Method for preparing fluorine-contained multi-function epoxy resin

An epoxy resin, multi-functional technology, applied in the field of preparation of fluorine-containing multi-functional epoxy resin, to achieve the effects of environmental friendliness, good product quality, and easy recovery of solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

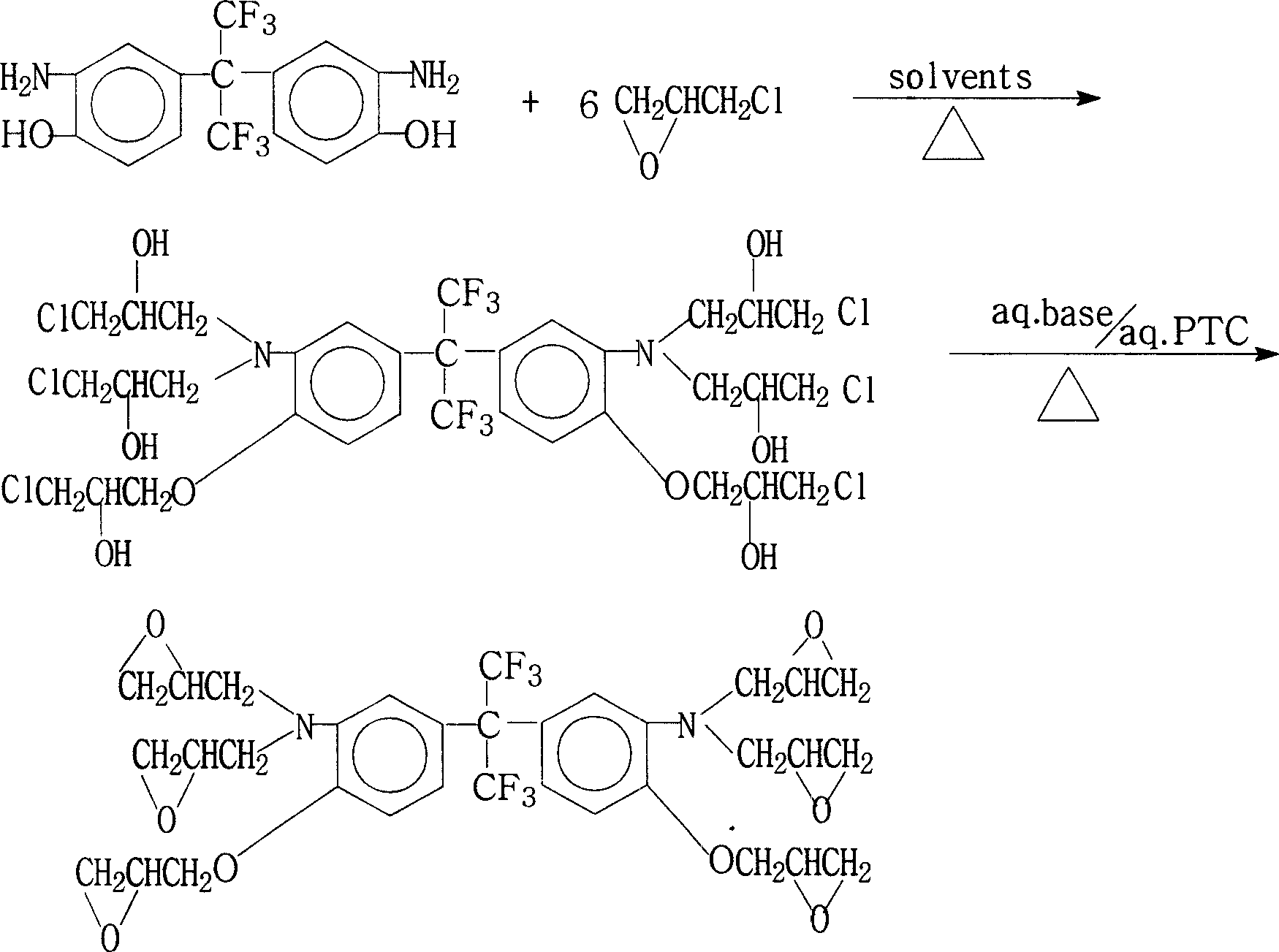

Method used

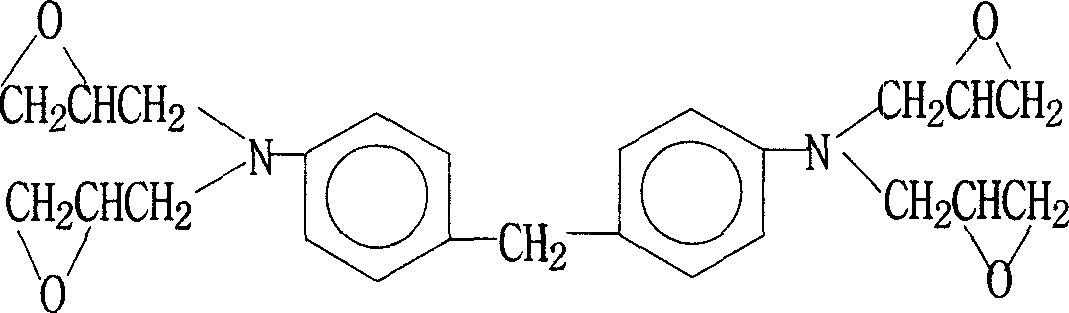

Image

Examples

Embodiment 1

[0027] 36.6 grams (0.1 moles) of 2,2-bis(3-amino-4-hydroxyphenyl)-1,1,1,3,3,3-hexafluoropropane (BAHPFP), 55.5 grams (0.6 moles) of cyclo Add oxychloropropane (ECH), 1.8 ml of water and 18 ml of methyl isobutyl ketone (MIBK) into the reaction flask, stir and react at 40°C for 1 hour, heat up, react at 60°C for 1 hour, and then increase the reaction temperature Temperature, react at 80°C for 7 hours, and react at 90°C for 0.5 hours, cool the reaction solution to below 70°C, and add a 50% trimethyl (2-chloroethyl) ammonium chloride phase transfer catalyst aqueous solution at one time 6.0 g, stir quickly, add dropwise 80 g (0.8 moles) of 40% aqueous sodium hydroxide solution, after dropping within 1 hour, react at 50°C for 2 hours, heat up to 80°C and continue the reaction for 2 hours, add 100 ml of water and 150 milliliters of methyl isobutyl ketone (MIBK), after stirring evenly, leave standstill, liquid separation, remove water phase, stay and get organic phase mother liquor, w...

Embodiment 2

[0029] 36.6 grams (0.1 moles) of 2,2-bis(3-amino-4-hydroxyphenyl)-1,1,1,3,3,3-hexafluoropropane (BAHPFP), 185.0 grams (2.0 moles) of cyclo Add oxychloropropane (ECH), 3.6 ml of water and 18 ml of methyl isobutyl ketone (MIBK) into the reaction flask, stir and react at 40°C for 1 