Long-acting antibacterial silicone rubber and preparation method thereof

A silicone rubber and long-acting technology, which is applied in the field of long-acting antibacterial silicone rubber and its preparation, can solve the problems of difficult to balance biocompatibility and long-acting antibacterial properties, and achieve strong binding force, stable chemical structure, and good application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] As another aspect of the present invention, the present invention provides a kind of preparation method of long-acting antibacterial silicone rubber, comprising the steps:

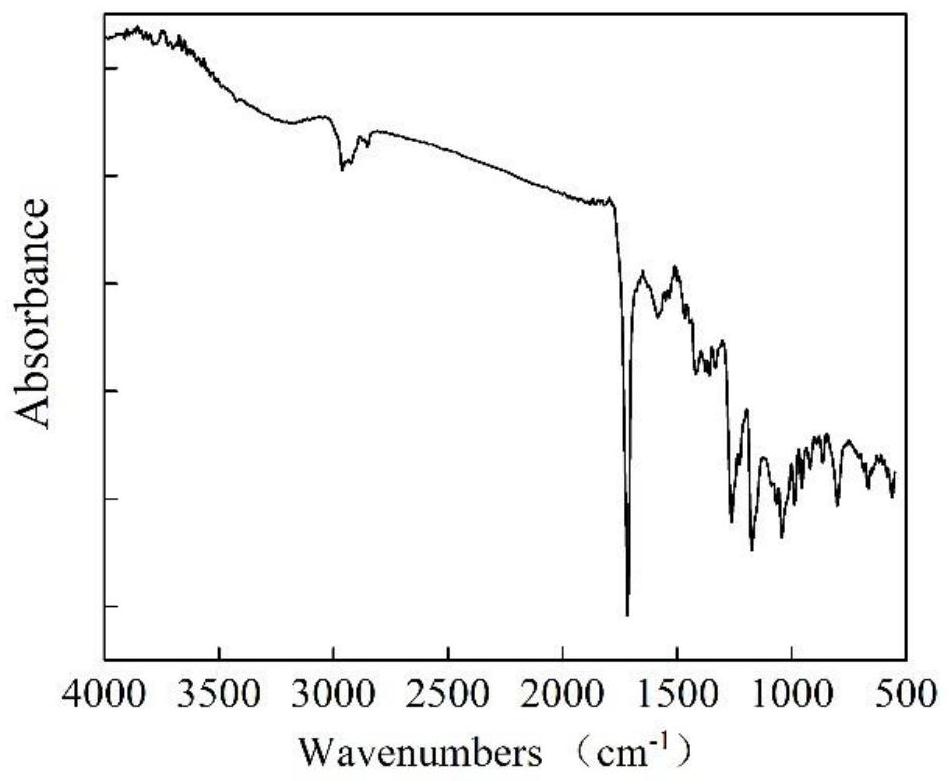

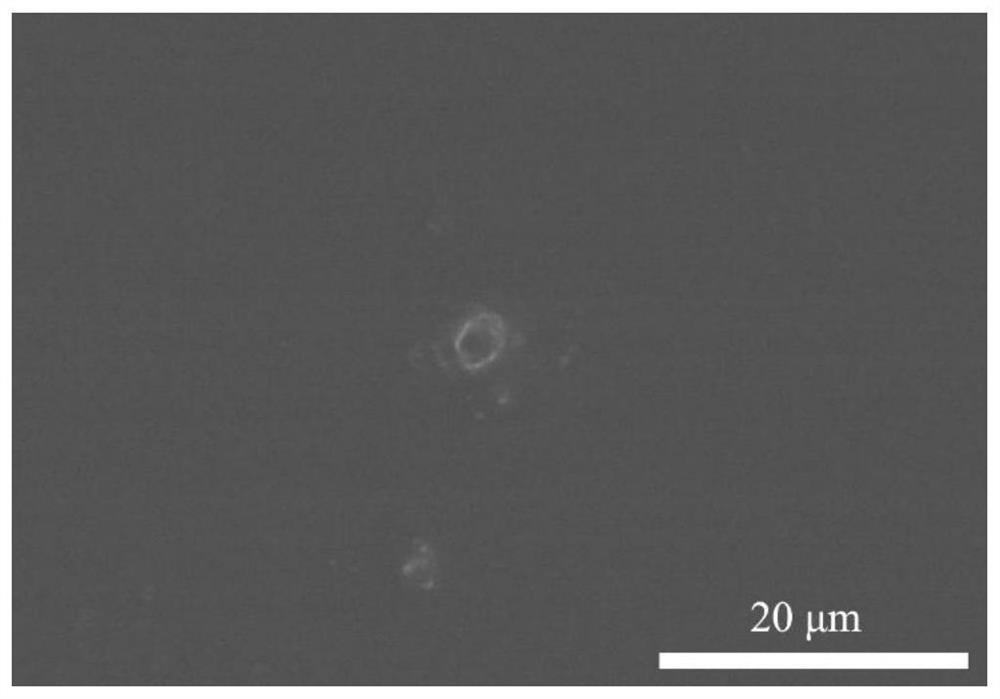

[0065] S1. Soak the silicone rubber in one or more composite alcohol solutions containing 5%-20% vinyl silane coupling agent or methacryloxysilane coupling agent for 2-24 hours ( The reaction temperature is 30-60°C, 3cm 2 Silicone rubber plus 1mL reaction solution), ultrasonic cleaning after the reaction to obtain modified silicone rubber;

[0066] S2. Prepare a mixed aqueous solution containing imidazolium salt, initiator and polyvinyl or allyl compound, the concentration of imidazolium salt in the mixed aqueous solution is 0.2-2g / mL, and the mass of initiator is 0.01%-2% of the mass of imidazolium salt , the polyvinyl or allyl compound is 1%-10% of the imidazolium salt mole fraction;

[0067] S3. Soak the modified silicone rubber in S1 in the mixed aqueous solution in S2, and react under trigger...

Embodiment 1

[0089] A preparation method of long-acting antibacterial silicone rubber, comprising the steps of:

