Hot extrusion forming method of bismuth telluride thermoelectric material

A technology of thermoelectric materials and molding methods, which is applied in the direction of thermoelectric device node lead-out materials, thermoelectric device manufacturing/processing, etc., can solve the problems of weak mechanical properties and poor processability, and achieve high thermoelectric value, high strength, Solve the effect of low reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] S1. Raw material crushing: Take out the raw materials tellurium ingot, bismuth ingot and selenium ingot from the vacuum cabinet respectively, put them into the powder tank and smash the materials into small pieces. Open the lid of the powder tank, and use tweezers to pick up small pieces with a diameter of no more than 30mm and place them on clean filter paper. Crushing the raw material into small pieces can make the raw material smelt better in step S2.

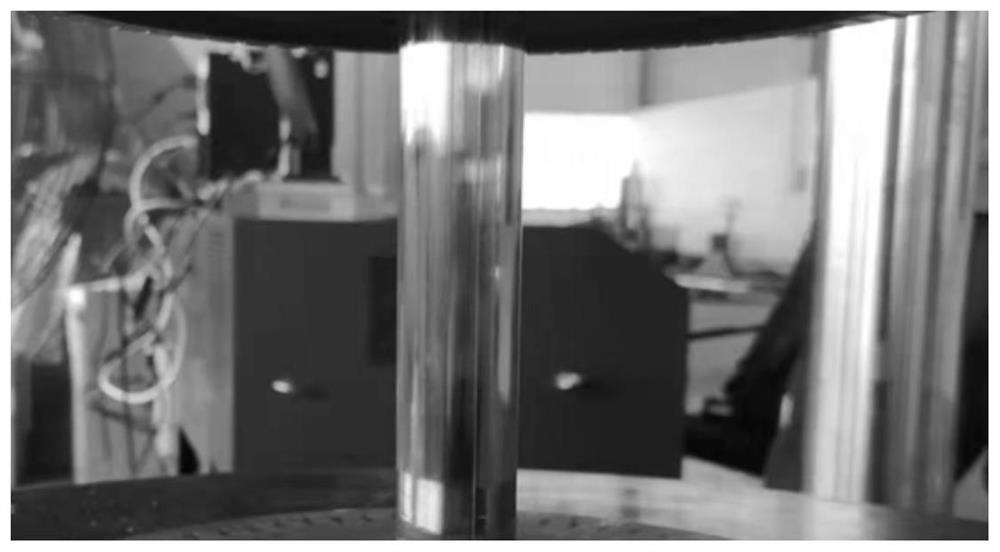

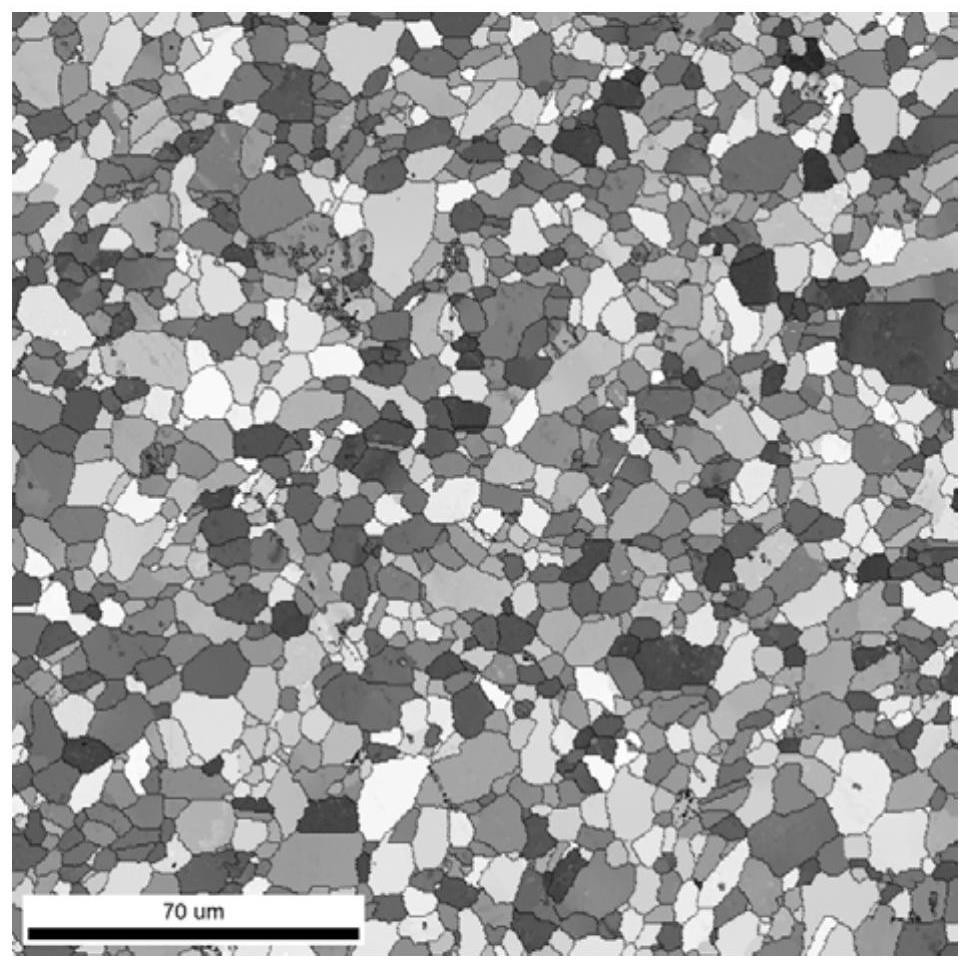

[0049] S2. High-frequency melting: Weigh the raw materials obtained in step S1 according to the stoichiometric ratio of Bi2Te2.8Se0.2, mix the raw materials and put them into a graphite crucible for melting in a vacuum high-frequency induction melting furnace with a heating rate of 20oC / min. The melting temperature is 800oC, and the melting time is 4h. Using high-frequency melting can overcome the defects of segregation or free of material components to the greatest extent, and prepare materials with uniform componen...

Embodiment 2

[0054] S1. Raw material crushing: Take out the raw materials tellurium ingot, bismuth ingot and antimony ingot from the vacuum cabinet respectively, put them into the powder tank and smash the materials into small pieces. Open the lid of the powder tank, and use tweezers to pick up small pieces with a diameter of no more than 30mm and place them on clean filter paper. Crushing the raw material into small pieces can make the raw material smelt better in step S2.

