Xsrtio3-(1-x) cofe2o4 composite material and preparation method thereof

A composite material and solution technology, which is applied in the field of composite multiferroic material preparation, can solve problems such as insufficient compactness, failure to reach the furnace, and existence of samples, so as to reduce the influence of external factors, avoid external factors, and improve ferroelectric properties. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] When x=0.5, the preparation of SrTiO with a composite ratio of strontium titanate and cobalt ferrite at 1:1 3 -CoFe 2 o 4 Composite powder. The preparation process is as follows:

[0024] (1) Dissolve 0.04mol of strontium nitrate and 0.04mol of citric acid in deionized water, and fully stir for 10min to form a citrate solution;

[0025] (2) First add 46.3ml of absolute ethanol to the beaker, then pour 4.63ml of glacial acetic acid, stir slightly, and finally add 13.89ml of butyl titanate to form a butyl titanate alcohol solution, and the citrate obtained in step (1) The solution and the butyl titanate alcohol solution were fully mixed and stirred for 30 minutes until light yellow and transparent, and the strontium titanate solution was obtained;

[0026] (3) To prepare cobalt ferrite solution, dissolve 0.04mol cobalt nitrate and 0.08mol ferric nitrate in deionized water, then add 0.08mol citric acid, and fully stir for 10min to obtain brown-red cobalt ferrite soluti...

Embodiment 2

[0032] The method is carried out as in Example 1, but the difference is that the sintering temperature is 900°C.

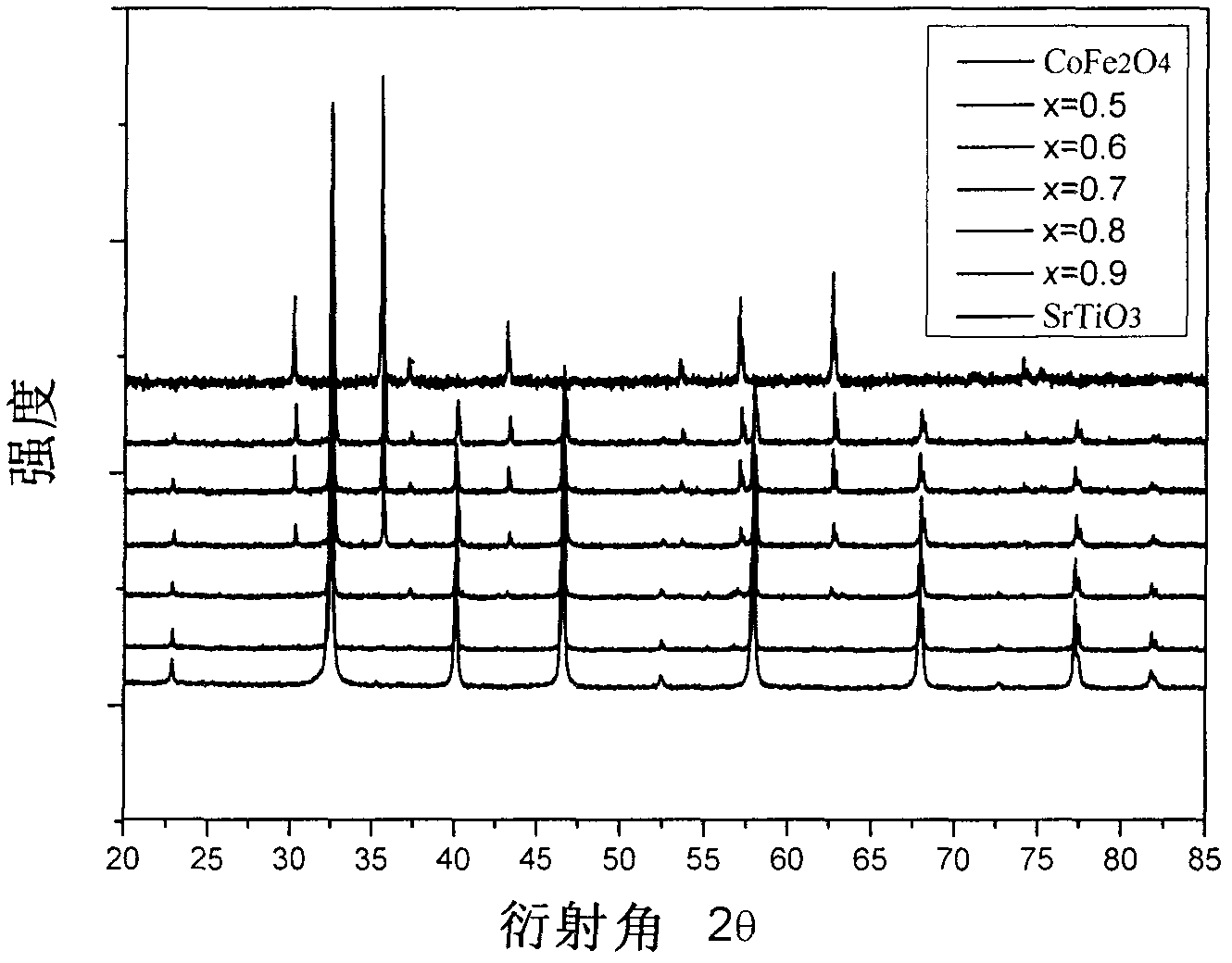

[0033] X-ray analysis shows that the composite ceramics initially form the diffraction peaks of strontium titanate and cobalt ferrite in the cubic phase, but there are Fe 2 o 3 Impurities, this is because the sintering temperature is not enough.

Embodiment 3

[0035] When x=0.9, the preparation of 0.9SrTiO with a composite ratio of strontium titanate and cobalt ferrite of 9:1 3 -0.1CoFe 2 o 4 Composite powder. The process is as follows:

[0036] (1) Dissolve 0.036mol of strontium nitrate and 0.036mol of citric acid in deionized water, and fully stir for 10min to form a citrate solution;

[0037] (2) First add 41.6ml of absolute ethanol, then pour 4.16ml of glacial acetic acid, stir slightly, and finally add 12.50ml of butyl titanate to form a butyl titanate alcohol solution, and mix the citrate solution obtained in step (1) with titanium The butyl ester alcohol solution was fully mixed and stirred for 30 minutes until it was light yellow and transparent, and the strontium titanate solution was obtained;

[0038] (3) To prepare a cobalt ferrite solution, dissolve 0.004mol cobalt nitrate and 0.008mol ferric nitrate in deionized water, then add 0.008mol citric acid, and stir for 10 minutes to obtain a brown-red cobalt ferrite solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com