Variable-frequency alternating-current anodic oxidation method for anode aluminum foil for aluminium electrolytic capacitor

An aluminum electrolytic capacitor, anodizing technology, applied in electrolytic capacitors, electrolytic capacitor manufacturing, anodizing and other directions, to achieve the effect of improving compactness, improving production efficiency, and repairing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Connect the two poles of the variable frequency AC power supply to their respective corroded aluminum foils, and immerse them in 20% ammonium azelate solution at 20°C, at 3V, 5A / cm 2 , Anodizing under the condition of 1000Hz. During the formation process, after the applied voltage increased to 3V, constant voltage anodization was carried out for 20min. Subsequently, the aluminum foil was heat-treated in an air atmosphere at 550° C. for 3 minutes, and then anodized for 2 minutes under the same conditions as above. Through the test, compared with the corroded aluminum foil after DC anodization, under the same withstand voltage, the specific capacitance value increases by 1%, the loss value decreases by 5%, and the production efficiency increases by 85%. The obtained anode aluminum foil leakage current parameter K=0.002μA·V -1 ·µF -1 .

Embodiment 2

[0024] Connect the two poles of the variable frequency AC power supply to their respective corroded aluminum foils, and immerse them in 10% ammonium adipate solution at 90°C, at 20V, 100mA / cm 2 , Anodizing under the condition of 5Hz. During the formation process, after the applied voltage increased to 20V, the constant voltage anodized for 10min. Subsequently, the aluminum foil was heat-treated in an air atmosphere at 550° C. for 3 minutes, and then anodized for 2 minutes under the same conditions as above. Through the test, compared with the corroded aluminum foil after DC anodization, under the same withstand voltage, the specific capacitance value increases by 1%, the loss value decreases by 1%, and the production efficiency increases by 85%. The obtained anode aluminum foil leakage current parameter K=0.005μA·V -1 ·µF -1 .

