High-purity gadolinium hexaboride polycrystal and preparation method thereof

A technology of hexaboride and gadolinium boride, which is applied in the polycrystalline field of gadolinium hexaboride, can solve the problems of impurities and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

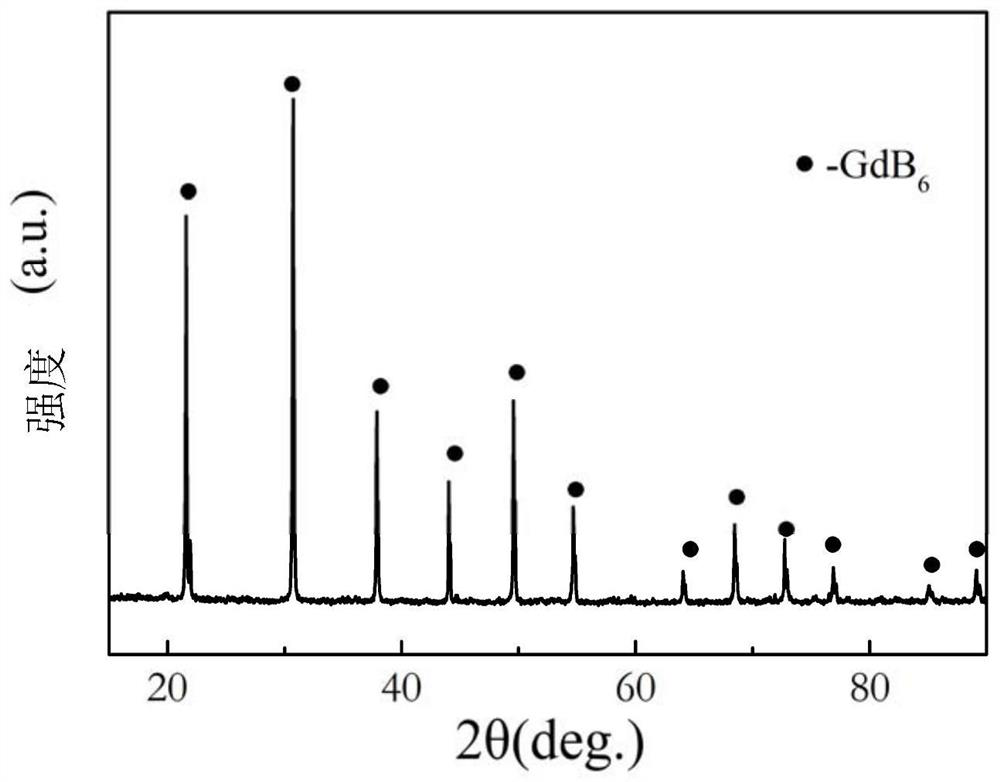

Embodiment 1

[0035] In the first step, weigh GdH in the glove box according to the molar ratio of 1:6 2 Mix well with boron powder (GdH 2 Both the purity of boron powder and boron powder are 99.5-99.9%, and the particle size is 360 mesh, both purchased from Hunan Institute of Rare Earth Metal Materials). Use the QM-QX2 planetary high-energy ball mill to mill for 3 hours at a rotational speed of 350r / min, wherein every 30 minutes of ball milling, stop for 5 minutes and rotate in reverse to refine the powder and fully mix it.

[0036] The second step: the mixed powder was loaded into a graphite mold in a glove box, followed by spark plasma sintering (SPS) (LABOX-350, Sinter Land Inc., Japan) in-situ reaction sintering.

[0037] Among them, the sintering process is divided into four stages.

[0038] The first stage is the dehydrogenation reaction stage, at a temperature of 973K, GdH 2 The powder is dehydrogenated to form Gd metal element, wherein the pressure is 3MPa, the reaction time is ...

Embodiment 2

[0044] In the first step, weigh GdH in the glove box according to the molar ratio of 1:6 2 Mix well with boron powder (GdH 2 Both the purity of boron powder and boron powder are 99.5-99.9%, and the particle size is 360 mesh, both purchased from Hunan Rare Earth Metal Material Research Institute), the atmosphere of the glove box is high-purity argon with a purity ≥ 99.99%, and the oxygen content is lower than 10ppm; using QM -QX2 planetary high-energy ball mill ball mill for 3 hours, rotating speed 350r / min, among which every 30 minutes of ball milling, stop for 5 minutes and reverse rotation, so that the powder is refined and fully mixed.

[0045] The second step: the mixed powder was loaded into a graphite mold in a glove box, followed by spark plasma sintering (SPS) (LABOX-350, Sinter Land Inc., Japan) in-situ reaction sintering.

[0046] The sintering process is divided into four stages.

[0047] The first stage is the dehydrogenation reaction stage, at a temperature of 1...

