Energy storage niobate microcrystalline glass dielectric material and preparation method thereof

A technology of glass-ceramics and dielectric materials, applied in the field of energy storage dielectric materials, can solve problems such as high breakdown field strength dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

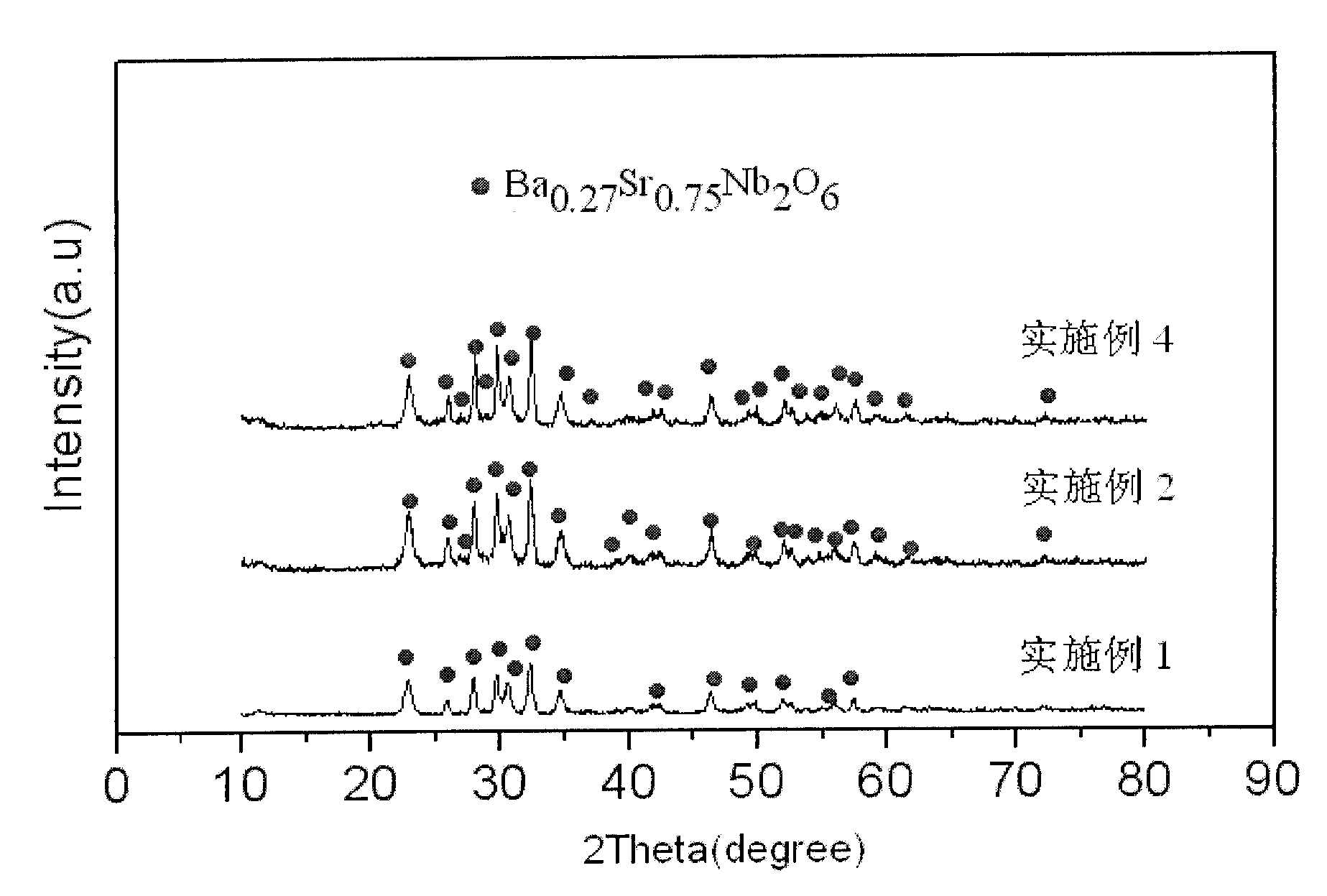

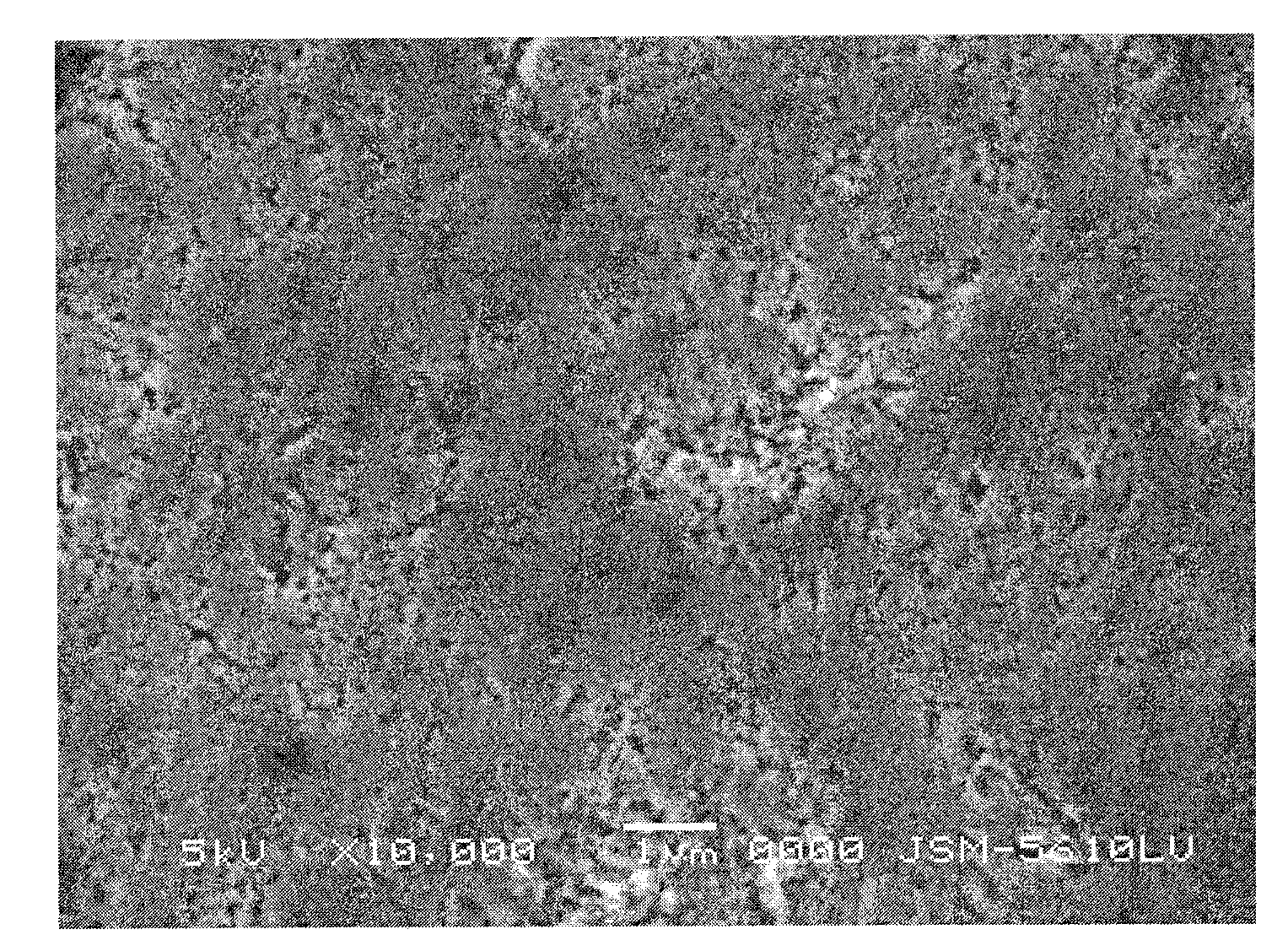

Embodiment 1

[0025] An environment-friendly energy storage niobate glass-ceramic dielectric and a preparation method thereof, wherein there is no admixture XY in its composition 2 .

[0026] (1) BaCO with a purity greater than 98.5% 3 , SrCO 3 、Na 2 CO 3 , Nb 2 o 5 , SiO 2 、H 3 BO 3 as raw material, according to Na 2 O:SrO:BaO:Nb 2 o 5 : SiO 2 :B 2 o3 =a:b:c:d:e:f (where a=0.05, b=c=0.21, d=0.18, e=0.3, f=0.05, a+b+c+d+e+f=1) The mol ratio batching, all raw material total consumptions are 100 grams. Then these raw materials are added into a ball mill with ball milling media (zirconia balls and absolute ethanol) to grind for 6 hours, dried and then kept at 1530° C. for 3 hours to melt into molten glass;

[0027] (2) quickly pour the high-temperature molten glass obtained in step (1) into a rectangular or circular mold made of copper material, then anneal for 10 hours to eliminate stress, and finally cut into glass flakes with a thickness of 0.5 mm;

[0028] (3) Perform contr...