hour, heat up, react at 60°C for 5 hours, and then increase the reaction temperature temperature, after reacting for 2 hours at 90°C, cool the reaction solution to below 70°C, add 6.0 grams of trimethyl (2-chloroethyl) ammonium chloride phase transfer catalyst aqueous solution with a concentration of 50%, stir rapidly, and drop Add 100 grams (1.0 moles) of 40% sodium hydroxide aqueous solution, after dripping within 1 hour, react at 50°C for 2 hours, heat up to 80°C for 1 hour, continue to react at 90°C for 1 hour, add 100 ml of water and 150 milliliters of methyl isobutyl ketone (MIBK), after stirring evenly, leave standstill, liquid separation, remove water phase, stay and get organic phase mother li...

Embodiment 3

[0031]36.6 grams (0.1 moles) of 2,2-bis(3-amino-4-hydroxyphenyl)-1,1,1,3,3,3-hexafluoropropane (BAHPFP), 185.0 grams (2.0 moles) of cyclo Add oxychloropropane (ECH), 3.6 ml of water and 18 ml of toluene into the reaction flask, stir and react at 40°C for 1 hour, heat up, react at 60°C for 4 hours, then increase the reaction temperature, and react at 90°C for 1 hour Afterwards, cooling reaction solution to below 70 ℃, one-time addition concentration is 6.0 grams of trimethyl (2-chloroethyl) ammonium bromide phase-transfer catalyst aqueous solution of 50%, stir rapidly, drip 120 grams (1.2 mole) 40 % concentration of sodium hydroxide aqueous solution, after dripping within 1 hour, react at 50°C for 2 hours, heat up to 80°C for 1 hour, continue to react at 90°C for 1 hour, add 100 ml of water and 300 ml of toluene, and stir evenly , stand still, separate liquid, remove water phase, retain organic phase mother liquid, wash with water, stand still, separate liquid, organic mother l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com