[0055] S2. High-frequency melting: Weigh the raw materials obtained in step S1 according to the stoichiometric ratio of Bi0.4Sb1.6Te3, mix the raw materials and put them into a graphite crucible for melting in a vacuum high-frequency induction melting furnace with a heating rate of 25oC / min. The melting temperature is 850oC, and the melting time is 3h. Using high-frequency melting can overcome the defects of segregation or free of material components to the greatest extent, and prepare materials with uniform componen...

Embodiment 3

[0060] S1. Raw material crushing: Take out the raw materials tellurium ingot, bismuth ingot and selenium ingot from the vacuum cabinet respectively, put them into the powder tank and smash the materials into small pieces. Open the lid of the powder tank, and use tweezers to pick up small pieces with a diameter of no more than 30mm and place them on clean filter paper. Crushing the raw material into small pieces can make the raw material smelt better in step S2.

[0061] S2. High-frequency melting: Weigh the raw materials obtained in step S1 according to the stoichiometric ratio of Bi2Te2.7Se0.3, mix the raw materials and put them into a graphite crucible for melting in a vacuum high-frequency induction melting furnace with a heating rate of 20oC / min. The melting temperature is 800oC, and the melting time is 4h. Using high-frequency melting can overcome the defects of segregation or free of material components to the greatest extent, and prepare materials with uniform componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com