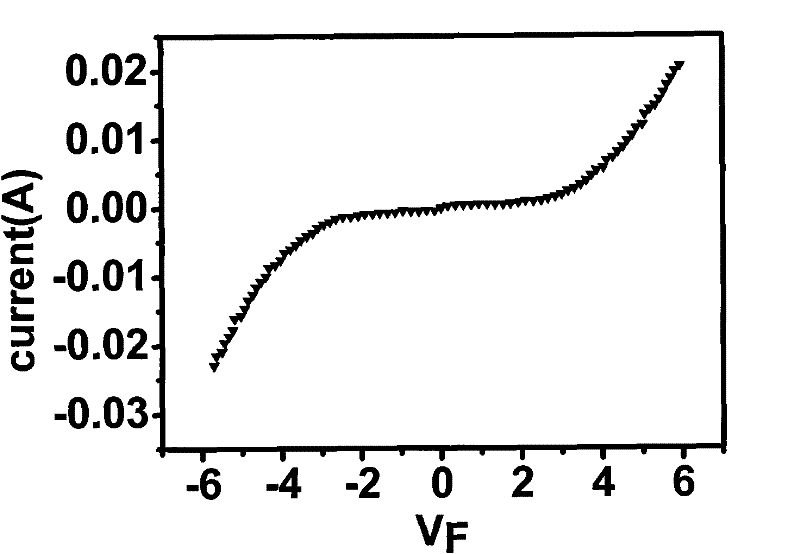

[0027] Measure a simulated leakage ferroelectric thin film system consisting of a standard ferroelectric capacitor and resistor in parallel.

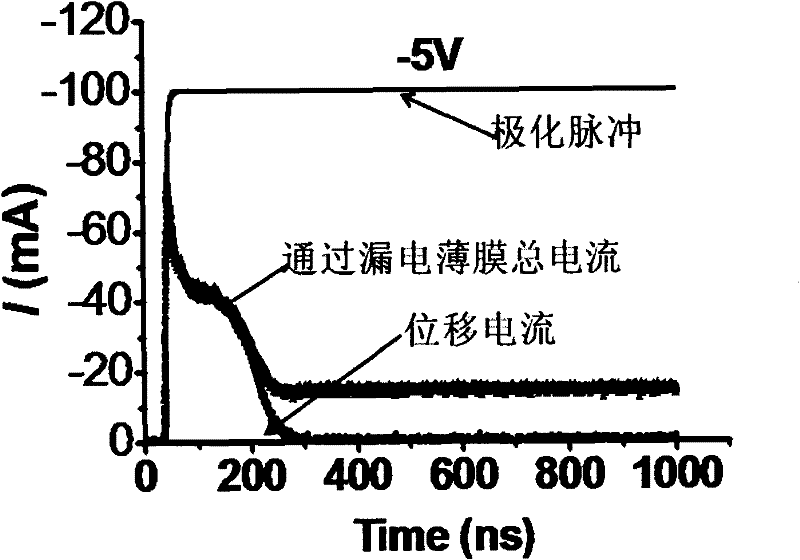

[0028] (1) Use a pulse generator to first generate a pulse with a sufficient width so that the reversible electric domain in the measured leakage ferroelectric film is completely reversed under the applied voltage.

[0029] (2) After the current is stable, measure the current passing through the ferroelectric film with the same polarity as the leakage current. Since the polarization direction of the ferroelectric domain is consistent with the direction of the external electric field at this time, the measurement process is carried out after the capacitor is fully charged, and the measured current only includes the lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com