Preparation method of high-dielectric PI/PVDF composite film

A composite film and high dielectric technology, applied in the field of nanocomposite film preparation, can solve the problems of high temperature, low breakdown field strength of polymer composite film, increased energy consumption, etc., to achieve energy density improvement, avoid energy consumption, high The effect of breakdown field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

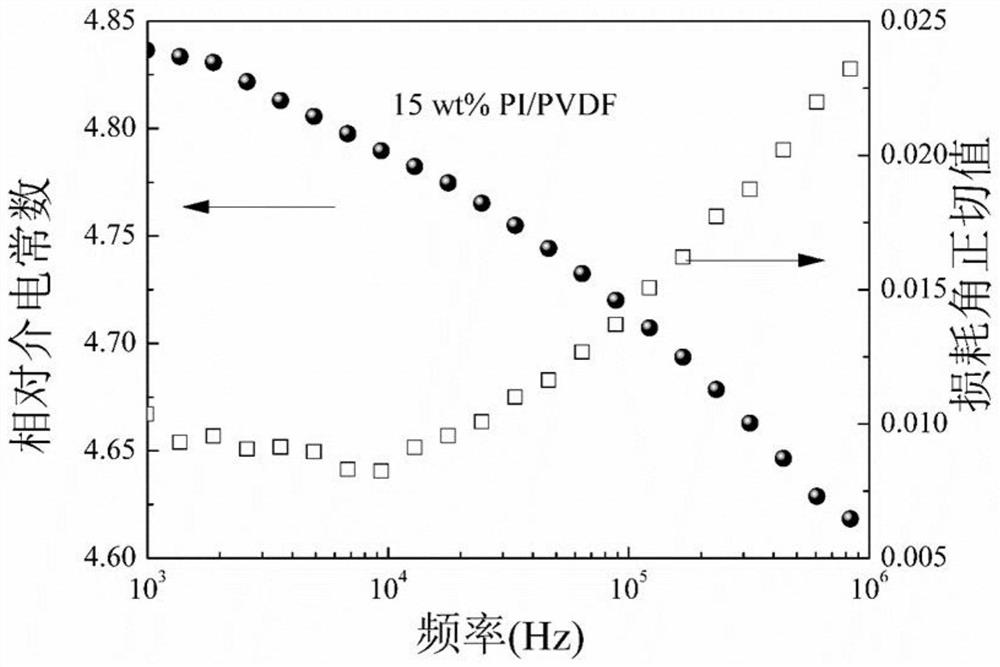

Embodiment 1

[0042] Embodiment 1: PI / PVDF composite film 1, the concrete operation steps are as follows:

[0043] 1) Disperse 4.00 grams of 4,4'-diaminodiphenyl ether in 50 milliliters of N,N'-dimethylacetamide, then divide 4.36 grams of pyromellitic dianhydride into 8 equal parts, Add in batches, and the time interval of each addition is at least 10 minutes to obtain product 1;

[0044] 2) At room temperature, 1.35 grams of PVDF was dissolved in 12 milliliters of N,N'-dimethylacetamide, and the product 2 with a solid content of 10.67 percent was obtained after processing under stirring conditions;

[0045] 3) at room temperature, the product 2 is divided into 5 equal parts, and after being added to the product 1 in batches, stirring is carried out, so that the product 2 and the product 1 are evenly mixed, and the interval for adding each batch is not less than 10 minutes, and then obtain product 3;

[0046] 4) The product 3 is processed into a film with a thickness of 400-500 microns by...

Embodiment 2

[0049] Embodiment 2: PI / PVDF composite film 2, the concrete operation steps are as follows:

[0050] 1) Disperse 4.00 grams of 4,4'-diaminodiphenyl ether in 50 milliliters of N,N'-dimethylacetamide, then divide 4.36 grams of pyromellitic dianhydride into 8 equal parts, Add in batches, and the time interval of each addition is at least 10 minutes to obtain product 1;

[0051] 2) At room temperature, 2.55 grams of PVDF was dissolved in 11 milliliters of N,N'-dimethylacetamide, and the product 2 with a solid content of 19.76 percent was obtained after processing under stirring conditions;

[0052] 3) at room temperature, the product 2 is divided into 5 equal parts, and after being added to the product 1 in batches, stirring is carried out, so that the product 2 and the product 1 are evenly mixed, and the interval for adding each batch is not less than 10 minutes, and then obtain product 3;

[0053] 4) The product 3 is processed into a film with a thickness of 400-500 microns by...

