Sandwich structure P (VDF-CTFE) composite film and preparation method thereof

A technology of VDF-CTFE and composite film, which is applied in chemical instruments and methods, flat products, and other household appliances, etc., which can solve the breakdown of composite materials, affect the use properties, weaken the toughness of polymer-based composite materials, and make the mechanical properties easy to process To achieve the effect of high breakdown field strength, improved polarization performance, and strong interfacial interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 0

[0040] HBPE-G-PMMA is hyperbranchedpolyethlene graftedPolyPolyPolyPoly PMMA, referred to as HBPE-G-PMMA, which is synthesized by laboratory, and the specific synthesis step is:

[0041] (1) Take net and strictly dry 100 ml Schlenk bottle, which was added to the proportion of 342 mmol MMA monomer, 12 ml of water-free toluene, 0.38 mmol of HBPE @ Br and 0.76 mmol of PMDeta.

[0042] (2) Frozen - evacuated - thawed three times to ensure the anhydrous anhydrous environment of the polymerization process, followed by rapid addition of 0.38 mmol of Cubr under a nitrogen atmosphere, and the seal was sealed at 90 ° C for 12 h.

[0043] (3) After the reaction is processed to a predetermined time, the reaction bottle is immersed in an ice water bath, and then the cold air is purged to dry, and the THF is added to dissolve the product, continue to add methanol to precipitate the product, and finally fall out of the supernatant liquid. Repeat this step 3 times to purify the product.

[0044] (...

Embodiment 1

[0046] Step 1: Trying 0.1 g of HBPE-G-PMMA in a glass bottle, add 10 mLDMF, stirred the auxiliary copolymer HBPE-G-PMMA, and then add 0.24 g of hexagonal boron tank (H-BN) powder. In the glass bottle, it was finally added to 50 ml DMF (with the mass of H-BN in the solvent), and the cap was sealed.

[0047] Step 2: Put the mixed mixture of steps in a room temperature in a room temperature in the ultrasonic cell, the ultrasonic power is selected from 240W.

[0048] Step 3: Take the mixture after the ultrasonic treatment in step II is removed into the centrifuge tube, centrifuged at 3000 rpm for 30 min, mainly removing unstripated block H-BN. The supernatant is then taken, ie the dispersion of boron nitride nanofilament (BNNSS).

[0049] Step 4: Take 40 ml of the dispersion liquid in step three, centrifuge at 7000 rpm in the centrifuge for 30 min, mainly, to remove excess HBPE-G-PMMA polymers, remove the upper layer, collect the bottom product in a vacuum oven to dry the supreme Heav...

Embodiment 2-4

[0056] The mass quality of step six in Example 1 was changed to 0.1 g (Example 2), 0.15 g (Example 3), 0.2 g (Example 4) PMMA is dissolved in 10 ml CHCl 3 In other conditions, the composite film material obtained by the three-layer structure is prepared.

