Granular round kidney-shaped green tea far-infrared fixation technology

A far-infrared greening and granulation technology, which is applied in the field of tea deep processing, can solve the problems that affect the aroma, soup color, taste, burnt flakes, burnt leaves, and tea stems that cannot be completely killed, so as to achieve clear color, green odor, and biological The effect of strong enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

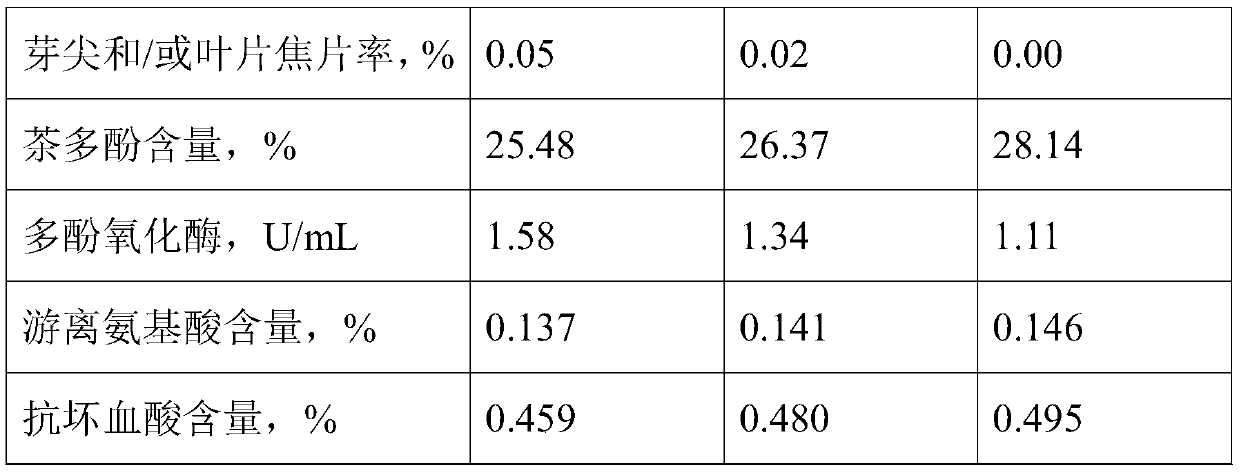

Examples

Embodiment 1

[0023] Granular round waist shape green tea far-infrared green-fixing process comprises the following steps:

[0024] S1. Pick fresh leaf raw materials containing one bud and one leaf, spread them evenly on the bamboo plaque, with a thickness of 0.5cm, and then wither at 25°C, with a withering humidity of 66%, and a withering time of 6 hours, and stir every 20 minutes withering once;

[0025] S2. Put the withered tea leaves into the kneading machine and roll them back and forth until the tea leaves are lightly gripped into a ball, and then loosen after light pressing. During the rolling process, the temperature is controlled at 70°C, and then the tea leaves are dispersed and wrapped repeatedly in the same direction to form Granular round waist-shaped tea leaves with the bud as the core and the leaf wrapping the tip of the bud;

[0026] S3. Send the granular round waist-shaped tea leaves into the drum fixing machine equipped with a far-infrared heater, raise the temperature fr...

Embodiment 2

[0028] Granular round waist shape green tea far-infrared green-fixing process comprises the following steps:

[0029] S1. Pick fresh leaf raw materials containing one bud and one leaf, spread them evenly on the bamboo plaque, with a thickness of 1.5cm, and then wither at 20°C, with a withering humidity of 70%, and a withering time of 4 hours, and stir every 30 minutes withering once;

[0030] S2. Put the withered tea leaves into the kneading machine and roll them back and forth until the tea leaves are lightly gripped into a ball, and then loosen after light pressing. During the rolling process, the temperature is controlled at 60°C, and then the tea leaves are dispersed and wrapped repeatedly in the same direction to form Granular round waist-shaped tea leaves with the bud as the core and the leaf wrapping the tip of the bud;

[0031] S3. Send the granular round waist-shaped tea leaves into the drum fixing machine equipped with a far-infrared heater, raise the temperature fr...

Embodiment 3

[0033] Granular round waist shape green tea far-infrared green-fixing process comprises the following steps:

[0034] S1. Pick fresh leaf raw materials containing one bud and one leaf, spread them evenly on the bamboo plaque, with a thickness of 0.6cm, and then wither at 24°C, with a withering humidity of 67%, and a withering time of 5.5h, wherein each withering is 22min Flip once;

[0035] S2. Put the withered tea leaves into the kneading machine and roll them back and forth until the tea leaves are lightly gripped into a ball, and then loosen after light pressing. During the rolling process, the temperature is controlled at 68°C, and then the tea leaves are dispersed and wrapped repeatedly in the same direction to form Granular round waist-shaped tea leaves with the bud as the core and the leaf wrapping the tip of the bud;

[0036] S3. Send the granular round waist-shaped tea leaves into the drum fixing machine equipped with a far-infrared heater, raise the temperature from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com