High-temperature quantum well super-lattice thick film thermoelectric material and production method thereof

A high-temperature quantum well, thermoelectric material technology, applied in thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, nanotechnology for materials and surface science, etc., can solve the problem that nanowires do not have quantum wells or atoms Layer interface structure, high material cost, unsatisfactory quality and other problems, to achieve the effect of self-powered use, high thermoelectric figure of merit, and abundant reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The production method of the high-temperature quantum well superlattice thick-film thermoelectric material comprises the following steps:

[0055] (1) Pulse Si gas phase precursor:

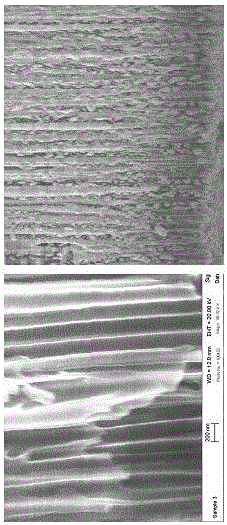

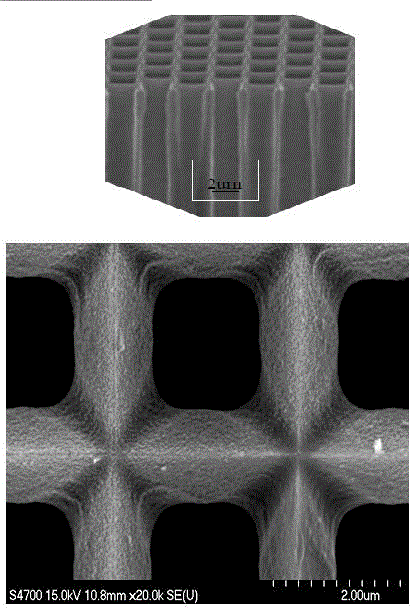

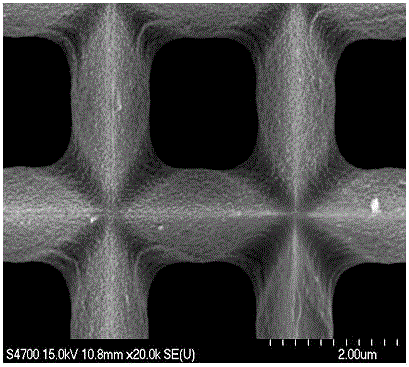

[0056] Into the reaction chamber, the Si gas phase precursor is continuously introduced, and the Si gas phase precursor is three (dimethylamino) silicon, Tris (dimethylamino) silicon, 3DMAS, 99.9999%; the substrate substrate temperature in the reaction chamber is 200 o C-400 o C; The substrate is an alumina nanoporous substrate;

[0057] (2) Clean Si gas phase precursor:

[0058] When the surface of the alumina nanoporous substrate reaches the saturation state of chemical adsorption, stop introducing the Si gas phase precursor; introduce an inert gas simultaneously to clean up the remaining Si gas phase precursor in the reaction chamber;

[0059] (3) Pulse Ge gas phase precursor:

[0060] Into the reaction chamber, the Ge gas phase precursor is continuously introduced; the Ge gas phase...

Embodiment 2

[0092] The difference between this embodiment 2 and embodiment 1 is that the substrate is a doped porous silicon template; the substrate substrate temperature in the reaction chamber is 350 o C; heating temperature of the reaction chamber: 350° C.; the same parts will not be described in detail.

Embodiment 3

[0094] The difference between this embodiment and Embodiment 2 is that the substrate is a doped silicon substrate; the temperature of the substrate in the reaction chamber is 350 o C; heating temperature of the reaction chamber: 350° C.; the same parts will not be described in detail.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com