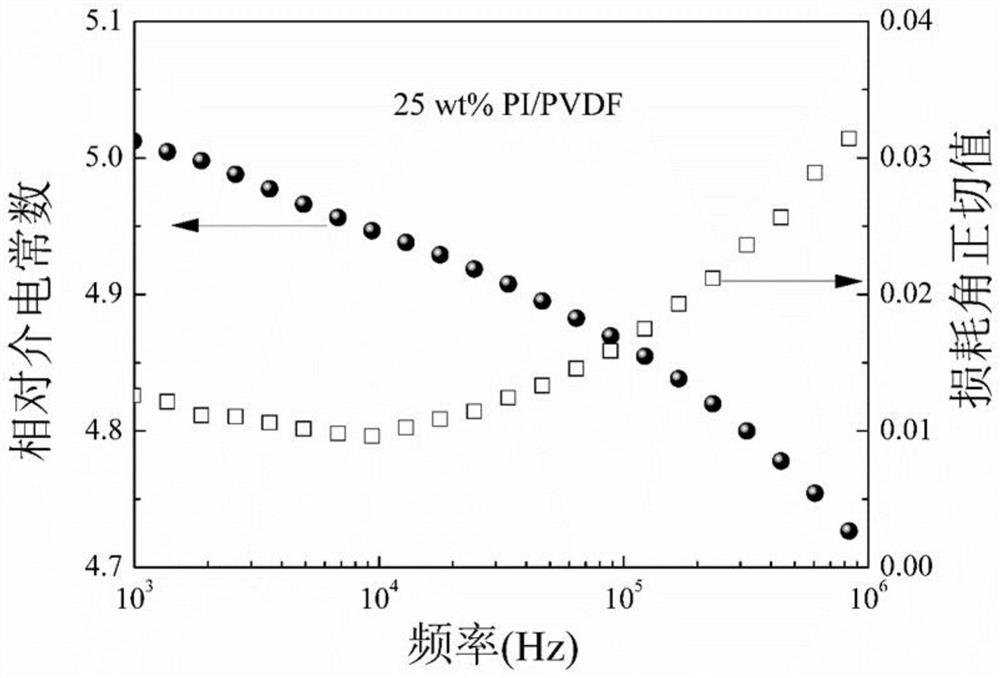

Embodiment 3

[0055] Embodiment 3: PI / PVDF composite film 3, concrete operation steps are as follows:

[0056] 1) Disperse 4.00 grams of 4,4'-diaminodiphenyl ether in 50 milliliters of N,N'-dimethylacetamide, then divide 4.36 grams of pyromellitic dianhydride into 8 equal parts, Add in batches, and the time interval of each addition is at least 10 minutes to obtain product 1;

[0057] 2) At room temperature, 3.94 grams of PVDF was dissolved in 23 milliliters of N,N'-dimethylacetamide, and the product 2 with a solid content of 15.40 percent was obtained after processing under stirring conditions;

[0058] 3) at room temperature, the product 2 is divided into 5 equal parts, and after being added to the product 1 in batches, stirring is carried out, so that the product 2 and the product 1 are evenly mixed, and the interval for adding each batch is not less than 10 minutes, and then obtain product 3;

[0059] 4) The product 3 is processed into a film with a thickness of 400-500 microns by the...

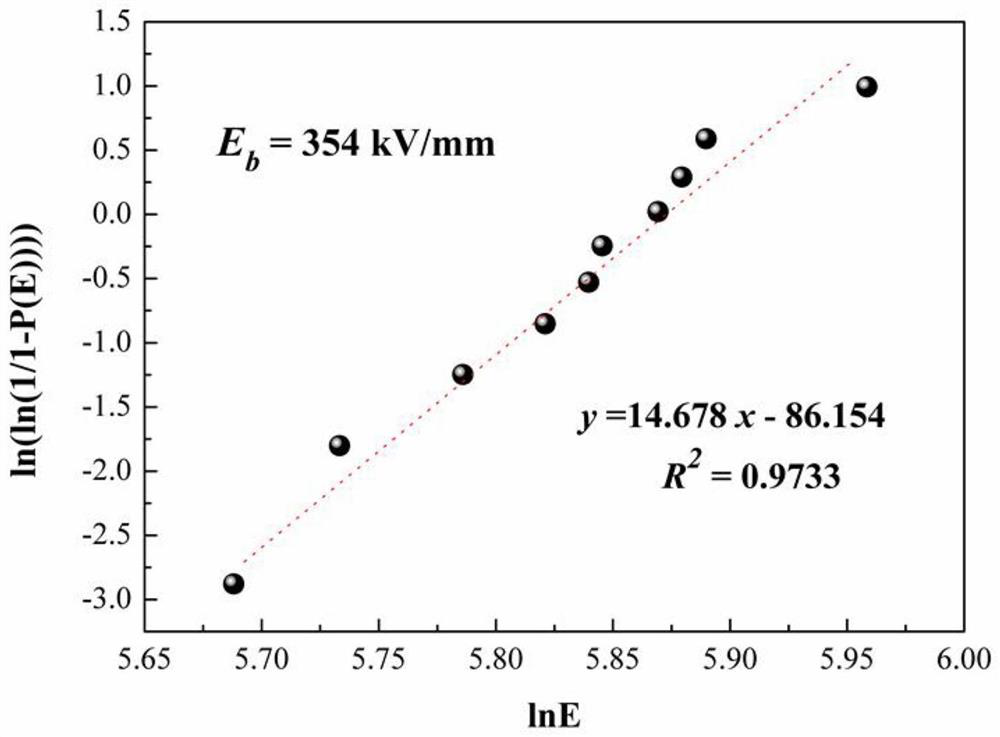

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breakdown field strength | aaaaa | aaaaa |

| Breakdown field strength | aaaaa | aaaaa |

| Breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com