Mould for using two-dimensional fiber fabric to produce blanks of carbon-carbon composite barrel products

A technology of carbon composite materials and fiber fabrics, which is applied in the field of molds for preparing cylindrical product blanks, can solve problems such as easy delamination and deformation of products, product density that does not meet requirements, and reduced product quality, so as to solve cracking and separation. layers, stable product quality and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

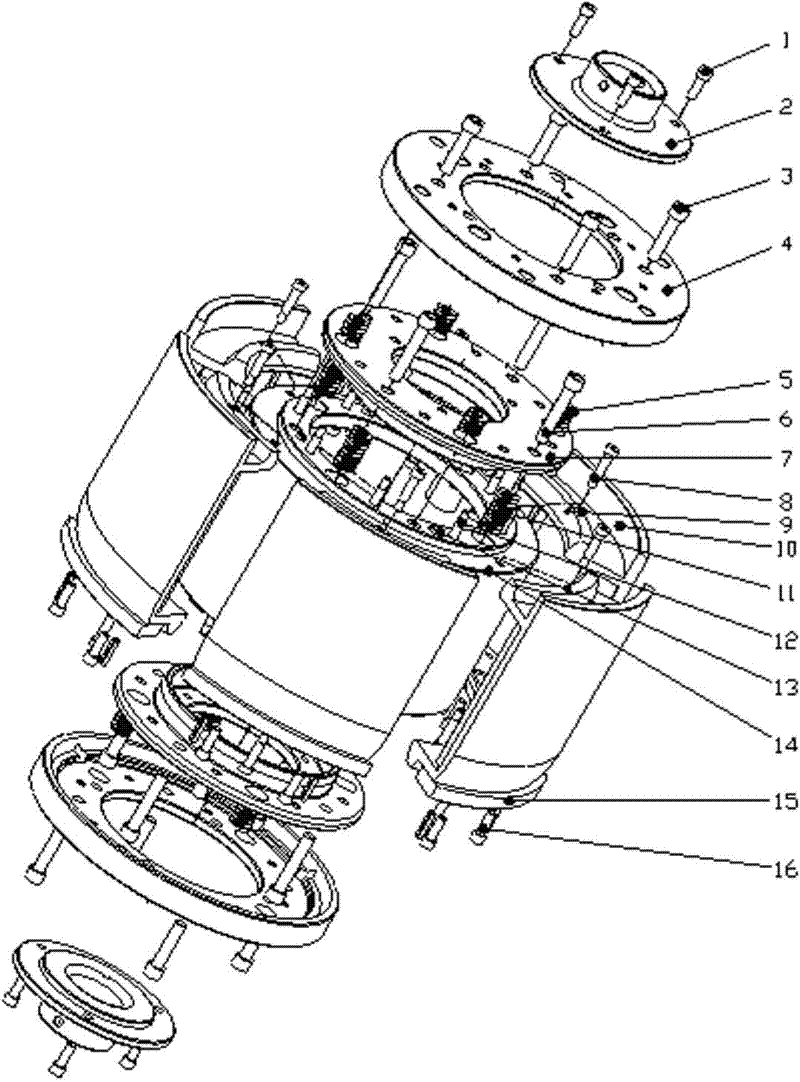

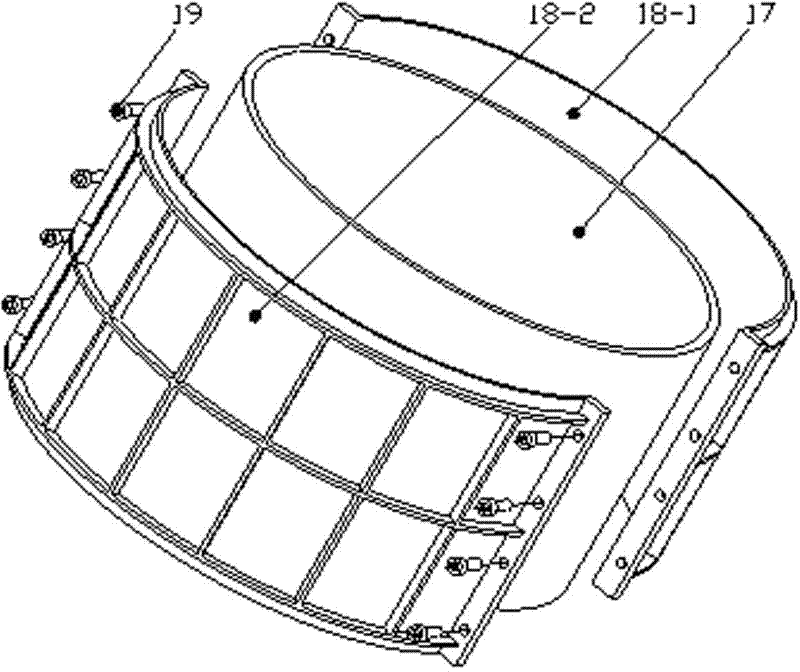

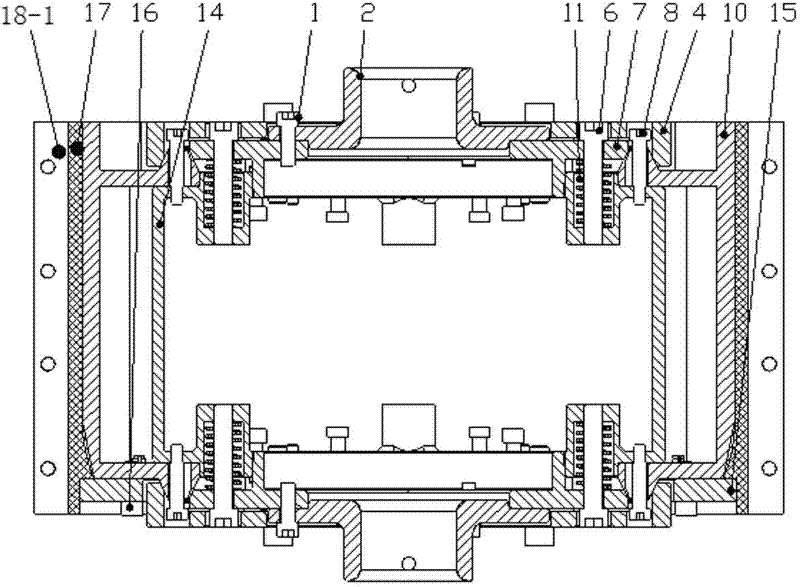

[0016] With reference to the accompanying drawings, the mold for preparing the carbon-carbon composite cylinder product green body with two-dimensional fiber fabrics in this embodiment includes an inner mold and an outer mold, and the inner mold includes a slider 10, an inner support cylinder 14, an inner pressure Block 7, outer pressure block 4, mold mounting flange 2, the mold mounting flange 2 is connected with the outer pressure block 4 through screw I1, and the outer pressure block 4 is connected with the inner pressure block 7 through screw II3 and spring I5, The inner pressure block 7 is connected with the inner support cylinder 14 through the screw III6 and the spring II11, the slider 10 is connected with the inner support cylinder 14 through the screw IV8, and the outer mold is composed of the valve mold I18-1 and the valve mold II18-2 And conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com