Pulse-direct current alternate mixed anodizing method for anode foil for aluminum electrolytic capacitor

A technology of aluminum electrolytic capacitors and mixed anodes, applied in anodizing, electrolytic coatings, surface reaction electrolytic coatings, etc., to achieve the effects of increasing service life, increasing specific capacity, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

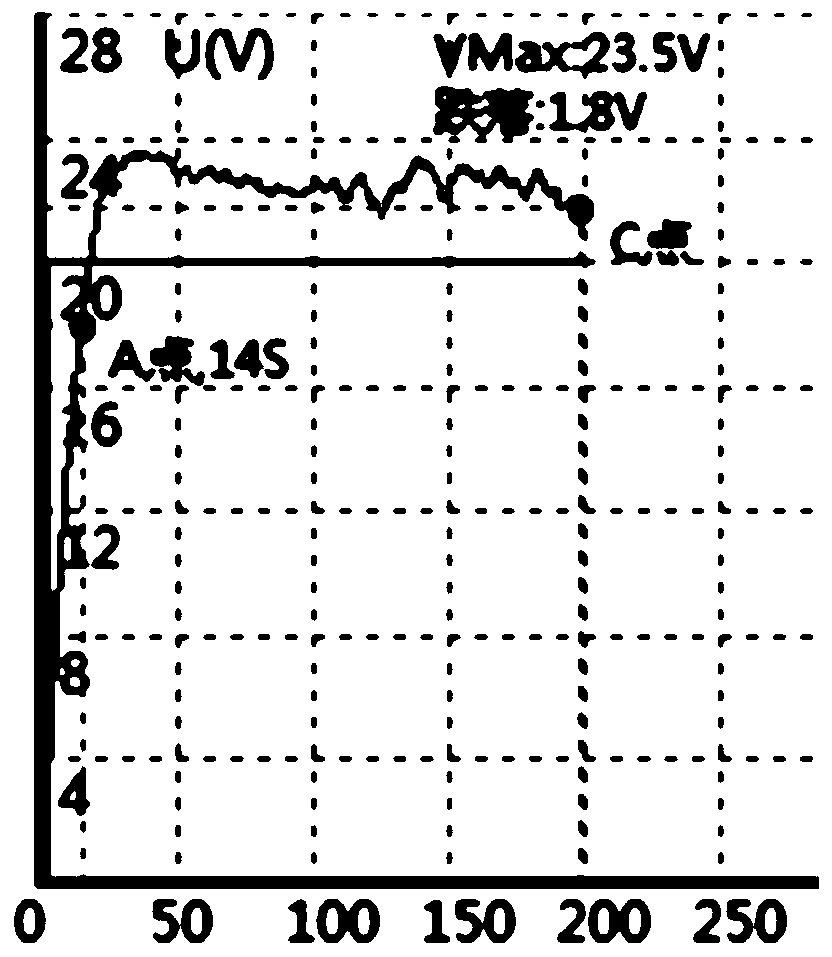

Image

Examples

Embodiment 1

[0031] Connect two pieces of corroded aluminum foil to the positive and negative output terminals of the pulse power supply respectively, immerse in 10% ammonium adipate and 0.04% oxalic acid solution at 85°C, at 10V, 100mA·cm -2 , Continue to oxidize under the condition of 0.5Hz. After the applied voltage rises to 10V, the constant voltage value lasts for 3 minutes. Then the aluminum foil was heat-treated in an air atmosphere at 600°C for 2 minutes, and then heated at 10V, 1mA·cm -2 Under the conditions of DC anodizing, it was formed for 2 minutes.

[0032] Through the test, the specific capacity of the DC sample is increased by 1.1%, the leakage current is reduced by 2.8%, the power consumption is reduced by 11.1%, and the production efficiency is increased by 60%; the specific capacity of the pulse sample is increased by 5% and the leakage current is reduced under the same withstand voltage 46.1%, power consumption is reduced by 9.8%, and production efficiency is increase...

