Thermoelectric material and manufacturing method thereof

A technology of thermoelectric materials and raw materials, applied in the field of materials engineering, can solve the problems of few types of thermoelectric materials and limited thermoelectric materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

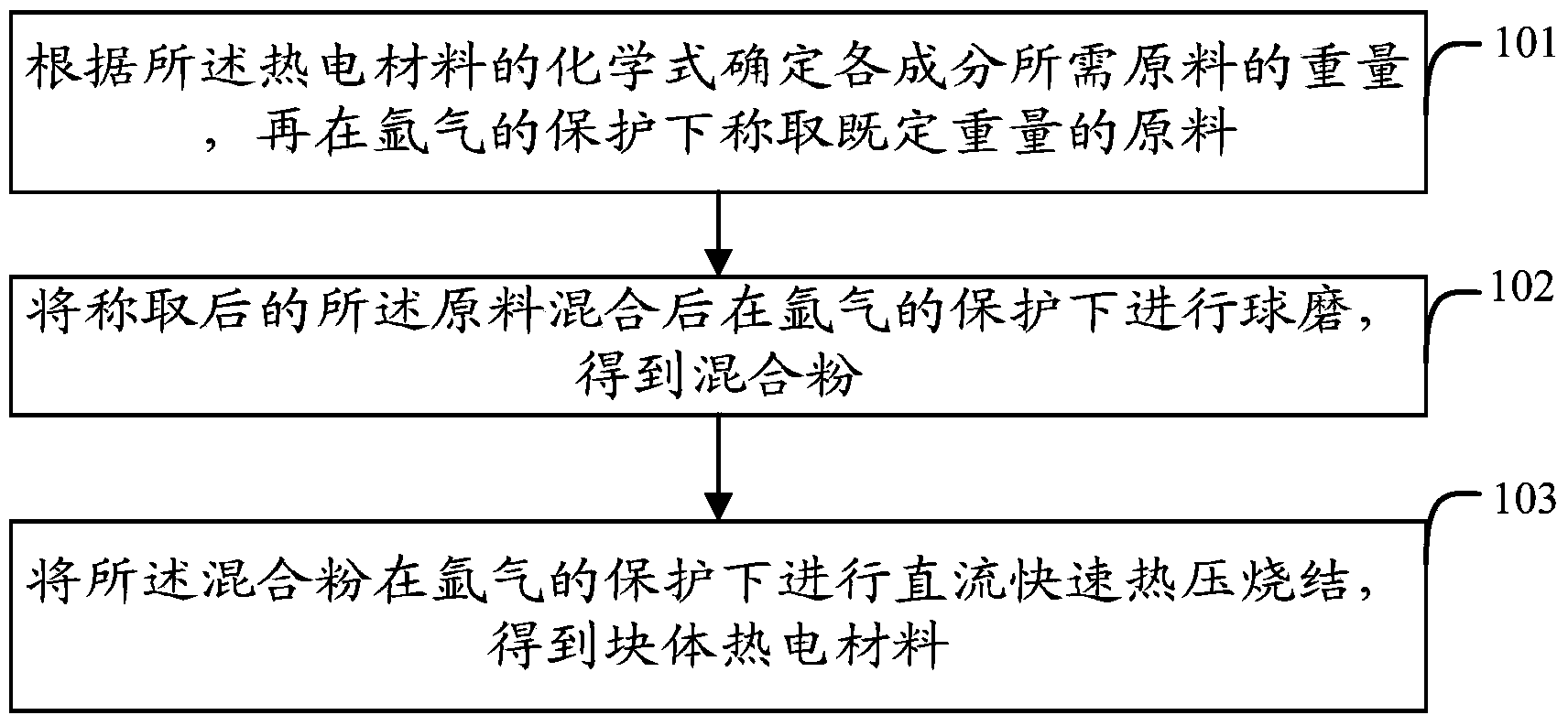

[0038] In addition, in the present invention, the preparation method of the thermoelectric material includes the following steps:

[0039] Step 101: Determine the weight of raw materials required for each component according to the chemical formula of the thermoelectric material, and then weigh the raw materials with a predetermined weight under the protection of argon;

[0040] More specifically, in this step, the raw material is a simple substance or an intermediate alloy composed of two or more corresponding elements, and the process of weighing the raw material can be carried out in a glove box, and the water content in the glove box is <0.1ppm. Oxygen content <0.1ppm.

[0041] Under the protection of argon, various raw materials can be prevented from being oxidized, thereby making the performance of each raw material stable, and avoiding the decline of thermoelectric performance parameters after being oxidized.

[0042] Step 102: mixing the weighed raw materials and ball...

Embodiment 1

[0050] A kind of thermoelectric material is provided in the embodiment of the present invention, and its chemical formula is: Ge 0.94 Pb 0.01 Bi 0.05 Te.

