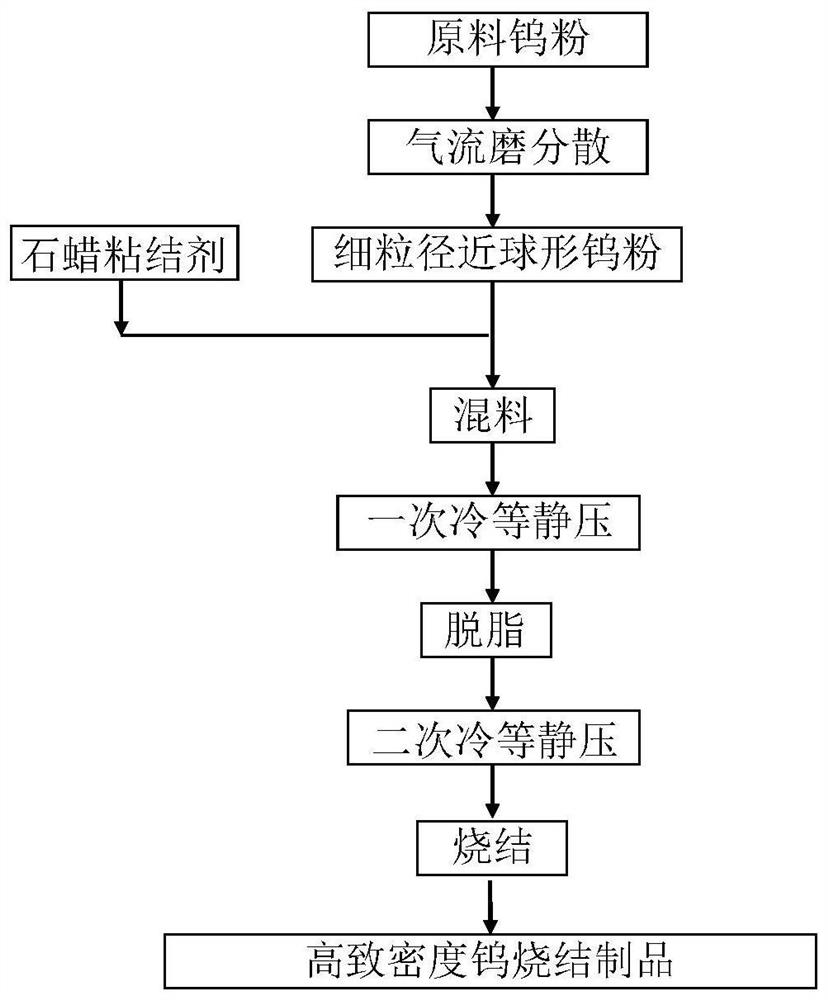

A method for preparing high-density tungsten sintered products

A sintered product and densification technology, applied in the field of powder metallurgy, can solve problems such as hindering the uniform densification of tungsten slabs, and achieve the effect of narrow grain size distribution, accelerated densification, and ensure uniformity and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

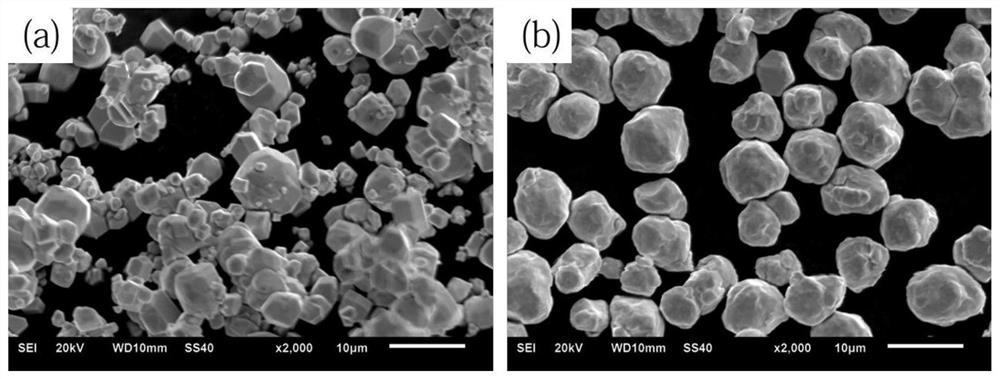

Embodiment 1

[0026] Using a counter-jet jet milling device, the raw material tungsten powder with particle size distribution (d10=1.1 μm, d50=4.8 μm, d90=15.3 μm) was subjected to two jet milling treatments. For the first jet mill, the pressure of the grinding chamber is set to 0.80MPa, and the frequency of the sorting wheel is 30Hz to realize the dispersion and crushing of powder. In the second jet mill, the pressure of the grinding chamber is set to 0.70MPa, and the frequency of the sorting wheel is 60Hz to make the powder surface smoother and further improve the fluidity of the powder. Both jet mills use nitrogen as the grinding medium, so that the oxygen content in the grinding chamber is ≤0.05%. Finally, jet-milled fine-grained tungsten powder is obtained, and the particle size distribution is (d10=1.3 μm, d50=1.9 μm, d90=2.8 μm). The fine-grained tungsten powder processed by the jet mill and the paraffin wax binder were mixed in a double planetary mixer at 110 ° C and a speed of 40 ...

Embodiment 2

[0028]Using a counter-jet jet milling device, the raw material tungsten powder with particle size distribution (d10=1.5 μm, d50=5.2 μm, d90=16.8 μm) was subjected to two jet milling treatments. For the first jet mill, the pressure of the grinding chamber is set to 0.78MPa, and the frequency of the sorting wheel is 25Hz to realize the dispersion and crushing of powder. The second jet mill sets the pressure of the grinding chamber to 0.68MPa, and the frequency of the sorting wheel to 55Hz to make the powder surface smoother and further improve the fluidity of the powder. Both jet mills use nitrogen as the grinding medium, so that the oxygen content in the grinding chamber is ≤0.05%. Finally, jet-milled fine-grained tungsten powder is obtained, and the particle size distribution is (d10=1.8 μm, d50=2.5 μm, d90=3.9 μm). The fine-grained tungsten powder processed by the jet mill and the paraffin wax binder were mixed in a double planetary mixer at 110 ° C and a speed of 40 rpm f...

Embodiment 3

[0030] Using a counter-jet jet milling device, the raw material tungsten powder with a particle size distribution of (d10=2.9 μm, d50=7.1 μm, d90=20.3 μm) was subjected to two jet milling treatments. For the first jet mill, the pressure of the grinding chamber is set to 0.75MPa, and the frequency of the sorting wheel is 20Hz to realize the dispersion and crushing of powder. The second jet mill sets the pressure of the grinding chamber to 0.70MPa and the frequency of the sorting wheel to 50Hz to make the powder surface smoother and further improve the fluidity of the powder. Both jet mills use nitrogen as the grinding medium, so that the oxygen content in the grinding chamber is ≤0.05%. Finally, jet-milled fine-grained tungsten powder is obtained, and the particle size distribution is (d10=3.4 μm, d50=4.4 μm, d90=5.9 μm). The fine-grained tungsten powder processed by the jet mill and the paraffin wax binder were mixed in a double planetary mixer at 130°C and a speed of 50 rpm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com