Carbon/carbon composite material as well as preparation method and application thereof

A carbon composite material and carbon composite technology, applied in the field of composite material preparation, can solve the problems of easy generation of stress, degradation of high temperature resistance and mechanical properties, difficulty in achieving thermal matching, etc., to achieve excellent high temperature oxidation resistance and improve high temperature oxidation resistance. performance, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] One embodiment of the present invention provides a method for preparing a carbon / carbon composite material, including the following steps S10-S30.

[0036] Step S10 , carbon deposition and silicon carbide deposition are sequentially performed on the carbon fiber preform by chemical vapor deposition to obtain a carbon / carbon composite rough body containing silicon carbide.

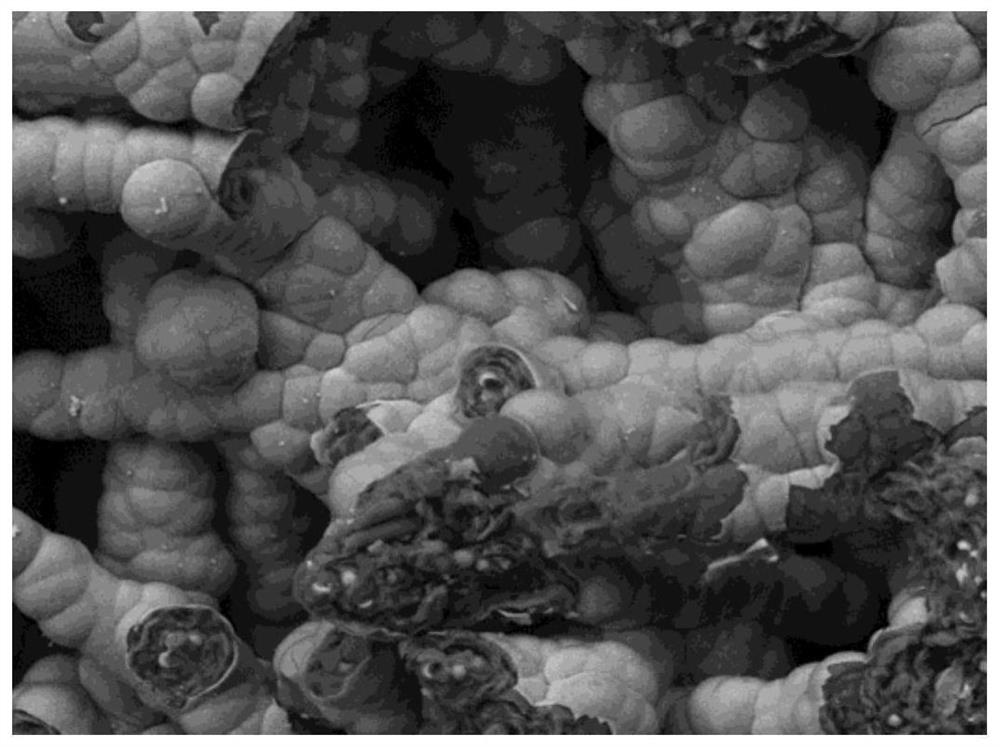

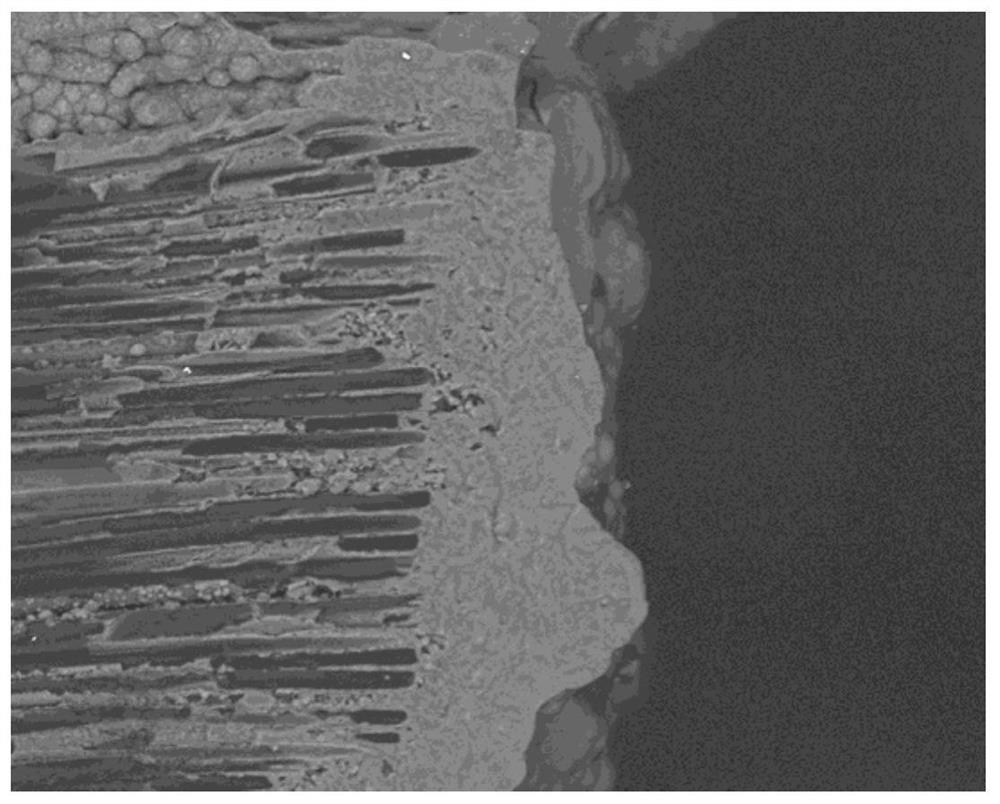

[0037] First, the carbon fiber preform is subjected to carbon deposition and silicon carbide deposition in sequence by chemical vapor deposition to obtain a rough body; the carbon deposition step densifies the carbon fiber preform to obtain a uniformly dense carbon / carbon composite body, and then through chemical vapor phase The silicon carbide deposition method is used to obtain a uniform silicon carbide layer.

[0038] In some of these embodiments, the carbon fiber preform used in step S10 is made of carbon fiber cloth and carbon fiber mesh by alternate needle punching; further, the density of the ca...

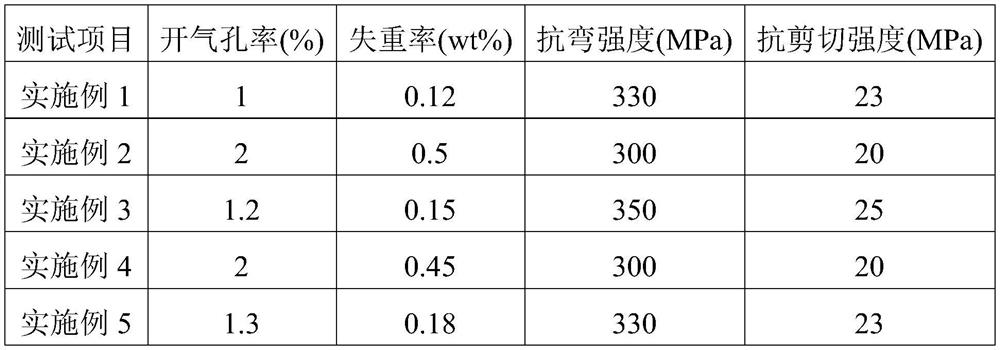

Embodiment 1

[0069] 1) T700 carbon fiber interwoven cloth and carbon fiber mesh tire are alternately laminated and needle-punched to prepare a carbon fiber preform, and the density of the carbon fiber preform is 0.45g / cm 3 .

