Comprehensive utilization method of mixed gas containing hydrogen fluoride and hydrogen chloride

A technology of mixed gas and hydrogen chloride, applied in chemical instruments and methods, preparation of amino compounds, preparation of organic compounds, etc., can solve the problems of low utilization rate of resources, large discharge of acidic wastewater, difficult treatment of fluorine-containing hydrochloric acid, etc. It has strong performance, high processing efficiency, and the effect of promoting energy saving, emission reduction and cleaner production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

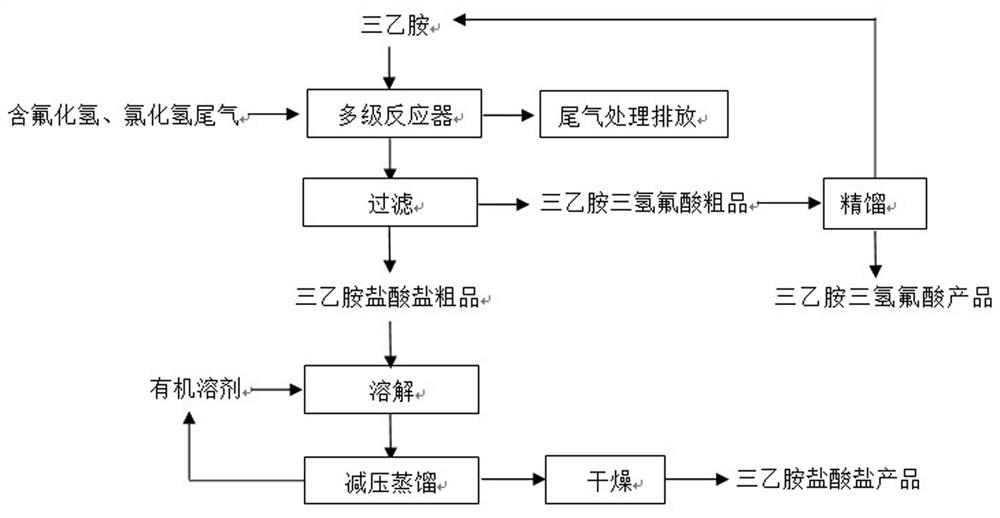

Method used

Image

Examples

Embodiment 1

[0027] A comprehensive utilization method of a mixed gas containing hydrogen fluoride and hydrogen chloride, said method specifically comprising the following steps:

[0028] 1) Gas absorption

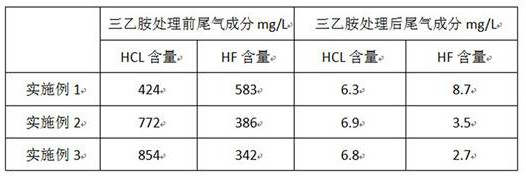

[0029] Nitrogen gas was introduced in advance to replace the air in the two-stage reactor system connected in series from head to tail, and the treatment time was 10 minutes. Then add triethylamine to the two reactors to 50% of the reactor volume; start stirring, so that the mixed tail gas containing hydrogen fluoride and hydrogen chloride is first passed into the primary reactor under the liquid level of triethylamine, and the reaction temperature is controlled at 10°C and the pressure -5KPa. The unabsorbed hydrogen fluoride and hydrogen chloride gas enter the next-stage reactor through the gas phase connecting pipeline for reaction;

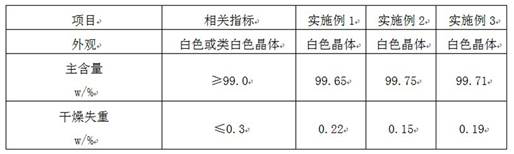

[0030] When the solid content in the primary reactor reached 20%, the reaction solution was discharged from the reactor feeding port and filtered, an...

Embodiment 2

[0037] A comprehensive utilization method of a mixed gas containing hydrogen fluoride and hydrogen chloride, said method specifically comprising the following steps:

[0038] 1) Gas absorption

[0039] Nitrogen gas was introduced in advance to replace the three-stage reactor system, and the treatment time was 20 minutes. Then add triethylamine to the three reactors to 60% of the reactor volume; start stirring, so that the mixed tail gas containing hydrogen fluoride and hydrogen chloride is first passed into the primary reactor under the liquid level of triethylamine, and the reaction temperature is controlled at 25 ° C, the pressure -2.5KPa. The unabsorbed hydrogen fluoride and hydrogen chloride gas enter the next-stage reactor step by step through the gas-phase connection pipeline for absorption reaction;

[0040] When the solid content in the first-stage reactor reaches 30%, the reaction solution is discharged from the reactor outlet and filtered, and the content of F in t...

Embodiment 3

[0047] 1) Gas absorption

[0048] The four-stage reactor system was replaced by argon gas in advance, and the treatment time was 30 minutes. Then add triethylamine to the four reactors to 75% of the reactor volume; start stirring, so that the mixed tail gas containing hydrogen fluoride and hydrogen chloride is first passed into the primary reactor under the liquid level of triethylamine, and the reaction temperature is controlled at 40 ° C. Pressure -1KPa. The unabsorbed hydrogen fluoride and hydrogen chloride gas enter the next-stage reactor step by step through the gas-phase connection pipeline for absorption reaction;

[0049] When the solid content in the first-stage reactor reaches 40%, the reaction solution is discharged from the feed port of the reactor and filtered, and the content of F in the filtrate is measured, and the solid paste obtained is the crude product of triethylamine hydrochloride. Then, the reaction liquid in the secondary reactor is poured into the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com