FGH sequence full-automatic vacuum heat conducting oil heating and dipping paint drying equipment and process thereof

A kind of drying equipment, fully automatic technology, applied in the direction of pretreatment surface, coating, surface coating liquid device, etc., can solve pollution, resource waste environment and other problems, achieve pollution reduction, uniform heating temperature, no temperature The effect of dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

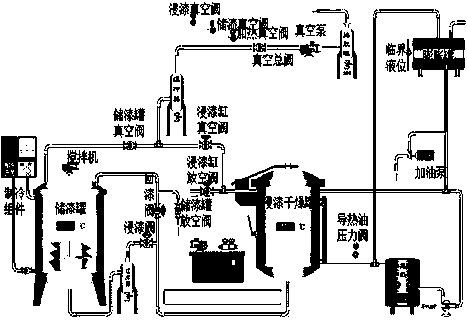

[0024] Such as figure 1 A FGH series full-automatic vacuum heat transfer oil heating dipping and drying equipment and its process are shown, including a refrigeration unit, a paint storage tank, a paint storage mixer, a filter, a paint storage tank vacuum valve, a paint dipping valve, and a paint return valve , paint storage tank vent valve, buffer paint vacuum valve, paint storage tank vacuum valve, heating vacuum valve, vacuum master valve, vacuum pump, discharge tank, paint vent valve, paint drying tank heat transfer oil heater, heat transfer oil pump, Expansion tank, refueling pump, the refrigerating unit is connected to the paint storage tank, the paint storage tank is connected to the vacuum valve of the paint storage tank through a pipeline, the vacuum valve of the paint storage tank is connected to a buffer through a pipeline, and the buffer is passed through The pipeline is connected to the vacuum main valve, the vacuum main valve is connected to the vacuum pump throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com