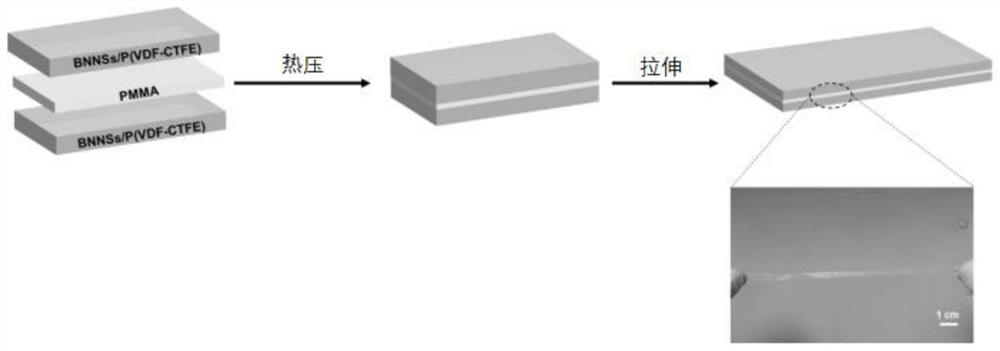

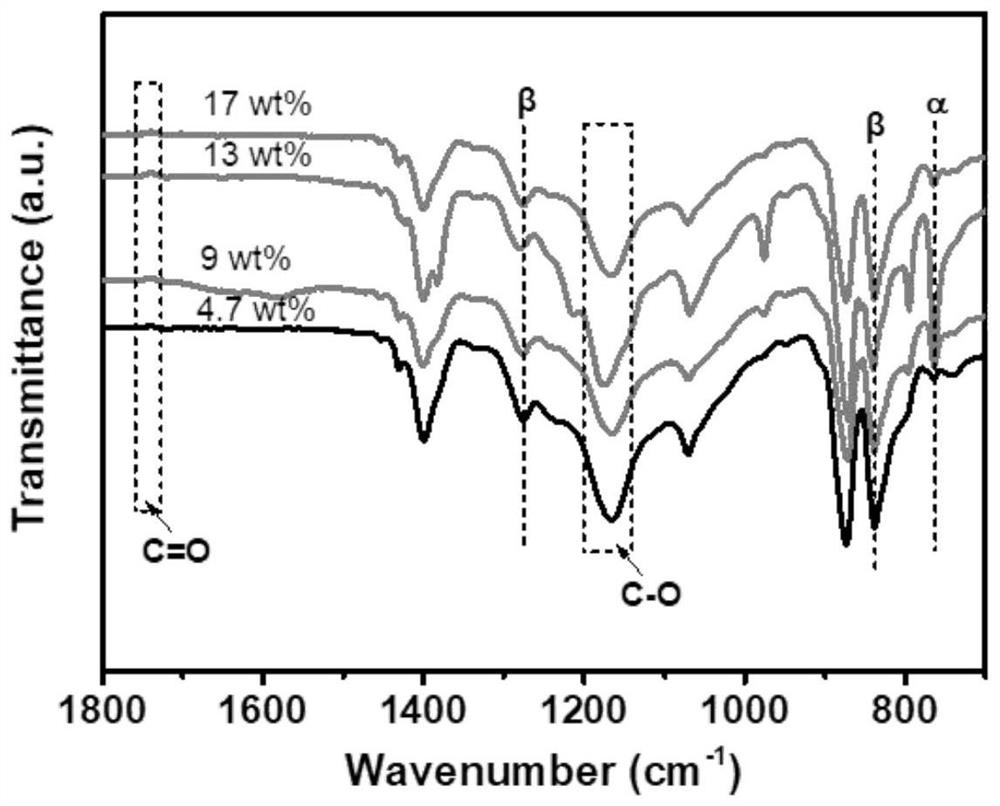

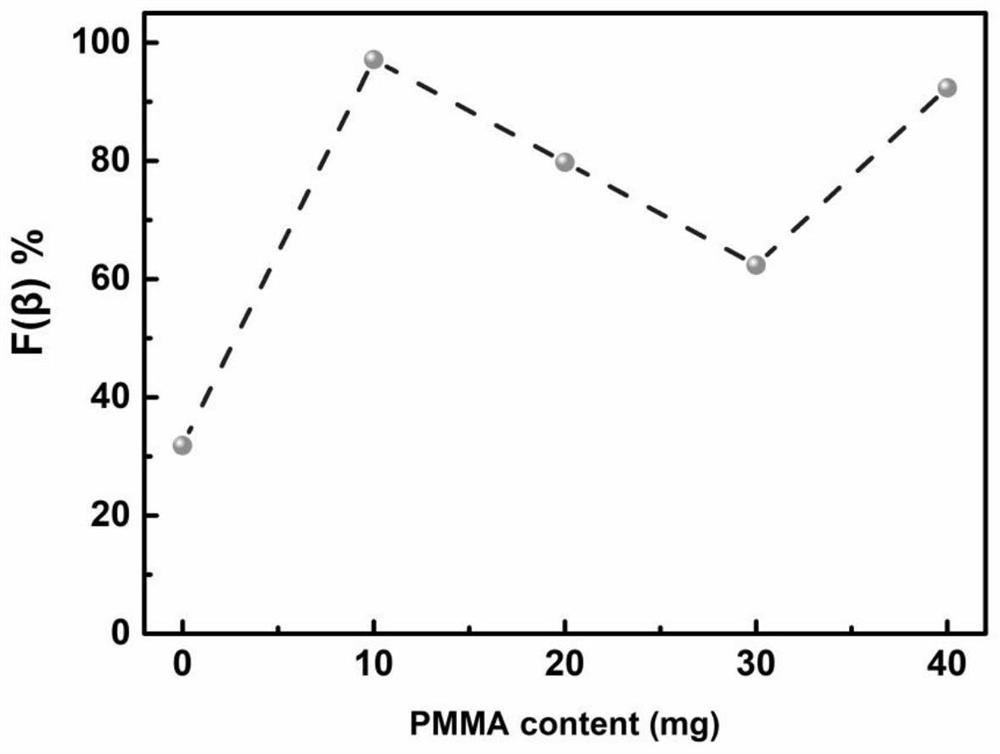

[0057] Schematic diagram of the preparation of the composite film material figure 1 As shown, from figure 1 It can be seen that the three-layer composite film has good toughness. figure 2 For the infrared spectrum of the composite film, image 3 The relative content of the β phase calculated by the LAMBERT-BEER law can be seen that f (β) = 31.8% in the two-layer structure of the intermediate non-PMMA layer, and with the increase of the intermediate PMMA content, when the middle PMMA mass is 10mg The content of β phase increases to 97%; then the content of the β phase is slowly decreased, but the overall content is higher than the β-phase content of the two composite films. At the same time, the dielectric constant and dielectric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com