Nickel nanofiber membrane for membrane catalysis and preparation method of nickel nanofiber membrane

A nanofiber membrane and nanofiber technology, which is applied in chemical instruments and methods, fiber types, fiber treatment, etc., can solve the problem of high activity, high-efficiency catalytic function and macro-preparation of supported nickel-based catalysts, and reduce the number of NiB particles. and effective catalytic area, the complex use process of supported catalysts, etc., to achieve the effect of easy to realize large-scale preparation, difficult to improve catalytic efficiency, and improve catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing a nickel nanofiber membrane for membrane catalysis, comprising the following steps:

[0036] 1) Mix 0.2kg of thermoplastic polymer PVA-co-PE and 3.8kg of cellulose acetate butyrate uniformly, extrude and granulate in a twin-screw extruder with a processing temperature of 170°C to prepare PVA -co-PE / cellulose acetate butyrate composite.

[0037] 2) drawing the PVA-co-PE / cellulose acetate butyrate composite material obtained through step 1) through a melt spinning machine, and spinning to obtain a composite fiber;

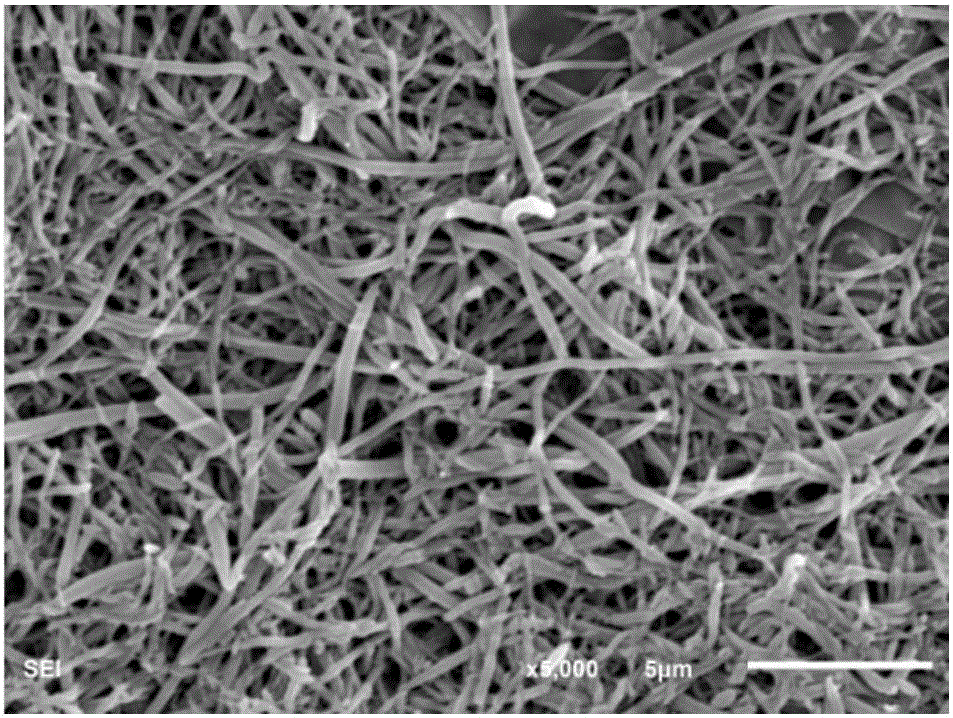

[0038] 3) Reflux the composite fiber in acetone at 60°C for 72 hours to extract cellulose acetate butyrate, dry the composite fiber after extraction at room temperature, and prepare PVA-co-PE nanofibers with an average diameter of 50nm .

[0039] 4) Get 0.5g of PVA-co-PE nanofibers and disperse them in 500ml of ethanol to form a nanofiber dispersion, and then coat the nanofiber dispersion on the surface of a smooth plastic film or glas...

Embodiment 2

[0049] A method for preparing a nickel nanofiber membrane for membrane catalysis, comprising the following steps:

[0050] 1) 0.5kg of thermoplastic polymer PVA-co-PE is uniformly mixed with 4kg of cellulose acetate butyrate, extruded and granulated in a twin-screw extruder with a processing temperature of 170°C to prepare PVA- co-PE / cellulose acetate butyrate composite.

