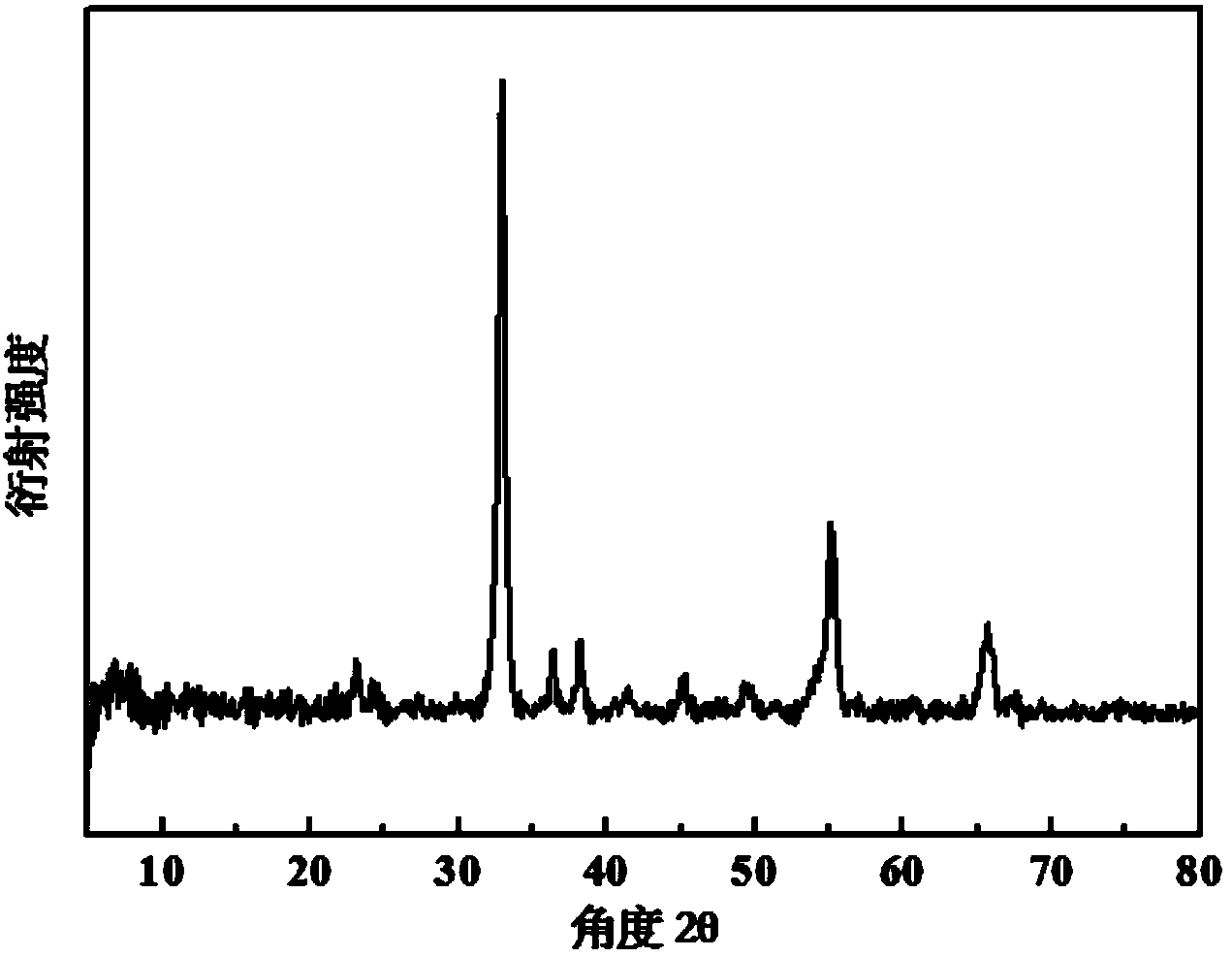

Preparation method of core-shell structure vanadium trioxide microspheres

A technology of vanadium trioxide microspheres and core-shell structure, which is applied in the direction of vanadium oxide, chemical instruments and methods, and structural parts, and can solve problems such as uneven shape and size, small specific surface area of products, and poor safety, and achieve shape and size Uniformity, low price, high abundance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Specific embodiment one: the preparation method of the core-shell structure vanadium trioxide microspheres of this embodiment is carried out according to the following steps:

[0022] 1. Add ammonium metavanadate into the solvent under the condition of 30℃~70℃, and prepare a solution with a concentration of 0.20~0.40mol / L;

[0023] 2. Add the solution obtained in step 1 into a high-pressure reactor, keep it warm at 180°C to 220°C for 8 to 15 hours, and then cool to room temperature;

[0024] 3. Centrifuge the cooled turbid liquid in step 2 at 3000-4000r / min for 2-5min, separate and collect the solid product, wash the obtained solid product with absolute ethanol for 2-3 times, then put the washed solid product into vacuum drying In the box, dry at 30℃~70℃ for 10~24h;

[0025] 4. Calcining the dried sample obtained in step 3 at 500° C. to 700° C. for 2 to 5 hours under nitrogen protection, and cooling to room temperature to obtain vanadium trioxide microspheres with a co...

specific Embodiment approach 2

[0029] Embodiment 2: This embodiment is different from Embodiment 1 in that the solvent described in step 1 is ethylene glycol, 1,3-propanediol or glycerol. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: under the condition of 30 ℃ described in step one, ammonium metavanadate is added in ethylene glycol, and the concentration is 0.20mol / L solution. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com