Gradient doped AZO thin film preparation method and application thereof

A gradient doping and thin film technology, applied in the field of solar cells, can solve the problem of uneven longitudinal distribution of electrical conductivity of the AZO electron transport layer, and achieve the effect of reducing the probability of carrier recombination, the method is simple and feasible, and the process of industrialization is accelerated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

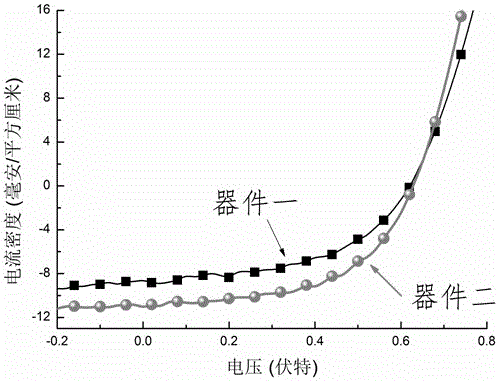

Image

Examples

Embodiment 1

[0028] A preparation method of gradient doped AZO film, said preparation method comprising the following steps:

[0029] a) Weigh 1 gram of zinc acetate dihydrate and 0.01-0.1 gram of aluminum nitrate nonahydrate and dissolve them in 10 ml of ethanol solution; add 0.1 ml of monoethanolamine into the solution to prepare Al-Zn atomic ratios of 0.1at% precursor solution A, 0.6at% precursor solution B and 1.1at% precursor solution C, stir the prepared solution at 20°C for 0.1h, age at room temperature for 24h, and set aside;

[0030] b) Spin-coat the precursor solution A on the cleaned and dried ITO glass substrate, the speed of the homogenizer is 2000rpm, the spin-coating time is 10s, and heat on a hot plate at 200°C for 30min to obtain AZO film 1; AZO film One has a thickness of 5 nm;

[0031] Precursor solution B is spin-coated on AZO film 1, and the preparation method of AZO film 1 is repeated, and AZO film 2 is prepared; Precursor solution C is dropped on the surface of AZO ...

Embodiment 2

[0035] A preparation method of gradient doped AZO film, said preparation method comprising the following steps:

[0036] a) Weigh 2 grams of zinc acetate dihydrate and 0.01-0.1 grams of aluminum nitrate nonahydrate and dissolve them in 20 milliliters of ethanol solution; take 0.2 milliliters of monoethanolamine and add it to the solution to prepare Al-Zn atomic ratios of 0.2at% precursor solution A, 0.7at% precursor solution B and 1.2at% precursor solution C, stir the prepared solution at 50°C for 0.5h, age at room temperature for 24h, and set aside;

[0037] b) The ITO glass substrate is immersed in the adhesion promoting solution and treated with ultrasonic for 50 minutes; then taken out and added with acetone for ultrasonic treatment for 20 minutes, rinsed with deionized water after taken out, and then dried with nitrogen gas;

[0038] The adhesion promoting liquid is composed of the following raw materials in parts by weight: 12 parts of hydroxyethyl cellulose, 25 parts of...

Embodiment 3

[0045] A preparation method of gradient doped AZO film, said preparation method comprising the following steps:

[0046] a) Weigh 3 grams of zinc acetate dihydrate and 0.01-0.1 grams of aluminum nitrate nonahydrate and dissolve them in 30 milliliters of ethanol solution; add 0.5 milliliters of monoethanolamine to the solution to prepare Al-Zn atomic ratios of 0.5at% precursor solution A, 1.0at% precursor solution B and 1.5at% precursor solution C, stir the prepared solution at 80°C for 1h, age at room temperature for 24h, and set aside;

[0047] b) The ITO glass substrate is immersed in the adhesion promoting solution, and ultrasonically treated for 60 minutes; then taken out and added with acetone and ultrasonically treated for 30 minutes, rinsed with deionized water after taking out, and then dried with nitrogen gas;

[0048] The adhesion promoting liquid is composed of the following raw materials in parts by weight: 15 parts of hydroxyethyl cellulose, 35 parts of methyl ort...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com