[0051] 2) drawing the PVA-co-PE / cellulose acetate butyrate composite material obtained through step 1) through a melt spinning machine, and spinning to obtain a composite fiber;

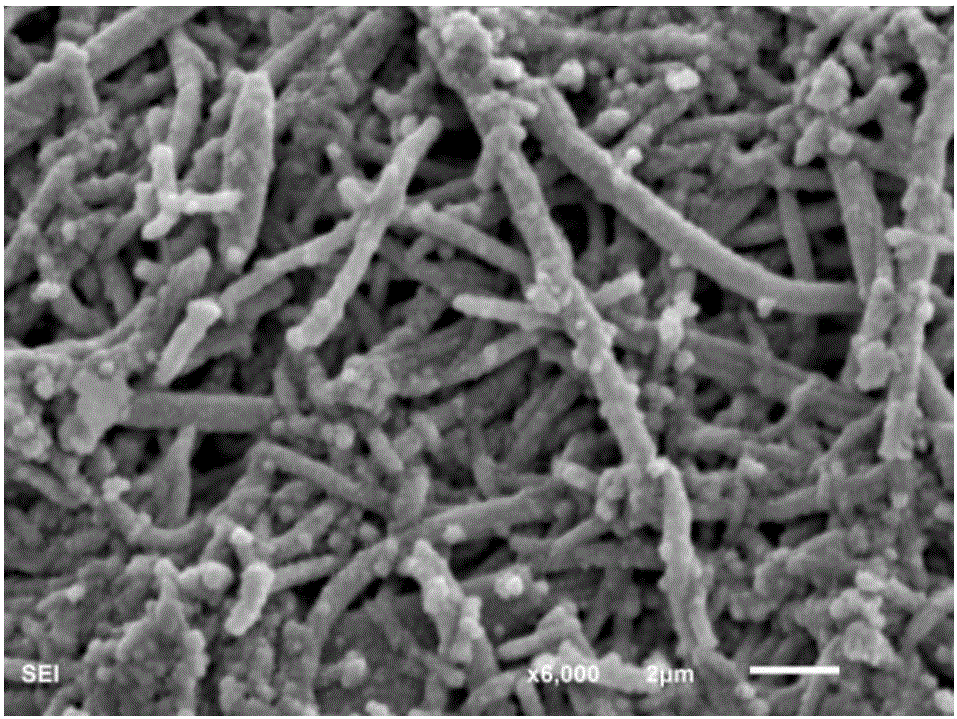

[0052] 3) Reflux the composite fiber in acetone at 60°C for 72 hours to extract cellulose acetate butyrate, dry the composite fiber after extracting cellulose acetate butyrate at room temperature, and prepare PVA-co-PE nanofibers with an average diameter of 100nm .

[0053] 4) Get the PVA-co-PE nanofiber of 0.7g and be dispersed in the ethanol of 700ml, form nanofiber dispersion liquid, then nanofiber dispersion liquid is coated ...

Embodiment 3

[0063] A method for preparing a nickel nanofiber membrane for membrane catalysis, comprising the following steps:

[0064] 1) Mix 1kg of thermoplastic polymer PVA-co-PE and 4kg of cellulose acetate butyrate evenly, extrude and granulate in a twin-screw extruder with a processing temperature of 170°C to prepare PVA-co -PE / cellulose acetate butyrate composite.

[0065] 2) Drawing and spinning the PVA-co-PE / cellulose acetate butyrate composite material obtained in step 1) through a melt spinning machine to obtain composite fibers.

[0066] 3) Reflux the composite fiber in acetone at 60°C for 72 hours to extract cellulose acetate butyrate, dry the composite fiber after extracting cellulose acetate butyrate at room temperature, and prepare PVA-co-PE nanofibers with an average diameter of 200nm .

[0067] 4) Get the PVA-co-PE nanofiber of 0.5g and disperse it in the ethanol of 500ml, form the nanofiber dispersion liquid, then the nanofiber dispersion liquid is coated on smooth pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com