Ultra-large-size carbon/carbon composite material sheet and equipment for preparing the same

A composite material sheet, super-sized technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, to achieve the effect of small deformation, near-net shape, guarantee stability and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

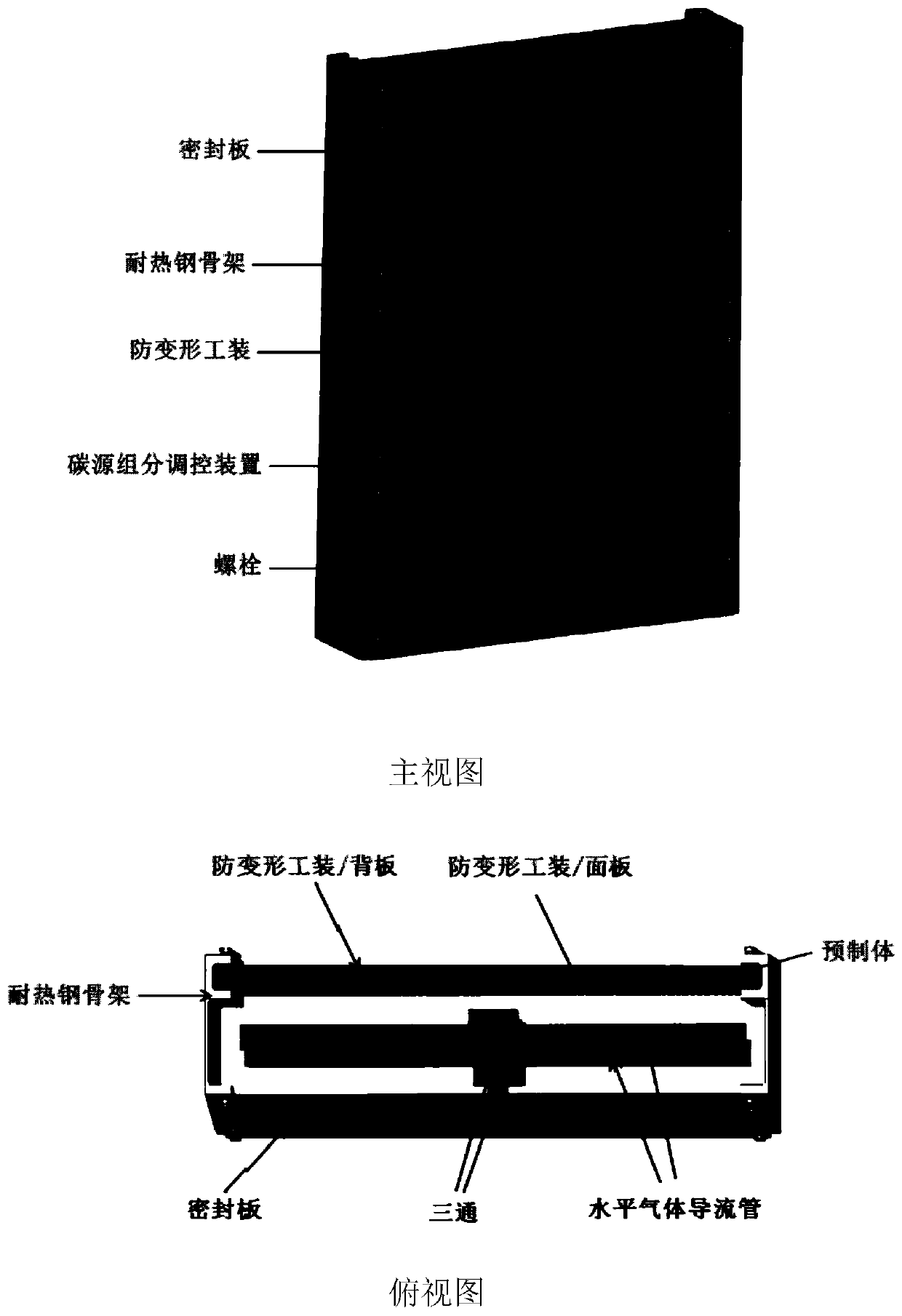

[0050] The super-sized carbon / carbon composite material sheet prepared in this example adopts a bulk density of 0.15g / cm 3 , Carbon felt with a size of 3500*1500*10mm is used as a carbon fiber prefabricated body, supported by anti-deformation tooling, assisted by a reactor and a carbon source component control device, and densified by chemical vapor deposition, as follows:

[0051] (1) First, the carbon fiber preform is supported between the anti-deformation tooling and a 10mm spacer is set; then two U-shaped grooves with side-wing heat-resistant steel skeleton are used to fix the anti-deformation tooling holding the carbon fiber prefab by bolts; The two heat-resistant steel skeletons are connected and fixed, and they are hoisted into the deposition furnace chamber.

[0052] (2) Two sets of carbon source component control devices are set inside the reaction chamber, one set is set at the bottom of the reaction chamber (gas path 1), and the other set is set at a height of 2000 ...

Embodiment 2

[0056] The super-sized carbon / carbon composite material sheet prepared in this example adopts a bulk density of 0.46g / cm 3 , The carbon fiber integral needle-punched felt with a size of 3500*1500*15mm is densified by chemical vapor deposition through the support of anti-deformation tooling, the reactor and the carbon source component control device, and the details are as follows:

[0057] (1) First, the carbon fiber preform is supported between the anti-deformation tooling and a 15mm spacer is set; then two U-shaped grooves with side-wing heat-resistant steel skeleton are used to fix the anti-deformation tooling holding the carbon fiber prefab by bolts; The two heat-resistant steel skeletons are connected and fixed, and they are hoisted into the deposition furnace chamber.

[0058] (2) Two sets of carbon source component control devices are set inside the reaction chamber, one set is set at the bottom of the reaction chamber (gas path 1), and the other set is set at a height ...

Embodiment 3

[0062] Other conditions in this example are the same as those in Example 2, except that the deposition time is increased. After 450h of vapor deposition, the super-large carbon / carbon composite material sheet of the present invention is obtained, and the overall bulk density of the sheet is 1.41g / cm 3 , the densification uniformity is ±0.04g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com