A kind of wheel hub forging method

A hub forging and final forging technology, applied in the field of forging, can solve the problems of increased process time, raw material waste, and many process steps, and achieve the effects of reducing heating space, saving energy consumption, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

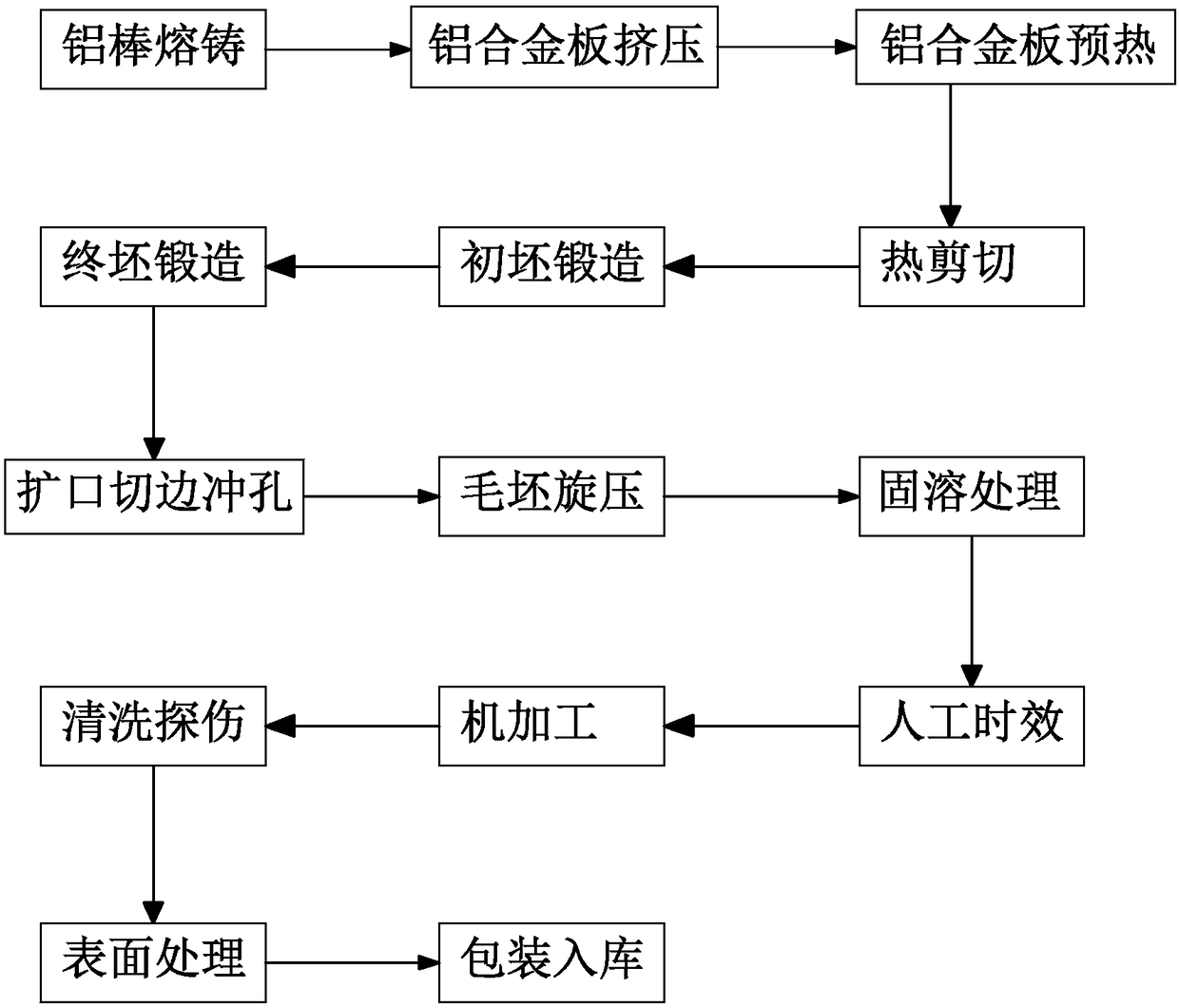

[0037] Embodiment 1, a kind of wheel hub forging method, see appendix figure 1 , which is mainly divided into several major steps of material preparation, forging, spinning, heat treatment and machining. Based on a 17-inch aluminum alloy wheel hub, the 7A04 aluminum alloy extruded plate with a thickness of 65mm is thermally cut to a size of 350mm ×350mm×65mm square blank;

[0038] The material preparation stage is a continuous production process in this embodiment, a. After the aluminum rod is melted and cast, an aluminum alloy plate of 350mm×65mm is extruded by an extruder; b. The extruded aluminum alloy plate is conveyed online into the preheating The furnace is heated to 440°C, and preheated for 30 minutes; c. One end of the preheated aluminum alloy plate coming out of the furnace is placed on the supporting mechanism, and the hydraulic cutter at the outlet of the furnace directly cuts the preheated aluminum alloy. On-line hot cutting, the cut billet will fall directly to ...

Embodiment 2

[0042] Embodiment 2, a kind of wheel hub forging method, refer to the attached figure 1, which is mainly divided into several major steps of material preparation, forging, spinning, heat treatment and machining. Based on a 17-inch aluminum alloy wheel hub, the 6061 aluminum alloy extruded plate with a thickness of 65mm is thermally cut to a size of 350mm. ×350mm×65mm square blank;

[0043] The material preparation stage is a continuous production process in this embodiment, a. After the aluminum rod is melted and cast, an aluminum alloy plate of 350mm×65mm is extruded by an extruder; b. The extruded aluminum alloy plate is conveyed online into the preheating The furnace is heated to 470°C, and preheated for 40 minutes; c. One end of the preheated aluminum alloy plate coming out of the furnace is placed on the supporting mechanism, and the hydraulic cutter at the exit of the furnace directly cuts the preheated aluminum alloy. On-line hot cutting, the cut billet will fall direc...

Embodiment 3

[0047] Embodiment 3, a kind of hub forging method, refer to the attached figure 1 , which is mainly divided into several major steps of material preparation, forging, spinning, heat treatment and machining. Based on a 17-inch aluminum alloy wheel hub, the 6061 aluminum alloy extruded plate with a thickness of 58mm is thermally cut to a size of 370mm ×370mm×58mm square blank;

[0048] The material preparation stage is a continuous production process in this embodiment, a. After the aluminum rod is melted and cast, an aluminum alloy plate of 370 mm × 58 mm is extruded by an extruder; b. The extruded aluminum alloy plate is conveyed online into the preheating The furnace is heated to 450°C, and preheated for 40 minutes; c. One end of the preheated aluminum alloy plate coming out of the furnace is placed on the supporting mechanism, and the hydraulic cutter at the exit of the furnace directly cuts the preheated aluminum alloy. On-line hot cutting, the cut billet will fall directl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com