Textured transparent conductive thin film with periodic structure and preparation method thereof

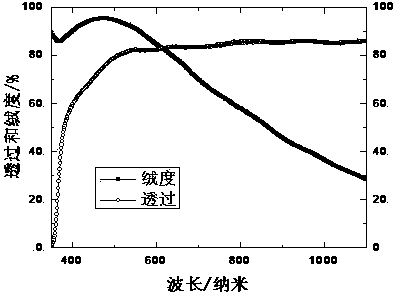

A technology of transparent conductive film and periodic structure, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of large feature size and roughness, increase battery cost, etc., achieve good scattering effect, increase optical path, and good trapping. light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

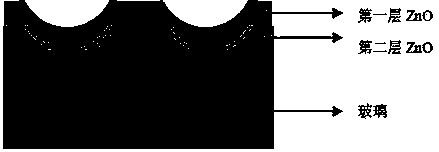

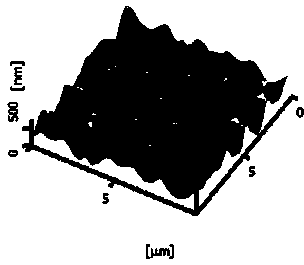

[0023] A periodic textured textured transparent conductive film, such as figure 1 As shown, it includes the substrate layer, the first layer of ZnO film that acts as a template, and the second layer of ZnO film that acts as a modification to form a laminated structure in turn. The substrate layer is hard substrate glass, and the ZnO film is doped zinc oxide n Type semiconductor material ZnO:H, in which the thickness of the first layer of ZnO film is 800nm, and the thickness of the second layer of ZnO film is 400nm, forming a textured transparent conductive film with a periodic structure with wide-spectrum scattering, and the periodic structure of ZnO The root mean square roughness of the surface transparent conductive film is 80 nm.

[0024] A kind of preparation method of the suede transparent conductive film of described periodic structure utilizes water bath method to assemble PS microsphere, uses O 2 Plasma etching PS microspheres, using the template effect of PS microsph...

Embodiment 2

[0034] A periodic textured textured transparent conductive film, such as figure 1 As shown, it includes the substrate layer, the first layer of ZnO film that acts as a template, and the second layer of ZnO film that acts as a modification to form a laminated structure in turn. The substrate layer is hard substrate glass, and the ZnO film is doped zinc oxide n Type semiconductor material ZnO: Al(AZO) film, in which the thickness of the first layer of ZnO film is 700nm, and the thickness of the second layer of ZnO film is 400nm, which constitutes a textured transparent conductive film with a periodic structure of wide-spectrum scattering. The root mean square roughness of the textured ZnO textured transparent conductive film is 85 nm.

[0035] A kind of preparation method of the suede transparent conductive film of described periodic structure utilizes water bath method to assemble PS microsphere, uses O 2 Plasma etching PS microspheres, using the template effect of PS microsph...

Embodiment 3

[0043] A periodic textured textured transparent conductive film, such as figure 1 As shown, it includes the substrate layer, the first layer of ZnO film that acts as a template, and the second layer of ZnO film that acts as a modification to form a laminated structure in turn. The substrate layer is hard substrate glass, and the ZnO film is doped zinc oxide n Type semiconductor material ZnO: H (HZO) thin film, in which the thickness of the first layer of ZnO thin film is 900nm, the thickness of the second layer of ZnO thin film is 400nm, which constitutes a textured transparent conductive thin film with a periodic structure of broad-spectrum scattering, periodic The root mean square roughness of the structured ZnO textured transparent conductive film is 120 nm.

[0044] A kind of preparation method of the suede transparent conductive film of described periodic structure utilizes water bath method to assemble PS microsphere, uses O 2 Plasma etching PS microspheres, using the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Root mean square roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com