[0051] Its preparation method is: using Ge, Te, Pb and Bi simple substances as raw materials, according to the chemical molecular formula Ge 0.94 Pb 0.01 Bi 0.05 Te was weighed and proportioned in the glove box. Among them, the water content of the glove box is less than 0.1ppm, and the oxygen content is less than 0.1ppm; put the weighed raw materials together with the balls into the ball mill tank, and use a 3-dimensional high-performance ball mill to prepare fine mixed powder under the protection of Ar. The ratio is 2:1, the speed of the ball mill is 1500 rpm, and the ball milling time is 8-10 hours; the powder obtained by the ball mill is subjected to direct current rapid hot-pressing sintering in a vacuum environment, and the vacuum degree is 1×10 -2 Pa, pressure 30-60MPa, sintering temperature 500°C, holding time...

Embodiment 2

[0054] A kind of thermoelectric material is provided in the embodiment of the present invention, and its chemical formula is: Ge 0.92 Pb 0.03 Bi 0.05 Te.

[0055] Its preparation method includes: using Ge, Te, Pb and Bi simple substances as raw materials, according to the chemical molecular formula Ge 0.92 Pb 0.03 Bi 0.05 Te is weighed and proportioned in the glove box, wherein the water content of the glove box is -2 Pa, pressure 30-60MPa, sintering temperature 500°C, holding time 2 minutes, GeTe-based thermoelectric material Ge 0.92 Pb 0.03 Bi 0.05 Te.

