Novel niobate-base glass ceramic energy-storing material and preparation method and application thereof

A technology for energy storage materials and glass ceramics, which is applied in the field of new niobate-based glass ceramic energy storage materials and their preparation, and can solve the problems of low breakdown field strength, uneven composition, and complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

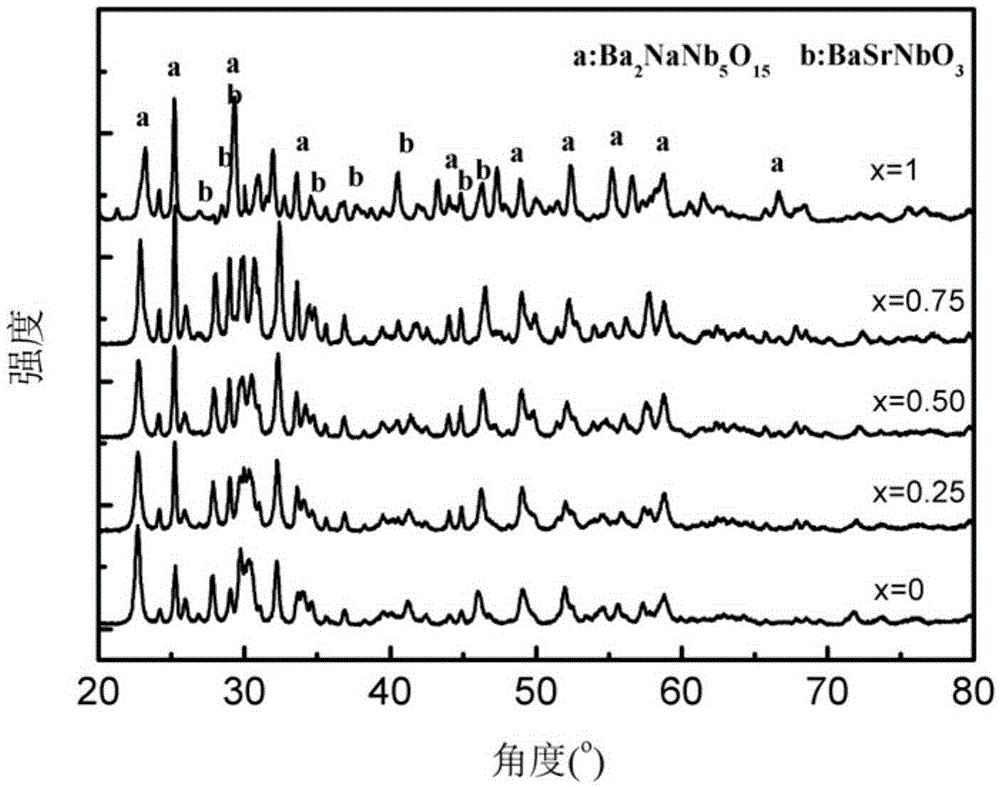

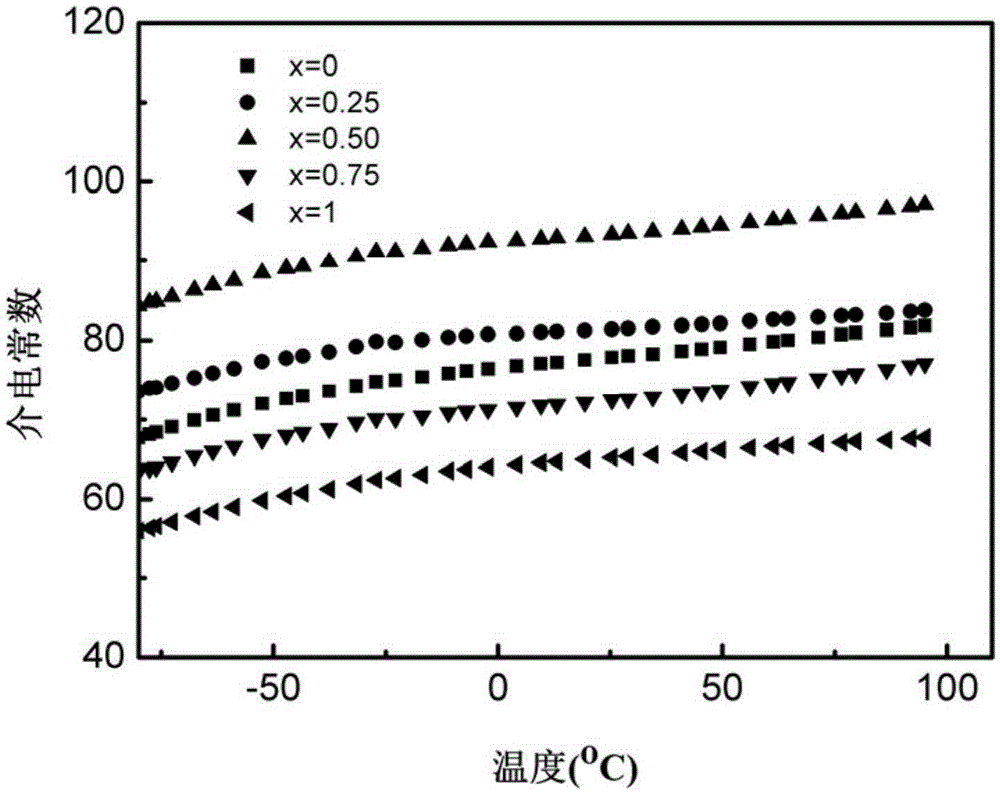

[0025] Example 1 (x=0)

[0026] Niobate Glass Ceramics 6Na with High Energy Storage Density 2 O-24BaO-30Nb 2 o 5 -40SiO 2

[0027] (1) with analytically pure BaCO 3 , NaCO 3 , Nb 2 o 5 , SiO 2 Powder as raw material, according to the designed chemical composition 6Na 2 O-24BaO-30Nb 2 o 5 -40SiO 2 The mass of each component is weighed, and the total mass of the sample is 80-100 grams.

[0028] (2) Select anhydrous ethanol as the dispersant, use agate balls to mill in a polytetrafluoroethylene ball mill tank at a speed of 50-60 rpm, and dry the evenly mixed slurry. The time of ball milling is 20~30h, and the ratio of ball to material during ball milling is (1.0~1.5):1.