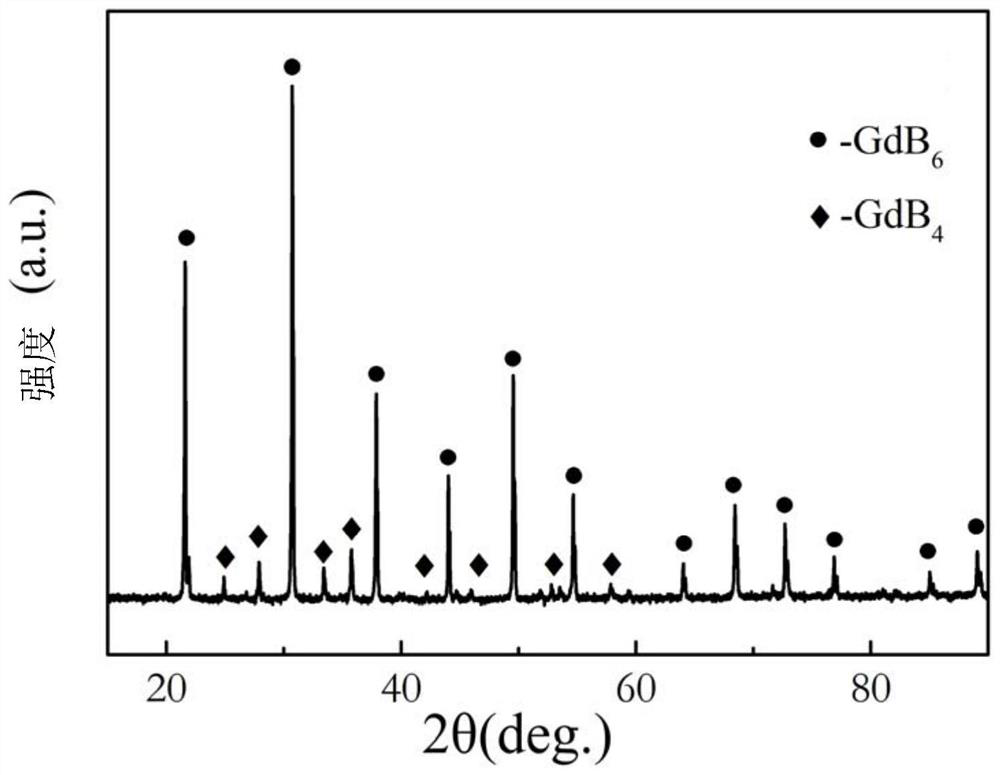

Embodiment 3

[0053] In the first step, weigh GdH in the glove box according to the molar ratio of 1:6 2 Mix well with boron powder (GdH 2 Both the purity of boron powder and boron powder are 99.5-99.9%, and the particle size is 360 mesh, both purchased from Hunan Institute of Rare Earth Metal Materials). Use the QM-QX2 planetary high-energy ball mill to mill for 3 hours at a rotational speed of 350r / min, wherein every 30 minutes of ball milling, stop for 5 minutes and rotate in reverse to refine the powder and fully mix it.

[0054] The second step: the mixed powder was loaded into a graphite mold in a glove box, followed by spark plasma sintering (SPS) (LABOX-350, Sinter Land Inc., Japan) in-situ reaction sintering.

[0055] The sintering process is divided into four stages.

[0056] The first stage is the dehydrogenation reaction stage, at a temperature of 1173K, GdH 2 The powder is dehydrogenated to form a Gd metal element, wherein the pressure is 5 MPa, the reaction time is 5 minute...

PUM

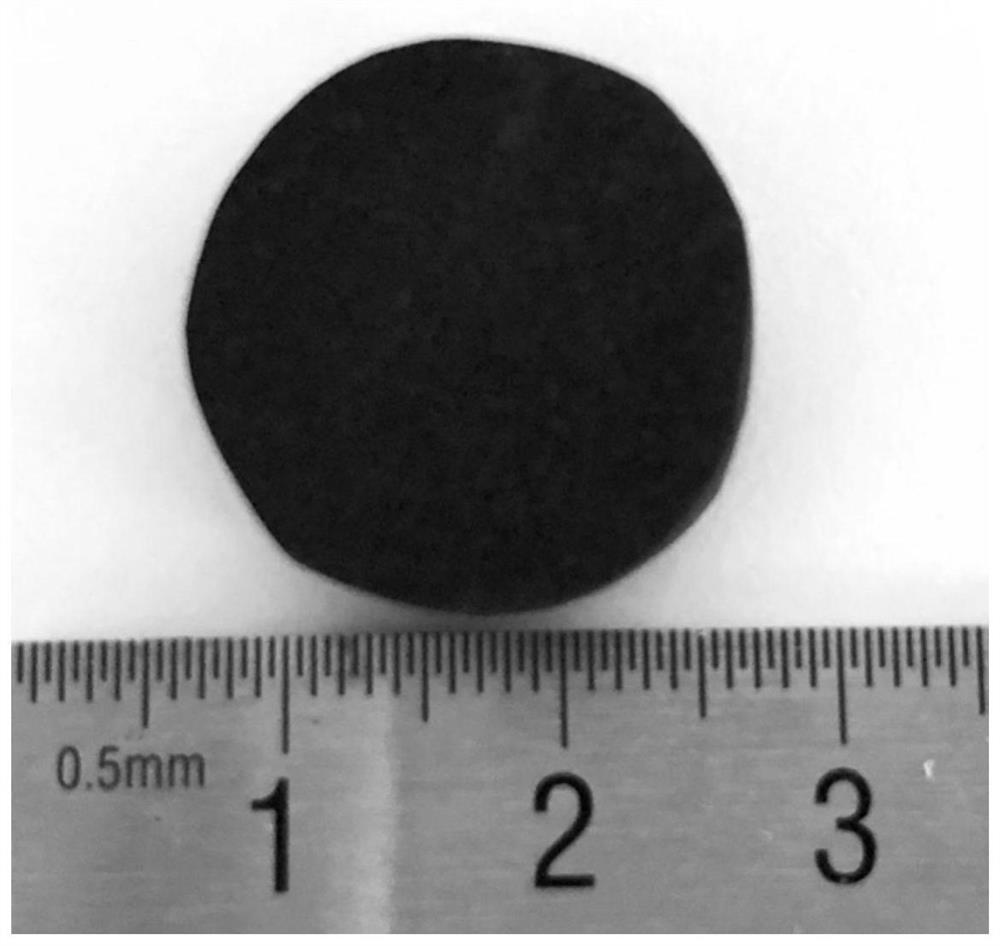

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com