Cement-based porous filter material prepared from waste circuit board non-metal powder and preparation method thereof

A technology for discarded circuit boards and non-metallic powders, applied in the direction of filtration separation, separation methods, ceramic material production, etc., can solve the problems of limited application and high production costs, and achieve the effects of reduced production costs, high compressive strength, and small pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

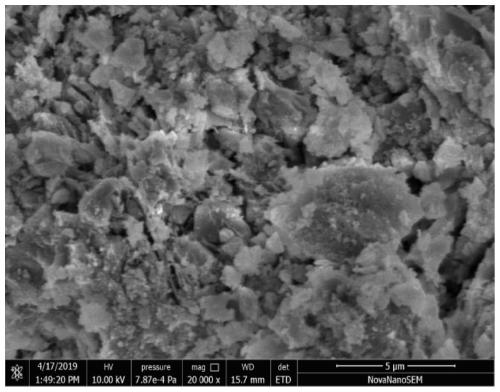

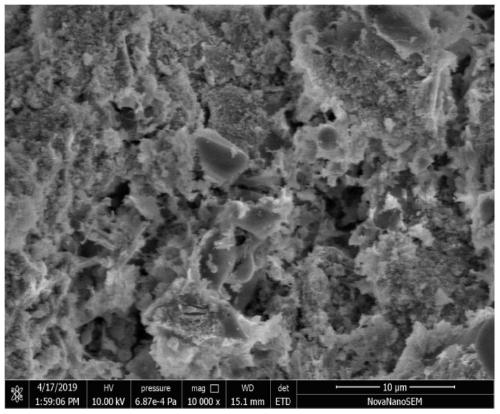

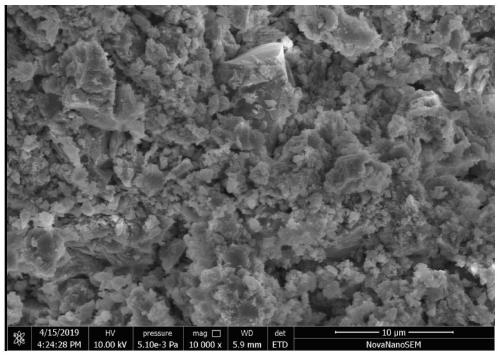

Image

Examples

preparation example Construction

[0038] The preparation method of the cement-based porous filter material prepared by waste circuit board non-metallic powder comprises the following steps:

[0039]1) Weigh waste circuit board non-metallic powder, aluminate cement, and desulfurized gypsum according to the formula, and mix them in a mixer for 10-20 minutes to obtain a dry material mixture;

[0040] 2) Add tap water (or clean river water) accounting for 12 to 15% of the weight of the dry mixture to the dry mixture prepared in step 1), and then start the mixer to mix for 5 to 10 minutes to obtain a wet mixture.

[0041] 3) Press the wet material mixture prepared in step 2) into a billet, the molding pressure is 10-20MPa, and the holding time is 50-70s;

[0042] 4) Put the blank formed in step 3) into a curing box with a temperature of 25±2°C and a humidity of 70-85% for 48±2 hours, and then move it into a curing box with a temperature of 60±2°C and a humidity of ≥90% 72±3 h in the curing box.

[0043] 5) Put th...

Embodiment 1

[0047] Proportion: 75 parts of waste circuit board non-metallic powder, 24 parts of aluminate cement, and 1 part of desulfurized gypsum.

[0048] Preparation:

[0049] (1) Weigh waste circuit board non-metallic powder, aluminate cement and desulfurized gypsum according to the formula, and mix them in a mixer for 10-20 minutes to obtain a dry material mixture;

[0050] (2) Add tap water (or clean river water) accounting for 12-15% of the weight of the dry material mixture to the dry material mixture prepared in step (1), then start the mixer and mix for 5-10 minutes to obtain a wet material mixture.

[0051] (3) Press the wet material mixture prepared in step (2) into a billet, the molding pressure is 10MPa, and the holding time is 50-70s;

[0052] (4) Put the green body pressed and formed in step (3) into a curing box with a temperature of 25±2°C and a humidity of 70-85% for 48±2 hours, and then move it into a curing box with a temperature of 60±2°C and a humidity of ≥90 72±...

Embodiment 2

[0056] Proportion: 77 parts of waste circuit board non-metallic powder, 22 parts of aluminate cement, and 1 part of desulfurized gypsum.

[0057] Preparation:

[0058] (1) Weigh waste circuit board non-metallic powder, aluminate cement and desulfurized gypsum according to the formula, and mix them in a mixer for 10-20 minutes to obtain a dry material mixture;

[0059] (2) Add tap water (or clean river water) accounting for 12-15% of the weight of the dry material mixture to the dry material mixture prepared in step (1), then start the mixer and mix for 5-10 minutes to obtain a wet material mixture.

[0060] (3) Press the wet material mixture prepared in step (2) into a billet, the molding pressure is 10MPa, and the holding time is 50-70s;

[0061] (4) Put the green body pressed and formed in step (3) into a curing box with a temperature of 25±2°C and a humidity of 70-85% for 48±2 hours, and then move it into a curing box with a temperature of 60±2°C and a humidity of ≥90 72±...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com