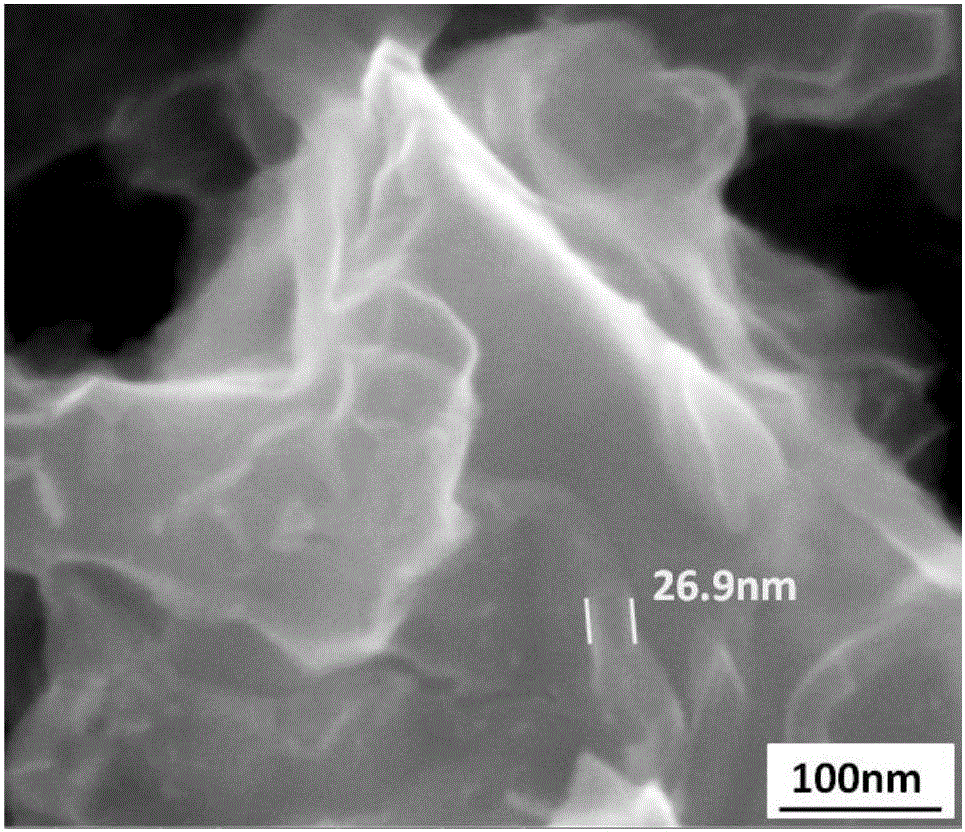

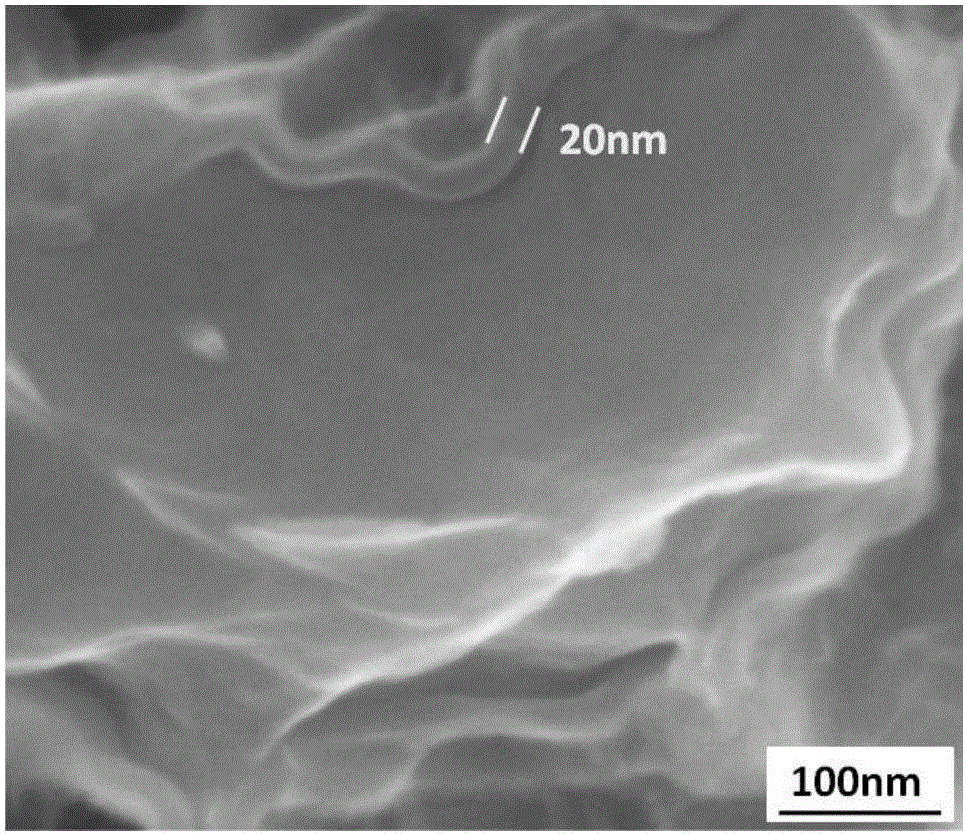

[0025] see figure 1 , 2 . in figure 1 It is a photograph of the cross-section morphology of the low-pressure corroded aluminum foil obtained by...

Embodiment 3

[0027] Connect the two poles of the variable frequency AC power supply to their respective corroded aluminum foils, immerse them in 1% citric acid solution at 70°C, 2 , Anodizing under the condition of 50Hz. During the formation process, after the applied voltage increased to 50V, constant voltage anodization was carried out for 5min. Subsequently, the aluminum foil was heat-treated in an air atmosphere at 600° C. for 2 minutes, and then anodized for 2 minutes under the same conditions as above. Through the test, compared with the corroded aluminum foil after DC anodization, under the same withstand voltage, the specific capacitance value increases by 2%, the loss value decreases by 5%, and the production efficiency increases by 100%. The obtained anode aluminum foil leakage current parameter K=0.008μA·V -1 ·µF -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com