Preparation method of tantalum-silicon alloy sputtering target material

A sputtering target, tantalum-silicon technology, applied in the field of target preparation, can solve the problems of production technology monopoly, low density of tantalum-silicon alloy sputtering target, long process, etc., to save time cost and energy cost, The effect of uniform internal tissue structure and uniform densification degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

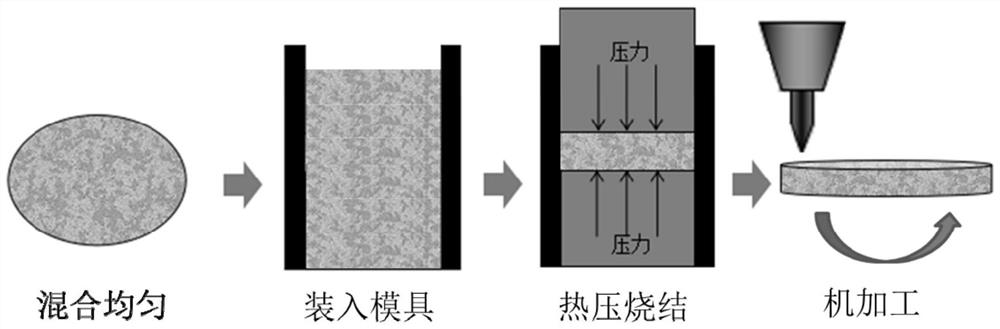

[0060] figure 1 A flowchart showing a method for preparing a tantalum-silicon alloy sputtering target provided by the present invention specifically includes the following steps:

[0061] (1) Mix tantalum powder and silicon powder evenly according to the mass ratio to obtain tantalum silicon powder;

[0062] (2) the tantalum silicon powder described in step (1) is packed into a mold and sealed;

[0063] (3) hot pressing and sintering the mold sealed in step (2) at 1130-1170° C. to obtain a crude tantalum-silicon alloy sputtering target;

[0064] (4) Machining the crude tantalum-silicon alloy sputtering target obtained in step (3) to obtain a tantalum-silicon alloy sputtering target.

[0065] For ease of understanding the present invention, the present invention enumerates embodiment as follows:

Embodiment 1

[0067] This embodiment provides a method for preparing a tantalum-silicon alloy sputtering target, the preparation method comprising the following steps:

[0068] (1) Mix tantalum powder with a particle size of <75 μm and silicon powder with a particle size of 3 to 5 μm in a powder mixer according to the mass ratio. The mixing adopts the method of dry mixing with silicon balls, and the quality of the balls is controlled. The ratio is 1:10, after 24h mixing evenly, tantalum silicon powder is obtained;

[0069] Wherein, the mass percentage of silicon in the mass ratio is 13.44%, and the rest is tantalum and unavoidable impurities;

[0070] (2) After loading the tantalum-silicon powder described in step (1) into the graphite mould, the tantalum-silicon alloy powder in the mold is firstly smoothed to ensure that the flatness is less than 5mm, and then compacted by manual column pressing , ensure the flatness <0.5mm, and then seal;

[0071] (3) Put the mold sealed in step (2) int...

Embodiment 2

[0075] This example provides a method for preparing a tantalum-silicon alloy sputtering target, except that the step (3) is replaced by one-time heating to the target temperature, and other conditions are exactly the same as in Example 1, and the details are as follows :

[0076] (3) Put the mold sealed in step (2) into a hot-press sintering furnace, evacuate to below 100Pa, then raise the temperature to 1150°C at a heating rate of 5°C / min and keep it warm for 2 hours, and finally heat it up at a temperature of 0.5MPa / min The pressurization rate is pressurized to 30MPa and the temperature is maintained for 2 hours; wherein, during the heating process of heating up to 900-1000°C and 1130-1170°C, it is necessary to control the internal pressure of the sealed mold to <6MPa;

[0077] After the heat preservation and pressure holding is completed, close the hot-press sintering furnace and cool it down, and then fill it with argon until the vacuum indication number is -0.07MPa. When ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com