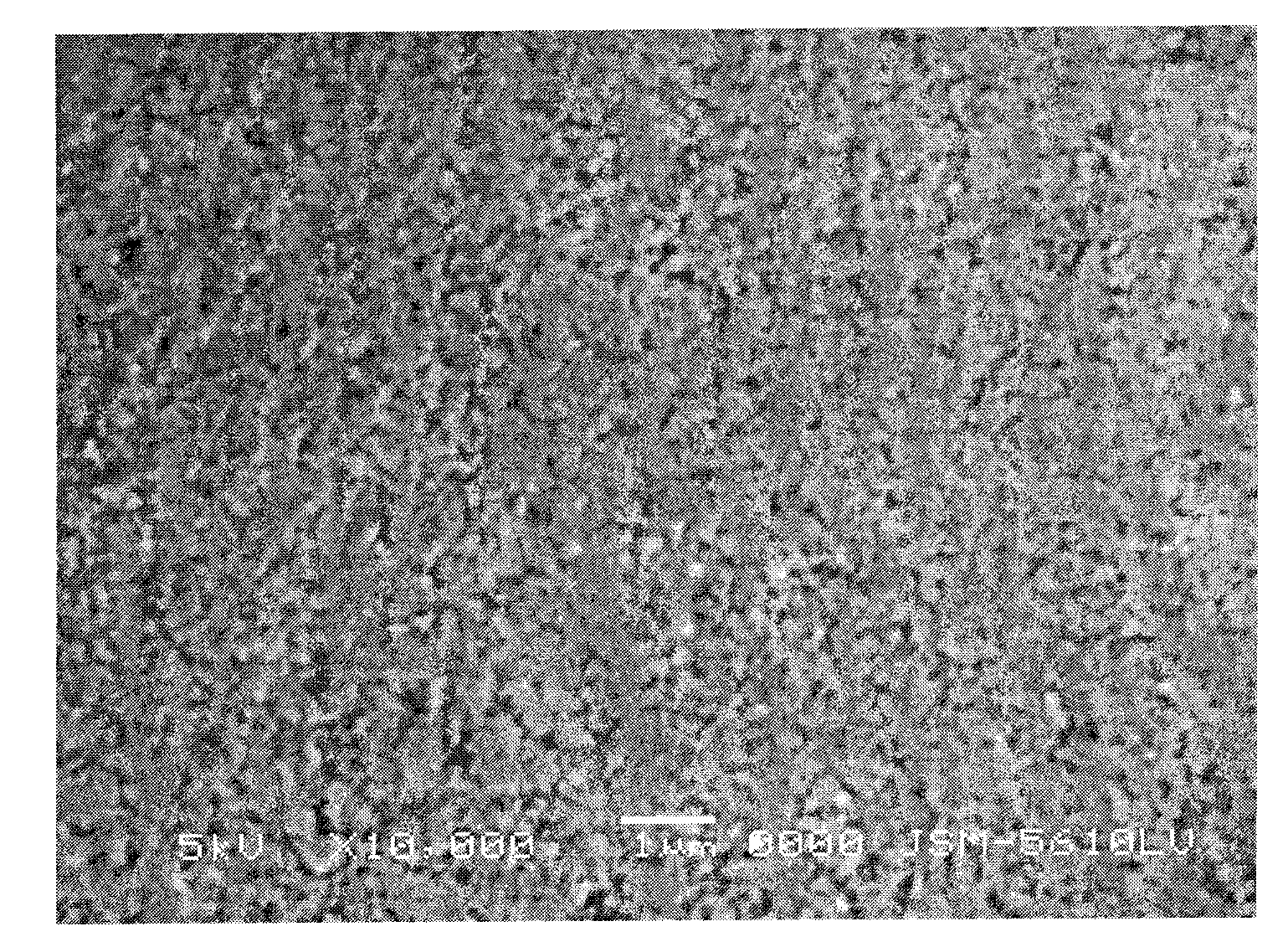

Embodiment 2

[0032] A kind of environment-friendly energy storage niobate glass-ceramics dielectric and preparation method thereof, there is no Na in its composition 2 O and admixture XY 2 .

[0033] (1) BaCO with a purity greater than 98.5% 3 , SrCO 3 , Nb 2 o 5 , SiO 2 、H 3 BO 3 As raw material, according to SrO: BaO: Nb 2 o 5 : SiO 2 :B 2 o 3 =b:c:d:e:f (wherein b=c=0.225, d=0.2, e=0.3, f=0.05, a+b+c+d+e+f=1), all The total consumption of raw materials is 100 grams. Then these raw materials are added into a ball mill with ball milling media (zirconia balls and absolute ethanol) to grind for 6 hours, dried and then kept at 1550°C for 3 hours to melt into molten glass;

[0034] (2) quickly pour the high-temperature molten glass obtained in step (1) into a metal mold, then anneal for 10 hours to eliminate stress, and finally cut into glass flakes with a thickness of 0.3-0.5 mm;

[0035] (3) Perform controlled crystallization on the glass flakes prepared in step (2). The crys...

Embodiment 3

[0039] An environment-friendly energy storage niobate glass-ceramic dielectric and a preparation method thereof, wherein there is no admixture XY in its composition 2 .

[0040] (1) BaCO with a purity greater than 98.5% 3 , SrCO 3 、Na 2 CO 3 , Nb 2 o 5 , SiO 2 、H 3 BO 3 as raw material, according to Na 2 O:SrO:BaO:Nb 2 o 5 : SiO 2 :B 2 o 3 =a:b:c:d:e:f (where a=0.05, b=c=0.21, d=0.18, e=0.3, f=0.05, a+b+c+d+e+f=1) The mol ratio batching, all raw material total consumptions are 100 grams. Then these raw materials are added into a ball mill with ball milling media (zirconia balls and absolute ethanol) to grind for 6 hours, dried and then kept at 1530°C for 2 hours to melt into molten glass;

[0041] (2) quickly pour the high-temperature glass liquid obtained in step (1) into a metal mold, then anneal for 10 hours to eliminate stress, and finally cut into glass flakes with a thickness of 0.5 mm;

[0042] (3) Controlled crystallization of the glass flakes prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com