[0070] 2) Put the carbon fiber prefabricated body obtained in step 1) into a chemical vapor deposition furnace, set the deposition temperature to 1100°C, use natural gas as the carbon source, and the natural gas flow rate to be 3m 3 / h, the furnace pressure is 1500Pa, the insulation deposition is 100h, and the density is 1.0g / cm 3 Densified carbon / carbon composite body.

[0071] 3) Put the densified carbon / carbon composite green body obtained in step 2) into a silicon carbide deposition furnace for silicon carbide deposition treatment, using trichloromethylsilane as the silicon source, the deposition temperature is 900°C, and the deposition pressure is 1000Pa, thermal insulation deposition for 30h, the obtained density is 1.3g / cm 3 Carbon / carbon composite blanks c...

Embodiment 2

[0077] 1) T700 carbon fiber interwoven fabric and carbon fiber net tire are alternately stacked and needle-punched to prepare a carbon fiber preform, and the density of the carbon fiber preform is 0.4g / cm 3 .

[0078] 2) Put the carbon fiber prefabricated body obtained in step 1) into a chemical vapor deposition furnace, set the deposition temperature to 1000°C, use natural gas as the carbon source, and the natural gas flow rate to be 3m 3 / h, the furnace pressure is 1500Pa, and the insulation deposition is 100h, and the density is 0.9g / cm 3 Densified carbon / carbon composite body.

[0079] 3) Put the densified carbon / carbon composite green body obtained in step 2) into a silicon carbide deposition furnace for silicon carbide deposition treatment, using trichloromethylsilane as the silicon source, the deposition temperature is 1000°C, and the deposition pressure is 500Pa, thermal insulation deposition for 50h, the obtained density is 1.25g / cm 3 Carbon / carbon composite blanks...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com