Centrifugation water treatment method and device

A water treatment equipment and water treatment technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve problems such as unfavorable natural circulation, normal circulation of natural environment, algae cannot be eliminated by increasing oxygen, and affecting human living environment, etc. The effect of water eutrophication, simple structure and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

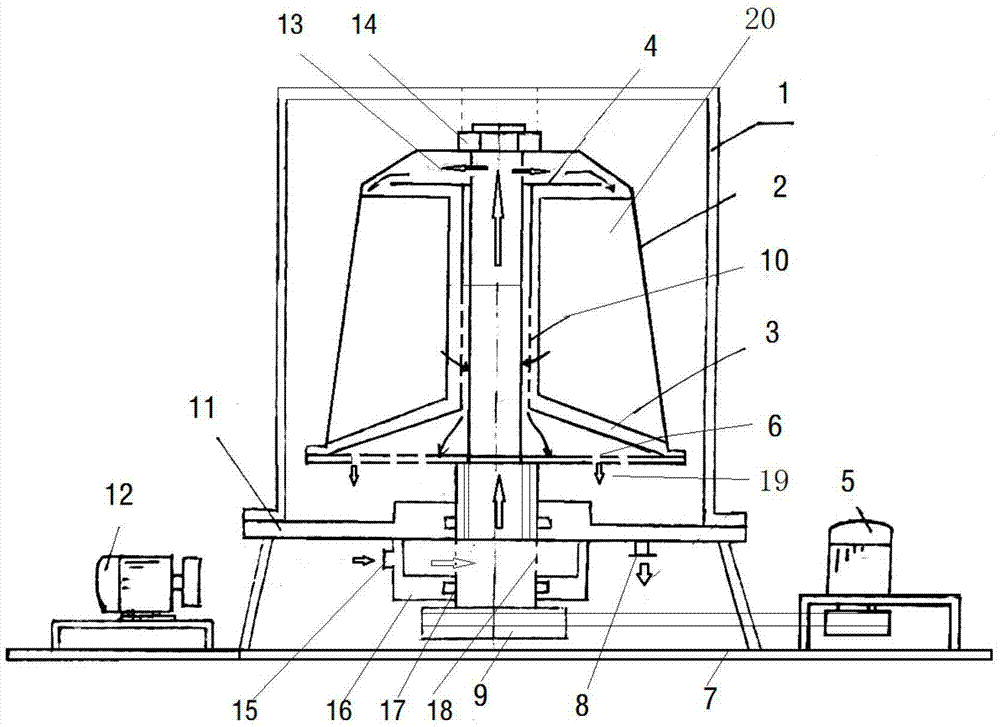

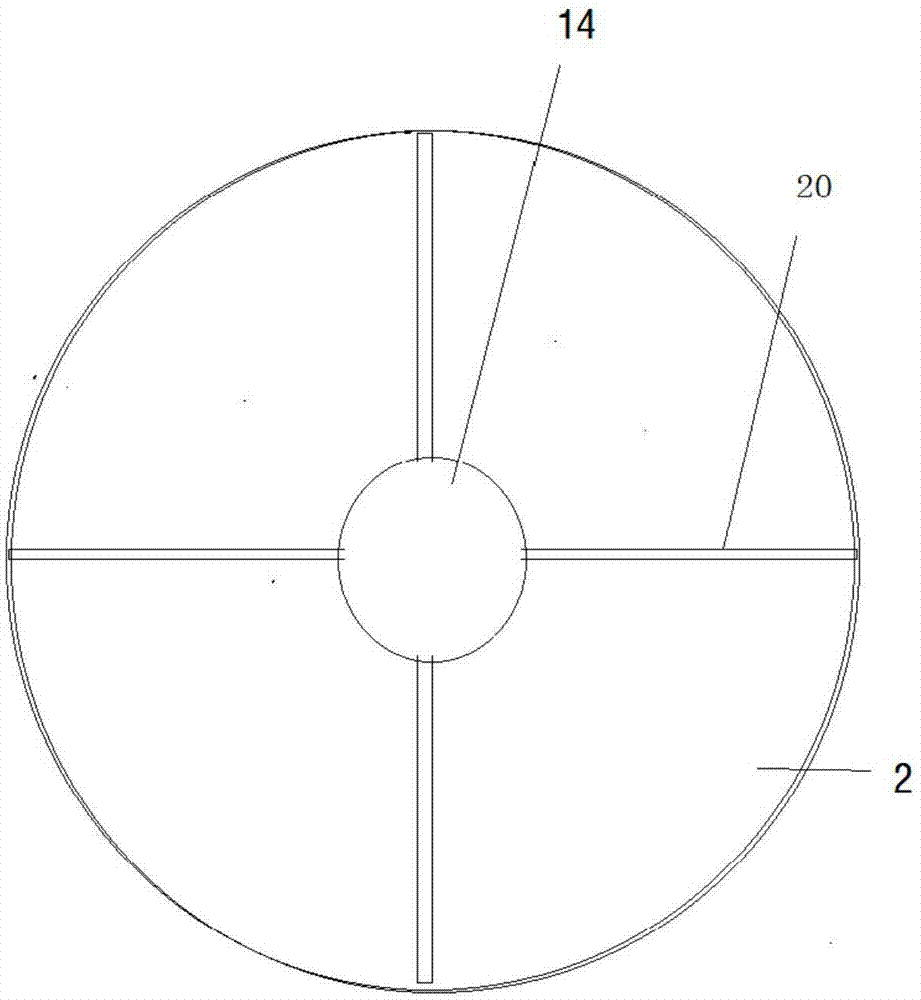

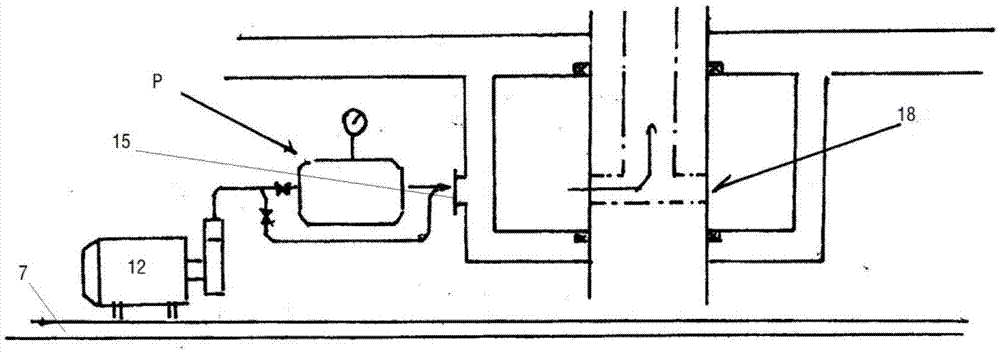

[0017] As shown in the figure, 1, the casing 2, the centrifugal drum 3, the isolation cover 4, the water distributor (distributor) 5, the drive motor 6, the bottom plate of the centrifugal drum 7, the machine base (installation bottom plate) 8, the outer casing Water outlet hole (drainage hole) 9, water inlet drive plate 10, centrifugal drum core filter screen 11, housing base 12, water pump and motor 13, water inlet shaft outlet hole 14, fixed nut 15, water pump inlet 16, water inlet Case (water storage tank) 17, water inlet drive shaft 18, drive shaft water inlet hole 19, water outlet hole (can be the water outlet recoil device) 20, partition blade on the drum is the partition plate; P is the pressure gauge of the water storage tank.

[0018] The water pumped by the water pump pressurizes into the water storage tank, and enters the centrifugal separator through the water holes distributed on the power inlet shaft. Through the water inlet 15, the water inlet shaft 17, the wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com