Application of zeolite molecular sieve or modified zeolite molecular sieve in mosquito trapping and modifying method

A technology of zeolite molecular sieve and modified zeolite, which is applied in the field of killing mosquitoes, can solve the pollution of chemical synthesis agents and other problems, and achieve good application prospects, improved ability, and efficient mosquito killing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

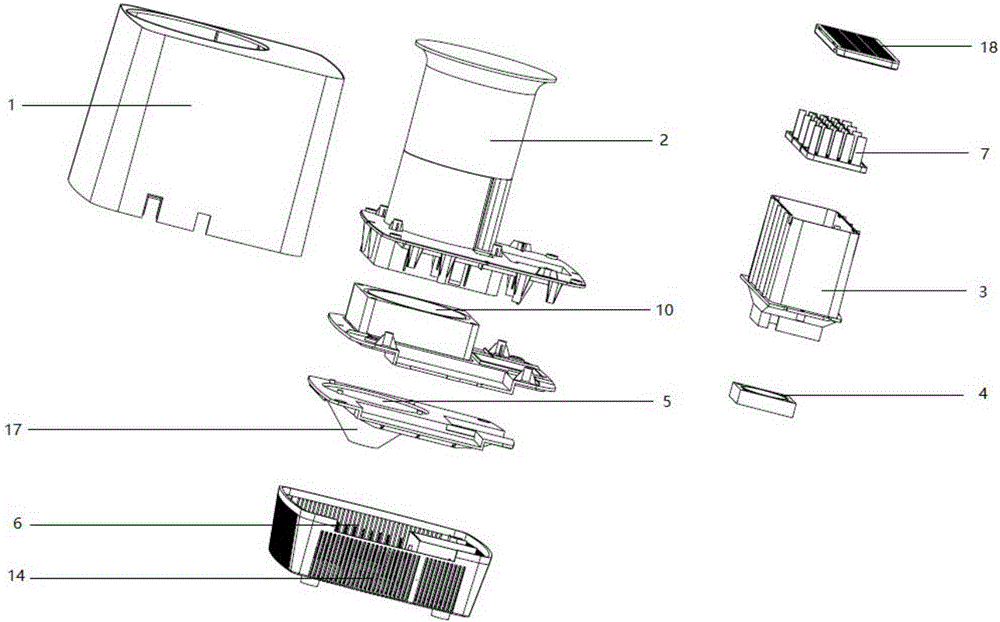

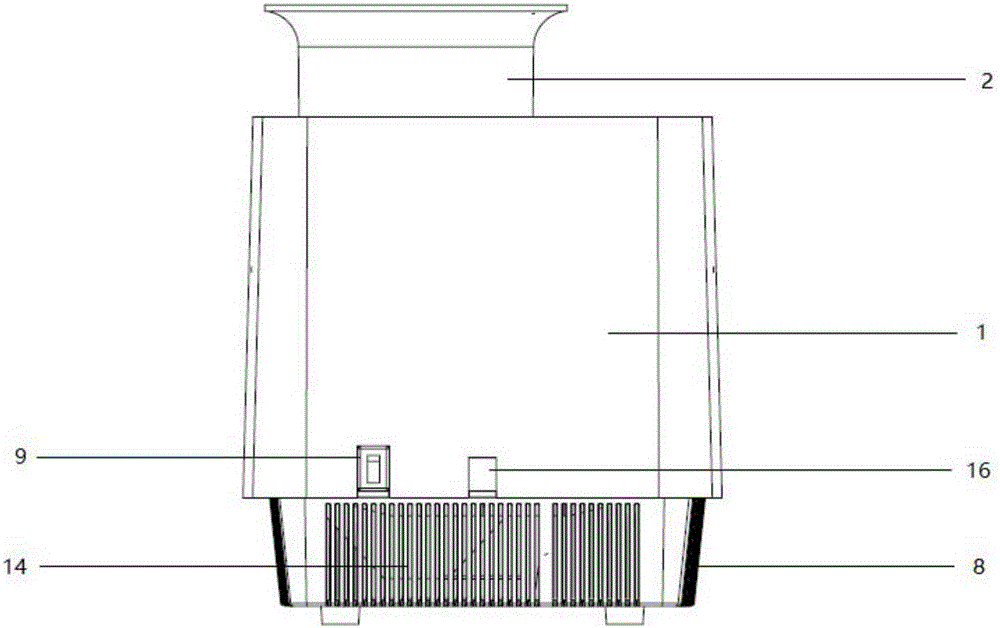

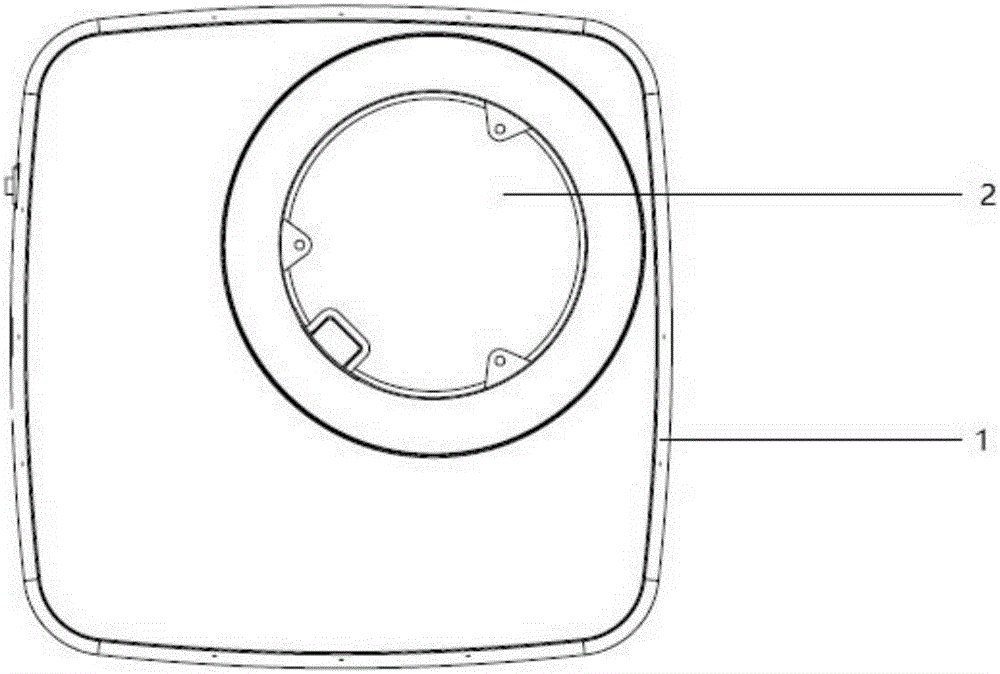

Image

Examples

Embodiment 1

[0074] Embodiment 1: Ethylenediamine modified 10X type zeolite molecular sieve

[0075] (1) 600g 10X type zeolite molecular sieves are loaded into the reactor, then feed helium at a speed of 200mL / min;

[0076] (2) Pass helium through a bubbler containing ethylenediamine at a rate of 200mL / min at room temperature, and pass helium saturated with ethylenediamine vapor into the reactor for 30 minutes;

[0077] (3) Helium was introduced at a rate of 200 mL / min for 12 hours to remove ethylenediamine weakly bound to the zeolite molecular sieve to obtain a modified zeolite molecular sieve.

Embodiment 2

[0078] Embodiment 2: Ethylenediamine modified 13X type zeolite molecular sieve

[0079] (1) 350g 13X type zeolite molecular sieves are packed in the reactor, then pass into helium with the speed of 300mL / min;

[0080] (2) At room temperature, pass helium through a bubbler containing ethylenediamine at a rate of 500mL / min, and pass helium saturated with ethylenediamine vapor into the reactor for 50min;

[0081] (3) Helium was introduced at a rate of 300 mL / min for 24 hours to remove ethylenediamine weakly bound to the zeolite molecular sieve to obtain a modified zeolite molecular sieve.

Embodiment 3

[0082] Embodiment 3: Ethylenediamine modified Y-type zeolite molecular sieve

[0083] (1) 200g Y type zeolite molecular sieves are packed in the reactor, then pass into helium with the speed of 150mL / min;

[0084] (2) At room temperature, pass helium through a bubbler containing ethylenediamine at a rate of 350mL / min, and pass helium saturated with ethylenediamine vapor into the reactor for 45min;

[0085] (3) Helium was introduced at a rate of 150 mL / min for 12 hours to remove ethylenediamine weakly bound to the zeolite molecular sieve to obtain a modified zeolite molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com