Calcination process and device of building gypsum powder

A technology of building gypsum powder and calcination process, which is applied in the field of gypsum powder production, can solve the problems of unbalanced heat distribution, unstable calcination temperature, and large flue gas emission in a calciner, so as to improve heat utilization efficiency, reduce temperature and exhaust gas. The effect of low emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

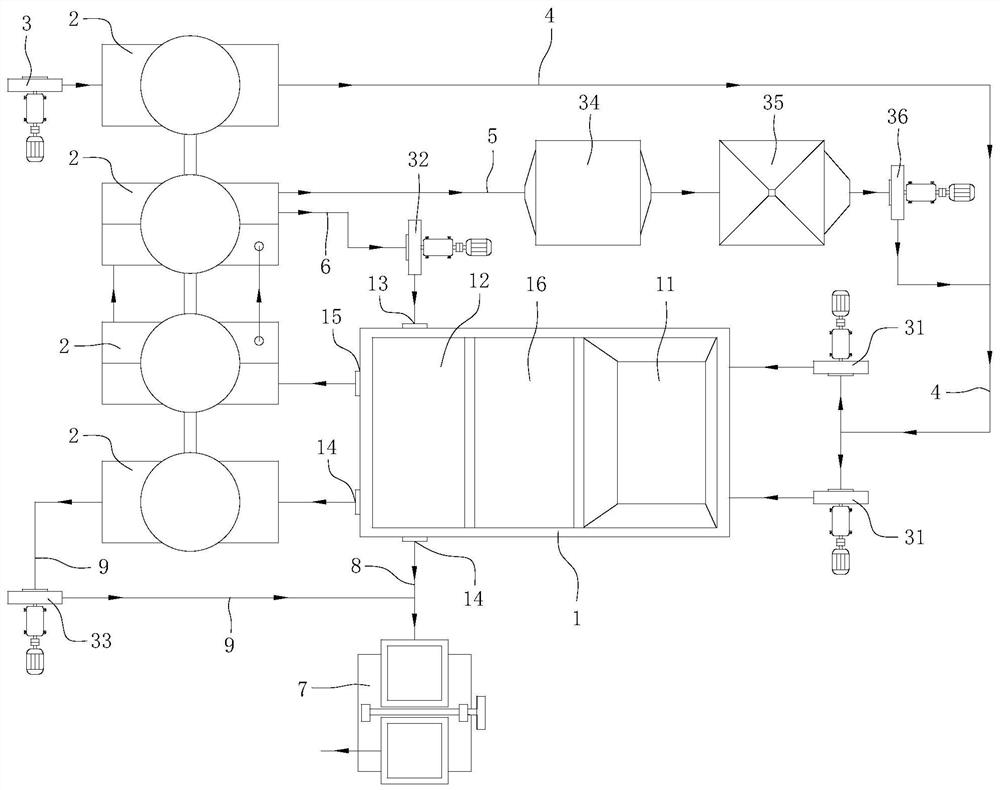

[0064] High temperature flue gas S 0 temperature T 0 =900℃; high temperature flue gas S 1 temperature T 1 =750℃; high temperature flue gas S 2 temperature T 2 =650℃; low temperature flue gas S 1 'Temperature T 1 '=170℃; low temperature flue gas S 2 'Temperature T 2 '=180°C; normal temperature air S 3 temperature T 3 =20℃; hot air S 3 'Temperature T 3 '=60℃; mixed gas S 4 temperature T 4 =100℃; mixed gas S 5 temperature T 5 =550°C; the calcining temperature in the first fluidized calciner 2 is 135°C, the calcined temperature in the second fluidized calciner 2 is 145°C, and the calcined temperature in the third fluidized calciner 2 is 150°C. The cooling temperature in the four fluidized calciners 2 was 110°C.

[0065] By adopting the calcination process of the present invention, under the above process conditions, not only qualified building gypsum powder can be produced, but also compared with the existing process, the calcination process of the present inventio...

Embodiment 2

[0067] High temperature flue gas S 0 temperature T 0 =950℃; high temperature flue gas S 1 temperature T 1 =780℃; high temperature flue gas S 2 temperature T 2 =690℃; low temperature flue gas S 1 'Temperature T 1 '=175℃; low temperature flue gas S 2 'Temperature T 2 '=185°C; normal temperature air S 3 temperature T 3 =25℃; hot air S 3 'Temperature T 3 '=65℃; mixed gas S 4 temperature T 4 =105℃; mixed gas S 5 temperature T 5 =580°C; the calcining temperature in the first fluidized calciner 2 is 130°C, the calcined temperature in the second fluidized calciner 2 is 140°C, and the calcined temperature in the third fluidized calciner 2 is 155°C. The cooling temperature in the four fluidized calciners 2 was 112°C.

[0068] By adopting the calcination process of the present invention, under the above process conditions, not only qualified building gypsum powder can be produced, but also compared with the existing process, the calcination process of the present inventio...

Embodiment 3

[0070] High temperature flue gas S 0 temperature T 0 =850℃; high temperature flue gas S 1 temperature T 1 =730℃; high temperature flue gas S 2 temperature T 2 =620℃; low temperature flue gas S 1 'Temperature T 1 '=165℃; low temperature flue gas S 2 'Temperature T 2 '=175°C; normal temperature air S 3 temperature T 3 =15°C; hot air S 3 'Temperature T 3 '=55℃; mixed gas S 4 temperature T 4 =92℃; mixed gas S 5 temperature T 5 =520 DEG C; the calcining temperature in the first fluidized calciner 2 is 135 DEG C, the calcined temperature in the second fluidized calciner 2 is 145 DEG C, and the calcined temperature in the third fluidized calciner 2 is 150 DEG C. The cooling temperature in the four fluidized calciners 2 was 108°C.

[0071] By adopting the calcination process of the present invention, under the above process conditions, not only qualified building gypsum powder can be produced, but also compared with the existing process, the calcination process of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com