Highly efficient thermoelectric material

A thermoelectric material, high-efficiency technology, applied in the direction of thermoelectric device junction lead-out material, thermoelectric device, circuit, etc., can solve the problem of hot end solder temperature limitation, thermal expansion difference between cold and hot solder ends, and inability to increase the temperature difference range, etc. Solving the limitation of temperature, the effect of high thermoelectric figure of merit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

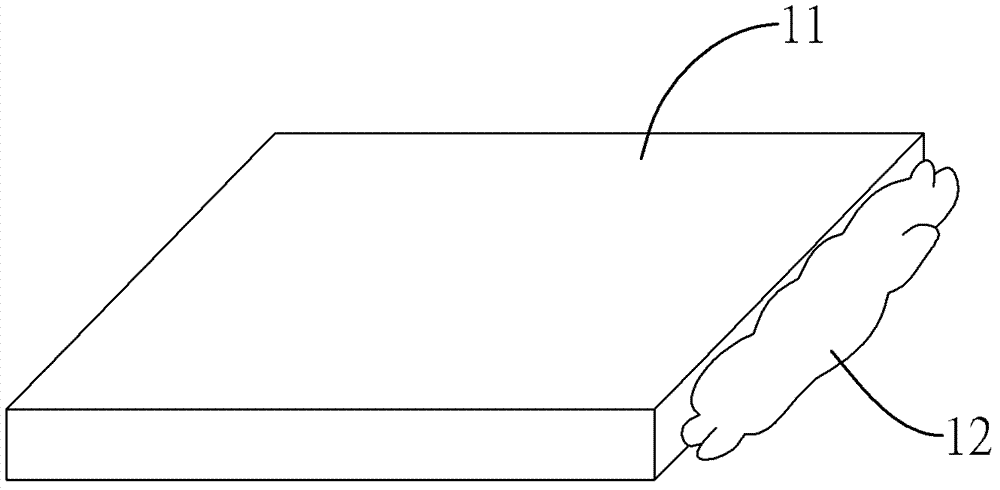

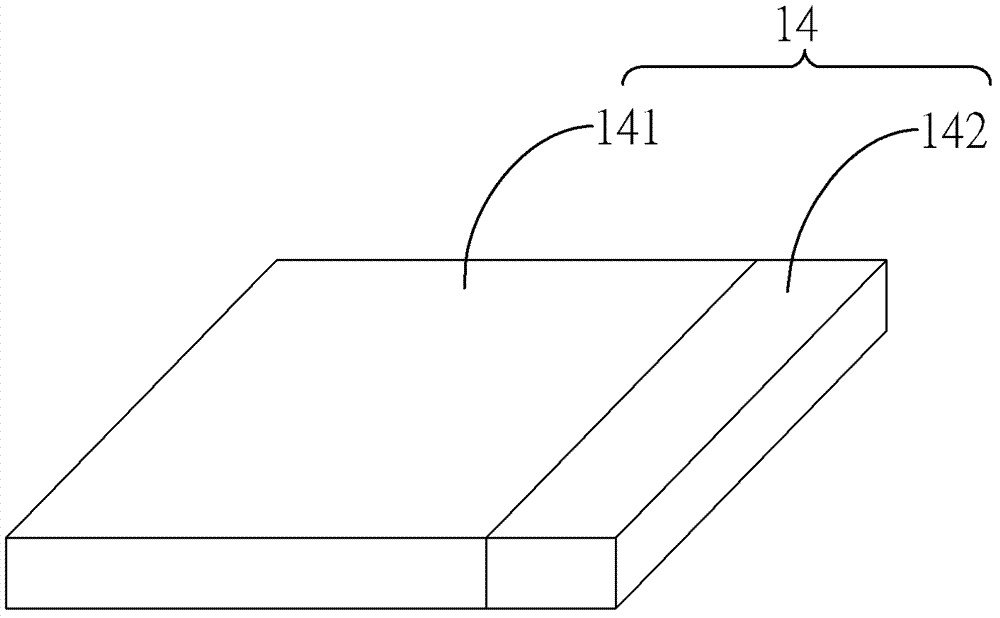

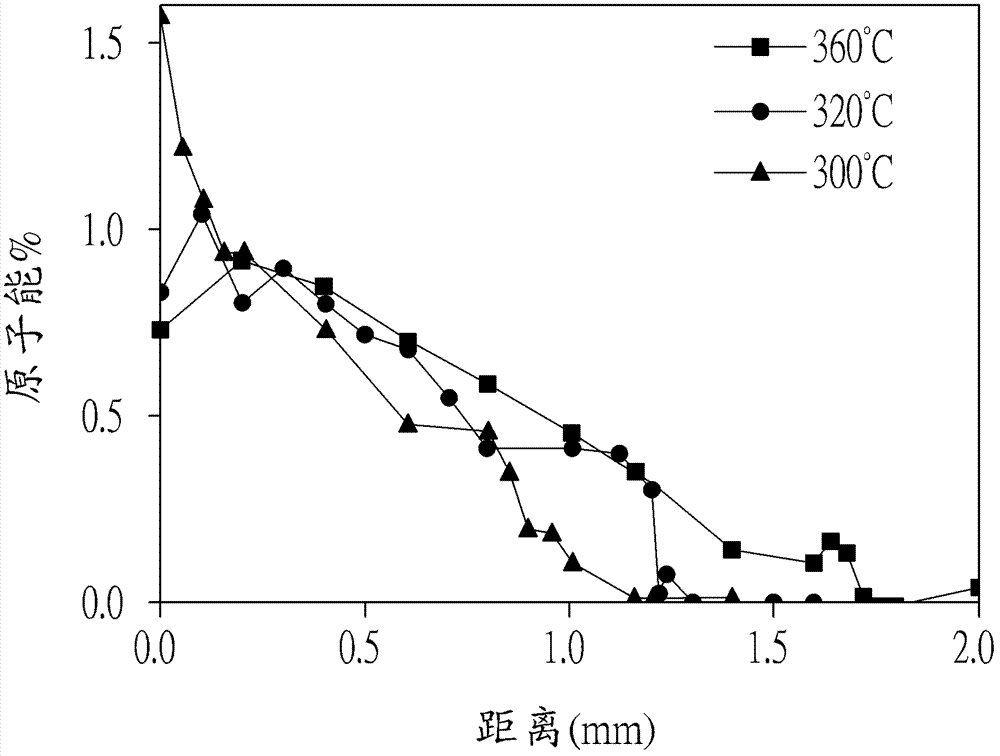

[0024] Please also see Figure 1a to Figure 1b As shown, the high-efficiency thermoelectric material provided by the present invention is firstly selected from a thermoelectric substrate 11 (such as Figure 1a shown), which includes a high carrier concentration region and a low carrier concentration region (not shown in the figure), and then the silver element is made into a silver glue 12, and then the silver glue 12 is coated on the thermoelectric substrate 11, and use a high-temperature furnace (not shown in the figure) to carry out a heating and diffusion program on the thermoelectric substrate 11 coated with the silver glue 12, and the heating and diffusion program is applied at a temperature of 250° C. to 350° C. The thermoelectric substrate 11 of the silver paste 12 is continuously heated for two hours, so that the silver paste 12 can be doped into one end of the thermoelectric substrate 11 to make a heterogeneous thermoelectric substrate 14, and the anisotropic thermoel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com