Reflex-type screen

A reflective screen and light reflection technology, applied in the field of reflective screens, can solve problems such as complex manufacturing process, difficulty in increasing screen size, increased scattering on the surface of bright reflective layers, etc., and achieve the effect of improving contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described below according to preferred implementations. The purpose of these preferred embodiments is not to limit the scope of the present invention, but to illustrate the present invention. All the features of the present invention described in the embodiments and combinations thereof are not necessarily essential to the present invention.

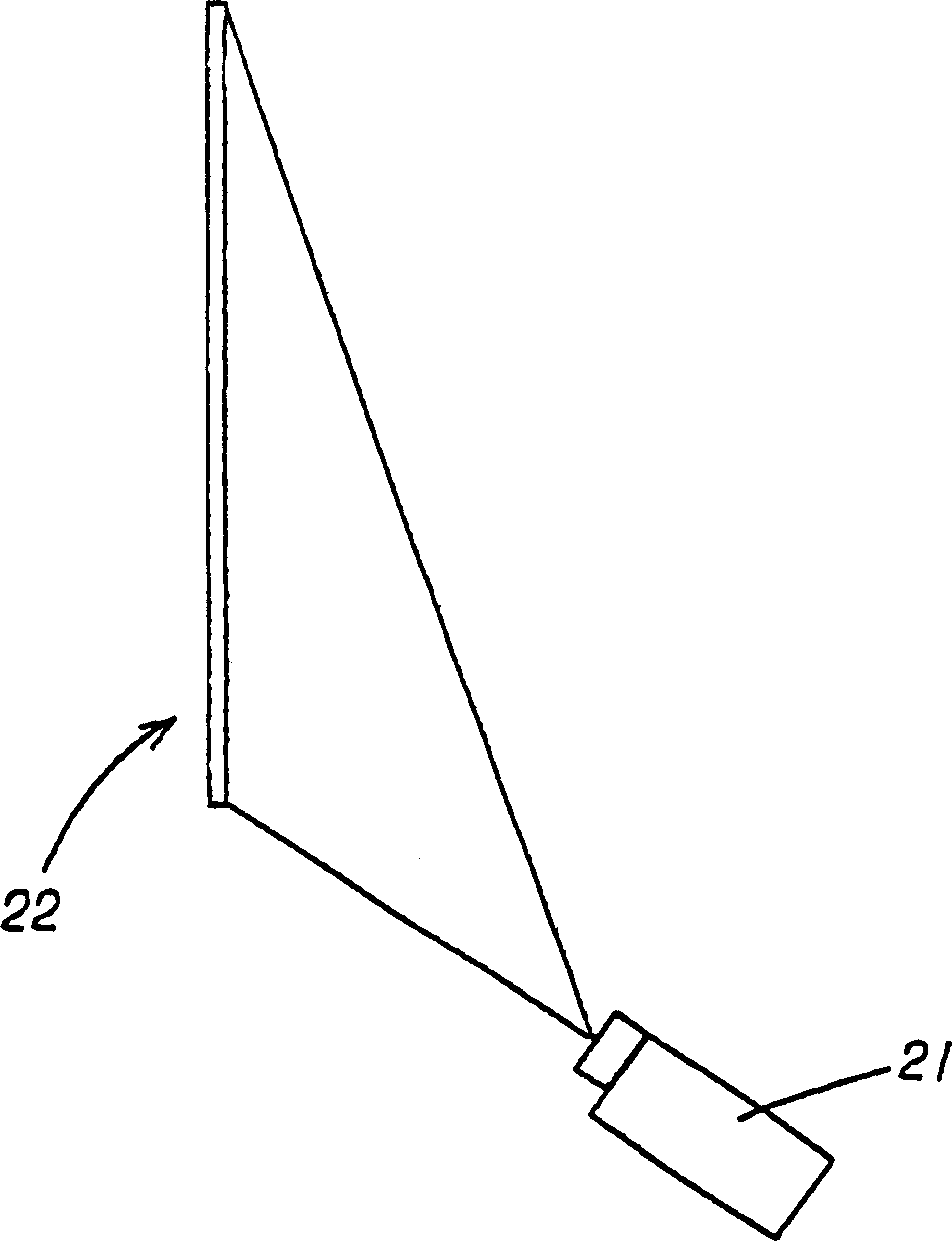

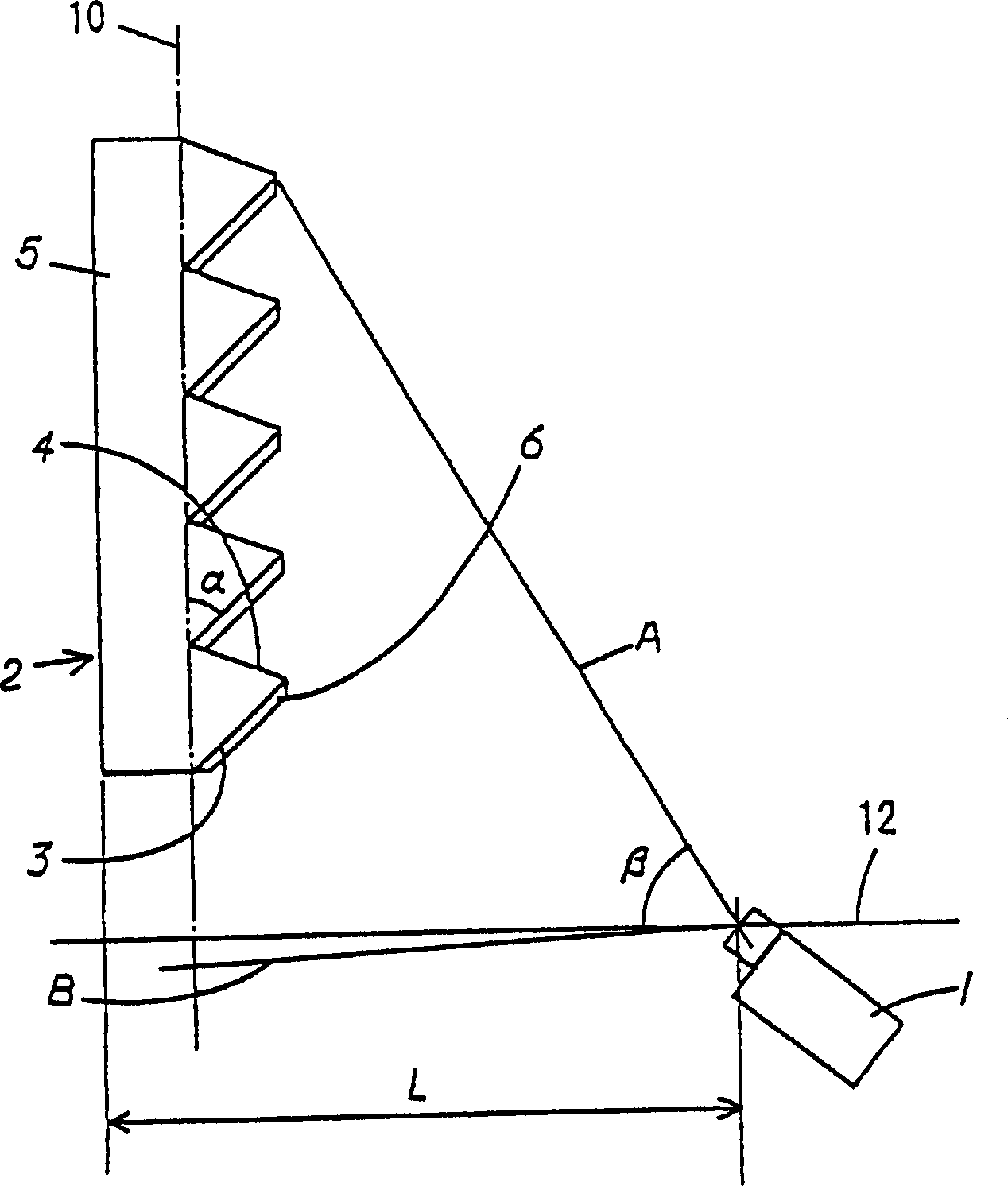

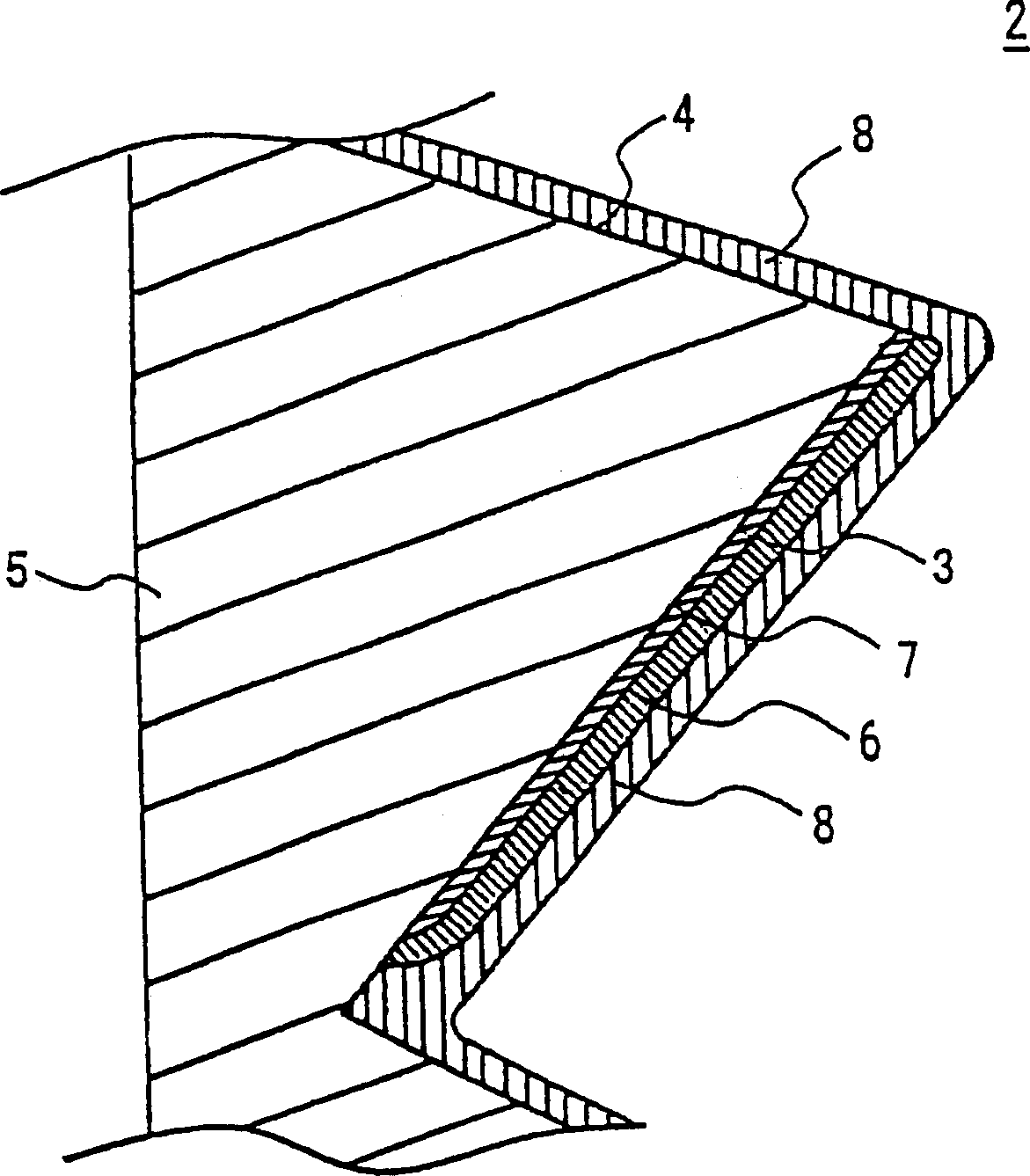

[0028] figure 2 is a view showing the basic structure of the reflective screen 2 according to the embodiment of the present invention. The reflective screen 2 includes a base material 5 having a projector-side slope 3 and a non-projector-side slope 4 , and a white resin layer 6 . The base material 5 is made of a light-absorbing material. Set the projector side slope 3 at an angle so that light from projector 1 enters the projector side slope 3, and set the non-projector side slope 4 at an angle so that light from projector 1 does not enter the non-projector side slope 4, and the projector-side slop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com