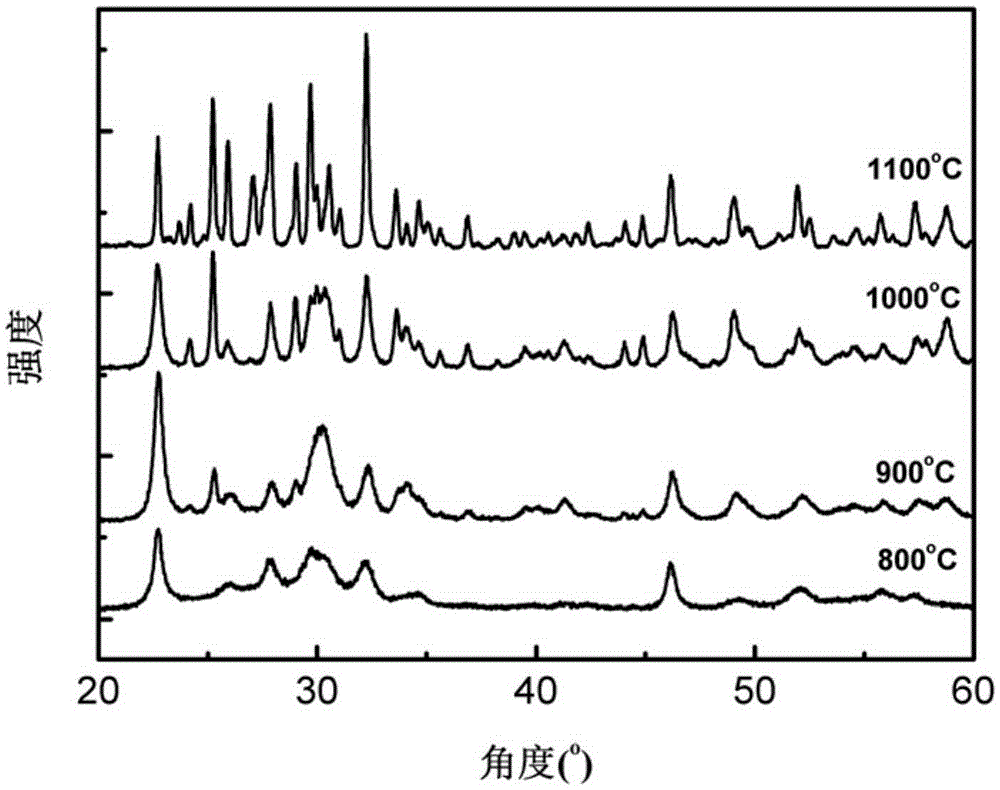

[0029] (3) Put the dried glass raw material into the crucible for high-temperature melting, the heating rate of the high-temperature furnace is 1400° C., and the high-temperature melting time is 5 hours. Then the high-temperature melt is quickly poured into the preheated copper mold to obtain a tr...

Embodiment 2

[0032] Example 2 (x=0.25)

[0033] Niobate Glass Ceramics 6Na with High Energy Storage Density 2 O-18BaO-6SrO-30Nb 2 o 5 -40SiO 2

[0034] (1) with analytically pure BaCO 3 , SrCO 3 , NaCO 3 , Nb 2 o 5 , B 2 o 3 、Al 2 o 3 , SiO 2 Powder as raw material, according to the designed chemical composition 6Na 2 O-18BaO-6SrO-30Nb 2 o 5 -40SiO 2 The mass of each component is weighed, and the total mass of the sample is 80-100 grams.

[0035] (2) Select anhydrous ethanol as the dispersant, use agate balls to mill in a polytetrafluoroethylene ball mill tank at a speed of 50-60 rpm, and dry the evenly mixed slurry. The time of ball milling is 20~30h, and the ratio of ball to material during ball milling is (1.0~1.5):1.

[0036] (3) Put the dried glass raw material into the crucible for high-temperature melting, the heating rate of the high-temperature furnace is 1500° C., and the high-temperature melting time is 5 hours. Then the high-temperature melt is quickly poure...

Embodiment 3

[0039] Example 3 (x=0.50)

[0040] Niobate Glass Ceramics 6Na with High Energy Storage Density 2 O-12BaO-12SrO-30Nb 2 o 5 -40SiO 2

[0041] (1) with analytically pure BaCO 3 , SrCO 3 , NaCO 3 , Nb 2 o 5 , SiO 2 Powder as raw material, according to the designed chemical composition 6Na 2 O-12BaO-12SrO-30Nb 2 o 5 -40SiO 2 The mass of each component is weighed, and the total mass of the sample is 80-100 grams.

[0042] (2) Select anhydrous ethanol as the dispersant, use agate balls to mill in a polytetrafluoroethylene ball mill tank at a speed of 50-60 rpm, and dry the evenly mixed slurry. The time of ball milling is 20~30h, and the ratio of ball to material during ball milling is (1.0~1.5):1.

[0043] (3) Put the dried glass raw material into the crucible for high-temperature melting, the heating rate of the high-temperature furnace is 1600° C., and the high-temperature melting time is 2 hours. Then the high-temperature melt is quickly poured into the preheated c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breakdown field strength | aaaaa | aaaaa |

| Energy storage density | aaaaa | aaaaa |

| Breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com