[0090] S1. Put the silicone rubber into the mixed solution of sulfuric acid and hydrogen peroxide (7:3 by volume), soak for 1 minute, take out the silicone rubber, wash and dry it, then soak the silicone rubber in a solution containing 15% γ-methacrylic acid In an ethanol solution of acyloxypropyltriethoxysilane, react at 50°C for 18 hours, take out the silicone rubber, ultrasonically clean it and dry it to obtain a modified silicone rubber;

[0091] S2. Dissolving 1-allyl-3-butylimidazolium tetrafluoroborate, azobisisobutamidine hydrochloride, and 1,3-propanediol diacrylate in deionized water respectively, and preparing a functional reaction solution, The concentration of 1-allyl-3-butylimidazole tetrafluoroborate in aqueous solution is 1.3g / mL, and the mass of azobisisobutyramide hydrochloride is 1-allyl-3-butylimidazole 0.5% of the quality of tetrafluoroborate, 1,3-propaned...

Embodiment 2

[0094] A preparation method of long-acting antibacterial silicone rubber, comprising the steps of:

[0095] S1. Soak the silicone rubber in an ethanol solution containing 20% vinyl tris(2-methoxyethoxy)silane, react at 30° C. for 24 hours, take out the silicone rubber and ultrasonically clean it and dry it to obtain a modified silicone rubber;

[0096] S2. Dissolve 1-vinyl-3-ethylimidazolium chloride salt, potassium persulfate, and N,N-methylenebisacrylamide in deionized water in sequence to configure a functional reaction solution. 1-vinyl-3-ethyl The mass concentration of imidazolium chloride salt in aqueous solution is 1.2g / mL, the mass of potassium persulfate is 0.01% of the mass of 1-vinyl-3-ethylimidazolium chloride salt, and the molar amount of N,N-methylenebisacrylamide The number is 8% of the moles of 1-vinyl-3-ethylimidazolium chloride salt;

[0097] S3. Soak the silicone rubber in S1 in the functional reaction solution of S2, irradiate with ultraviolet light, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com