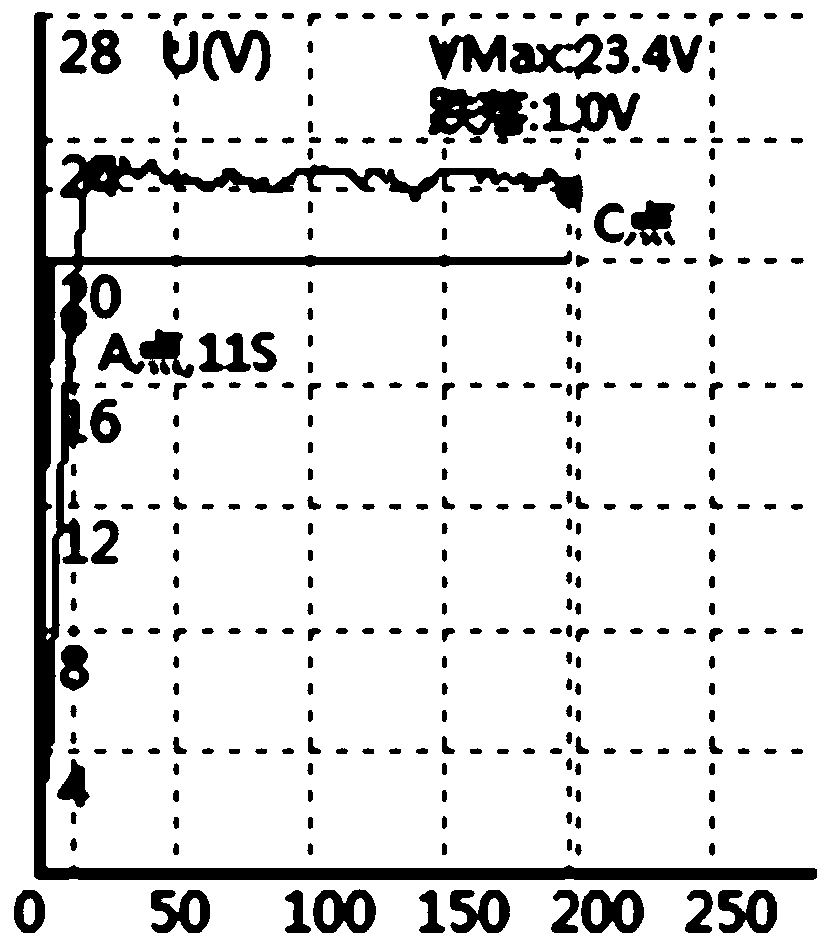

Embodiment 2

[0034] Connect two pieces of corroded aluminum foil to the positive and negative output terminals of the pulse power supply respectively, immerse in 12% ammonium adipate and 0.04% maleic acid solution at 80 °C, and set the temperature at 25V, 100mA·cm -2 , Continue to oxidize under the condition of 2Hz. After the applied voltage rises to 25V, the constant voltage value lasts for 5 minutes. Then the aluminum foil was heat-treated in an air atmosphere at 600°C for 2 minutes, and then heated at 25V, 20mA·cm -2 Under the conditions of DC anodizing, it was formed for 2 minutes.

[0035] Through the test, the specific capacity of the DC sample is increased by 2.5%, the leakage current is reduced by 19.8%, the power consumption is reduced by 21.1%, and the production efficiency is increased by 70%; the specific capacity of the pulse sample is increased by 4% and the leakage current is reduced under the same withstand voltage. 41.2%, power consumption is reduced by 10.4%, and produc...

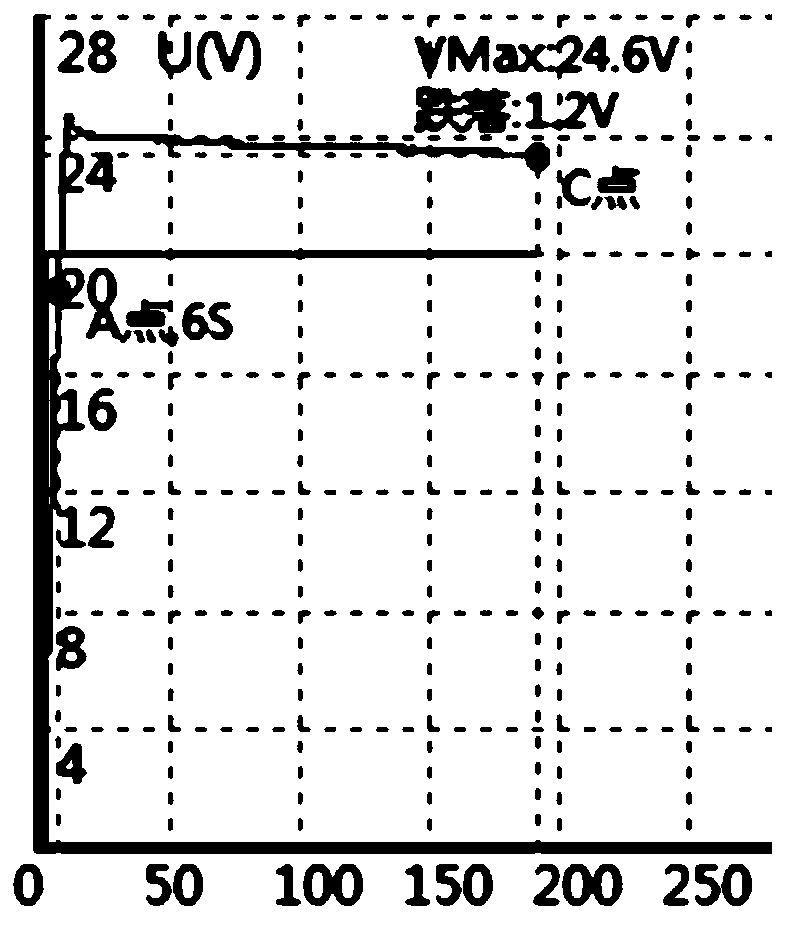

Embodiment 3

[0038] Connect two pieces of corroded foil to the positive and negative output ends of the pulse power supply respectively, immerse in 20% ammonium adipate and 0.5% ammonium oxalate solution at 75°C, at 51V, 130mA·cm -2, Continue to oxidize under the condition of 5Hz. After the applied voltage rises to 51V, the constant voltage value lasts for 6 minutes. Then the aluminum foil was heat-treated in an air atmosphere of 580°C for 2min, and then heated at 51V, 25mA·cm -2 Under the conditions of direct current anodizing, it was formed for 1min.

[0039] Through the test, the specific capacity of the DC sample is increased by 4.6%, the leakage current is reduced by 13%, the power consumption is reduced by 15%, and the production efficiency is increased by 80%; the specific capacity of the pulse sample is increased by 4% and the leakage current is reduced under the same withstand voltage. 27.2%, power consumption is reduced by 15.5%, and production efficiency is increased by 15%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com