Alumina ceramic, preparation method thereof and ceramic bearing

A kind of technology of alumina ceramics and alumina, applied in the field of ceramic materials, can solve the problems of low fracture toughness and difficult slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

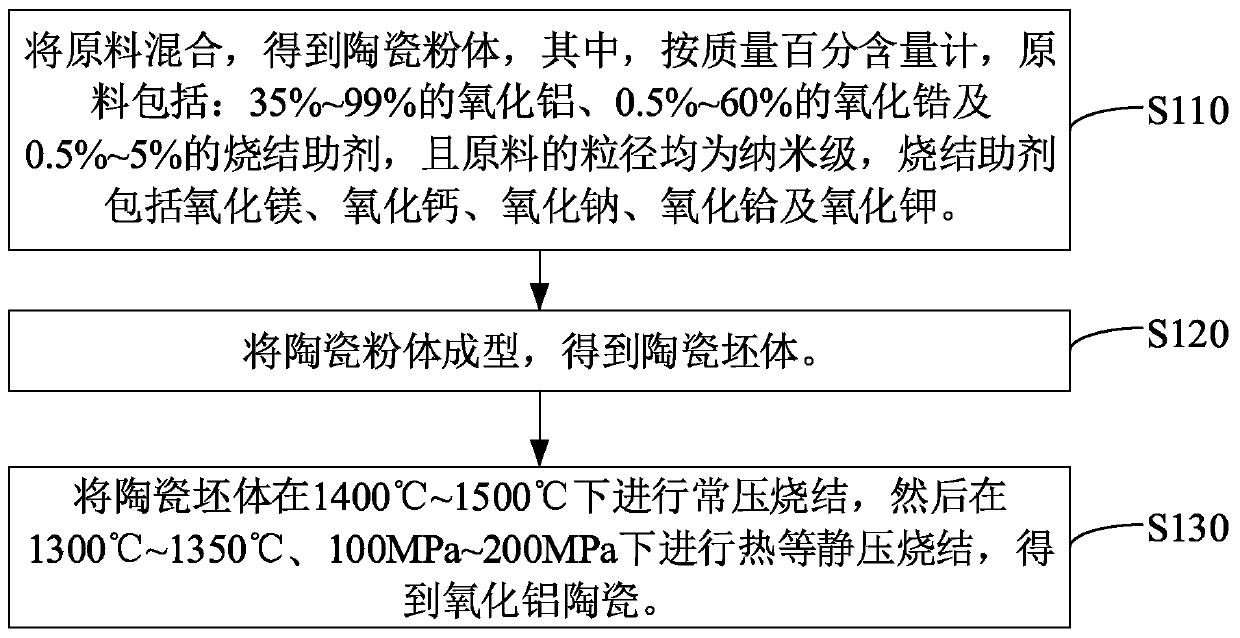

[0023] see figure 1 , the preparation method of alumina ceramics of an embodiment, comprises the steps:

[0024] Step S110: Mix the raw materials to obtain ceramic powder, wherein, in terms of mass percentage, the raw materials include: 35%-99% alumina, 0.5%-60% zirconia and 0.5%-5.0% sintering aid sintering aids, and the particle size of the raw materials is nanoscale, and the sintering aids include magnesium oxide, calcium oxide, sodium oxide, hafnium oxide and potassium oxide.

[0025] By adding zirconia, zirconia is distributed in the alumina matrix. Due to the difference in expansion coefficient between alumina and zirconia, the stress on the zirconia particles is relaxed during sintering and cooling, and the tetragonal phase is transformed into a monoclinic phase. The volume expands, thereby producing microcracks, achieving the effect of toughening alumina and improving the strength of alumina ceramics.

[0026] The above-mentioned sintering aid can effectively inhibit...

Embodiment 1

[0050] The preparation process of the alumina ceramics of the present embodiment is specifically as follows:

[0051] (1) In terms of mass percentage, the following raw materials are weighed: 94.5% Al 2 o 3 , 5.0% ZrO 2 And 0.5% sintering aid, wherein, the sintering aid is 0.1% MgO, 0.1% CaO, 0.1% Na 2 O, 0.1% Hf 2 O and 0.1% K 2 O mixture. Then mix the above-mentioned raw materials with zirconia balls and alcohol in a mass ratio of 1:2:1, and wet-mill in a high-energy ball mill for 48 hours, then dry at 60°C for 24 hours, and pass through a 300-mesh sieve to obtain a ceramic powder .

[0052] (2) The ceramic powder is subjected to cold isostatic pressing, and then dried at 100° C. and debinding at 700° C. to obtain a ceramic green body.

[0053] (3) First sinter the ceramic green body at 1400°C under normal pressure for 2h, and then use nitrogen as the pressurized medium to perform hot isostatic pressing at 1350°C and 100MPa for 1h to obtain alumina ceramics.

Embodiment 2

[0055] The preparation process of the alumina ceramics of the present embodiment is specifically as follows:

[0056] (1) In terms of mass percentage, the following raw materials are weighed: 35% Al 2 o 3 , 60% ZrO 2 And 5.0% sintering aid, wherein, the sintering aid is 1.0% MgO, 1.0% CaO, 1.0% Na 2 O, 1.0% Hf 2 O and 1.0% K 2 O mixture. Then mix the above-mentioned raw materials with zirconia balls and alcohol in a mass ratio of 1:2:1, and wet-mill in a high-energy ball mill for 48 hours, then dry at 60°C for 24 hours, and pass through a 300-mesh sieve to obtain a ceramic powder .

[0057] (2) The ceramic powder is subjected to cold isostatic pressing, and then dried at 100° C. and debinding at 700° C. to obtain a ceramic green body.

[0058] (3) First sinter the ceramic green body at 1400°C under normal pressure for 2h, and then use nitrogen as the pressurized medium to perform hot isostatic pressing at 1350°C and 100MPa for 1h to obtain alumina ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com