High-breakdown ferroelectric ceramic and preparation method thereof

A ferroelectric ceramic, high breakdown technology, applied in the field of Na1-2xMgxNbO3 ferroelectric ceramic material and its preparation, can solve the problems of low breakdown field strength, hindering in-depth research on physical properties, and non-dense ceramics, etc. The effect of penetration field strength, low material cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

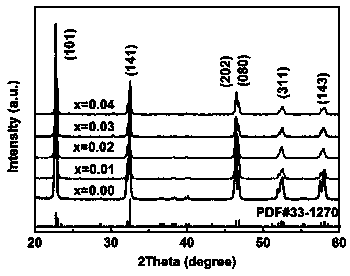

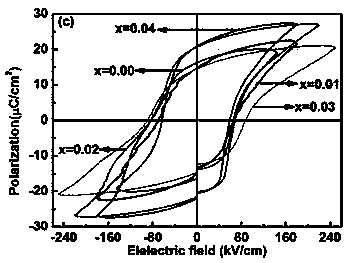

[0026] A high breakdown ferroelectric Na 1-2x Mg x NbO 3 A method for preparing a ceramic material, comprising the steps of:

[0027] Step 1: Preparation of pure phase NaNbO 3 spare. Weigh Na according to the molar ratio of 1:1 2 CO 3 and Nb 2 o 5 Mix to form mixture A; Na 2 CO 3 , Nb 2 o 5 The purity is above 99.0%.

[0028] Step 2: Take mixture A, zirconium balls and deionized water, mix them according to the mass ratio of 1:5:(0.8~1), 1:5:(1~1.2), and use planetary ball mill for 18~24h, Then dry at 85~100°C for 20~24h and briquette, then place it in a box furnace at 820~840°C for 3~4 hours to form NaNbO 3 Powder, spare;

[0029] Step 3: According to the chemical formula Na 1-2x Mg x NbO 3 , x =0~0.2, take NaNbO 3 Mix the powder and MgO powder evenly to form a full batch, and mix the full batch with zirconia balls and deionized water according to the mass ratio 1:(4.8~5.2):(0.8~1.2), then ball mill for 18~24h, bake Dry to obtain dried material;

[0030] ...

Embodiment 1

[0035] The preparation method of the high breakdown sodium niobate ferroelectric ceramics of the present invention, its formula is Na 1-2x Mg x NbO 3 ,in x =0.00.

[0036] Step 1: Preparation of pure phase NaNbO 3 Backup according to the molar ratio of 1:1 to take Na 2 CO 3 and Nb 2 o 5 Mix to form mixture A; Na 2 CO 3 , Nb 2 o 5 The purity is above 99.0%.

[0037] Step 2: Take the mixture A, zirconium balls and deionized water, mix them according to the mass ratio of 1:5:1, use a planetary ball mill for 24 hours, and then dry them at 80°C for 24 hours and briquette them. In a box furnace at 820°C for 4 hours to form NaNbO 3 Powder, spare;

[0038] Step 3: Take NaNbO 3 The powder is mixed with zirconia balls and deionized water according to the mass ratio of 1:5:1, then ball milled for 24 hours and dried to obtain the dried material;

[0039] Step 4: Grinding the dried material through a 120-mesh sieve to form a sieved material;

[0040] Step 5: The sieved mater...

Embodiment 2

[0043] The preparation method of the high breakdown sodium niobate ferroelectric ceramics of the present invention, its formula is Na 1-2x Mg x NbO 3 ,in x =0.01.

[0044] Step 1: Preparation of pure phase NaNbO 3 Backup according to the molar ratio of 1:1 to take Na 2 CO 3 and Nb 2 o 5 Mix to form mixture A; Na 2 CO 3 , Nb 2 o 5 The purity is above 99.0%.

[0045] Step 2: Take the mixture A, zirconium balls and deionized water, mix them according to the mass ratio of 1:5:1, use a planetary ball mill for 24 hours, and then dry them at 80°C for 24 hours and briquette them. In a box furnace at 820°C for 4 hours to form NaNbO 3 Powder, spare;

[0046] Step 3: According to the chemical formula Na 1-2x Mg x NbO 3 , x =0.01, take MgO powder and NaNbO 3 The powder is mixed evenly to form a full batch, and the full batch is mixed with zirconia balls and deionized water according to the mass ratio of 1:5:1, and then ball milled for 24 hours and dried to obtain a drie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com