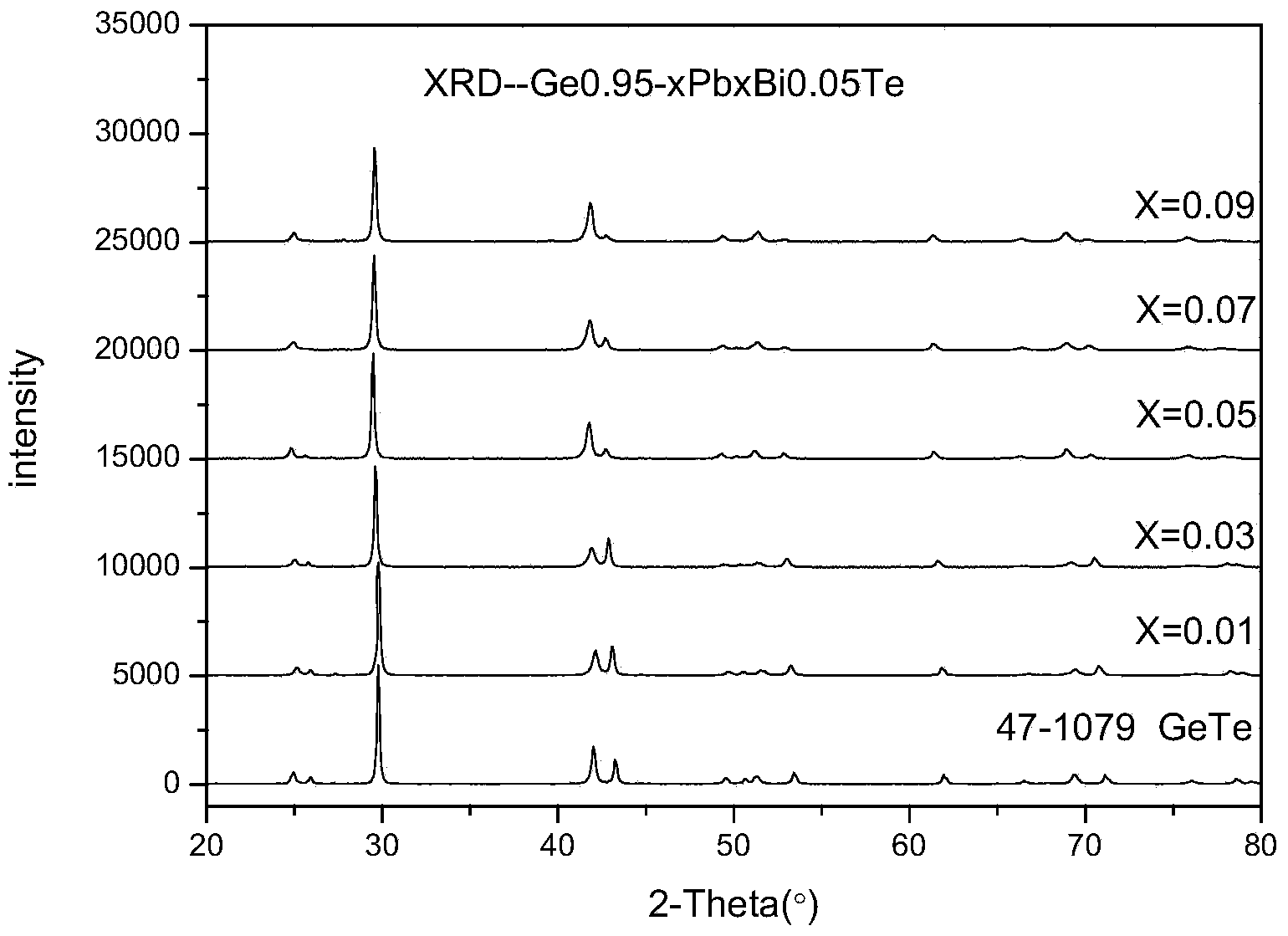

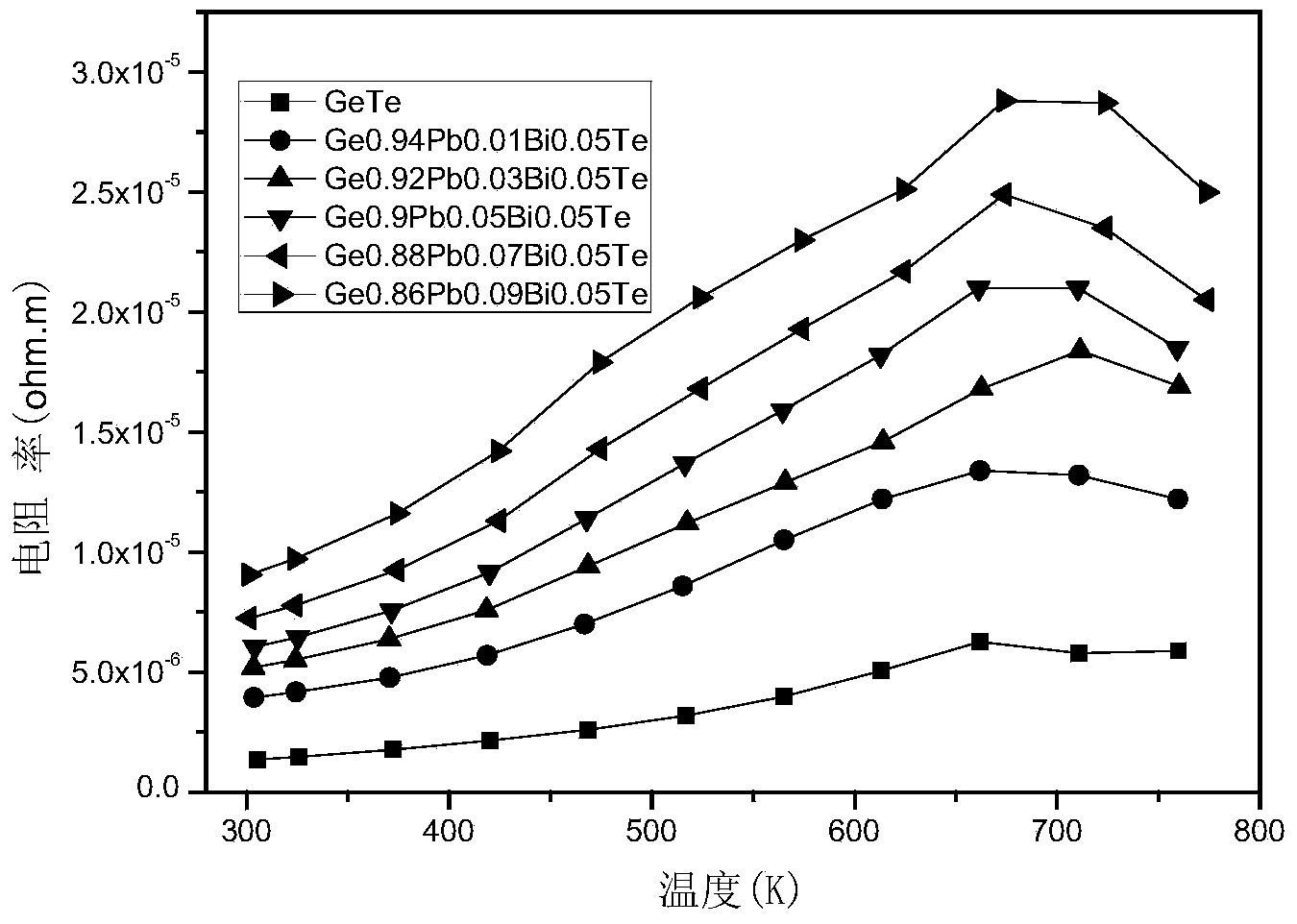

[0056] The thermoelectric material Ge that present embodiment makes 0.92 Pb 0.03 Bi 0.05 The phase and thermoelectric properties of Te are as follows: Figure 2-6 As shown, its thermal conductivity is 1.282W / m.K at 673K, which is 47% of 2.741W / m.K at the same temperature of pure GeTe; and its maximum figure of merit (ZT) is 1.78, which is 73% higher than 1.03 of pure GeTe .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com