Composite strontium titanate thermoelectric material and preparation method thereof

A technology of thermoelectric materials and composite titanium, which is applied in the field of composite strontium titanate thermoelectric materials and its preparation, can solve the problems of disparity and unfavorable large-scale application of thermoelectric materials, and achieve the effect of reducing thermal conductivity and improving thermoelectric merit value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment discloses a method for preparing a composite strontium titanate thermoelectric material, including a mixing step, a pressing step and a sintering step. The above steps will be specifically described below.

[0025] (1) Mixing step

[0026] Firstly, the components needed for composite thermoelectric materials are synthesized: potassium titanate nanowires and niobium-doped strontium titanate powder.

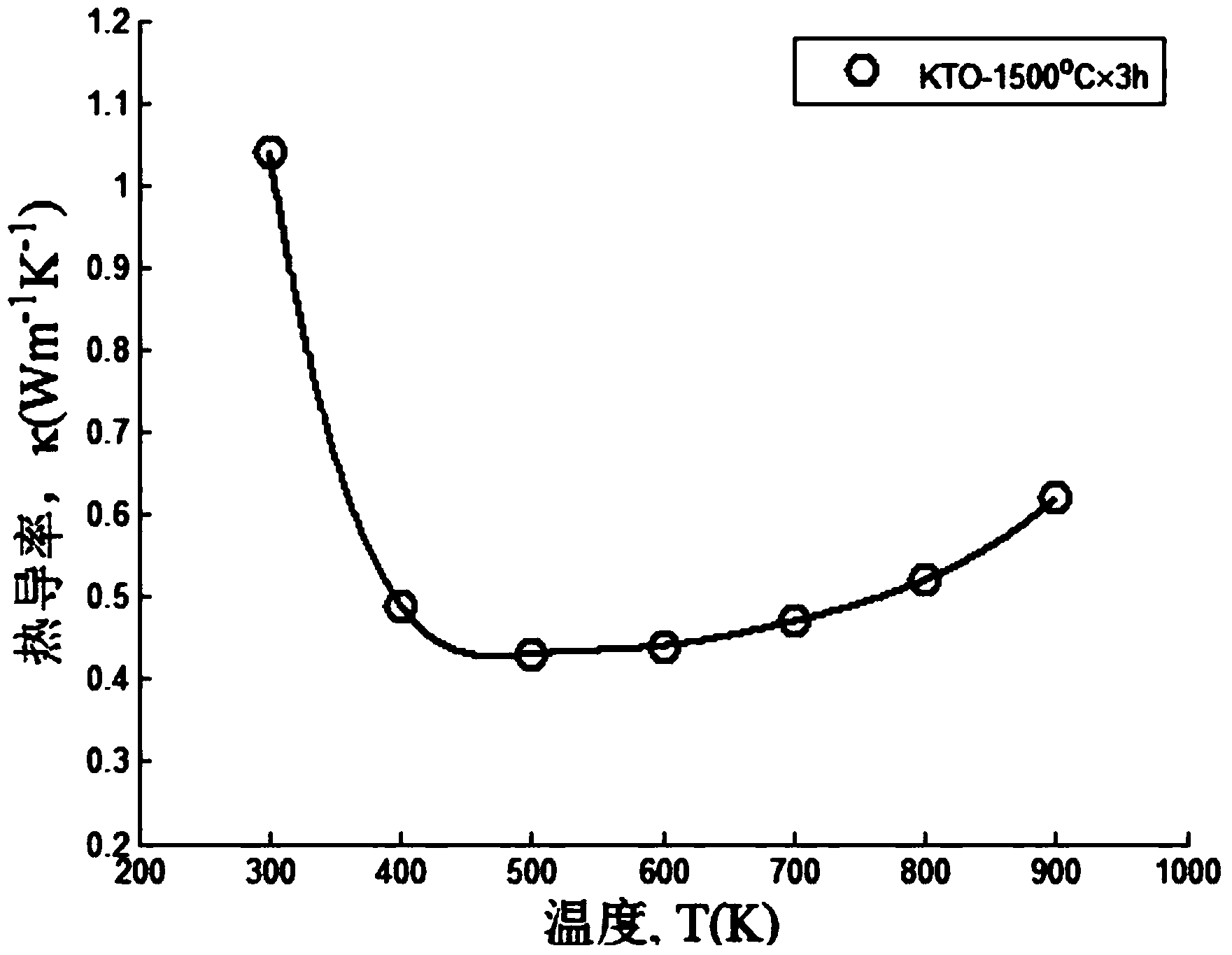

[0027] Potassium titanate nanowires can be synthesized by known methods in the prior art. In the present invention, KOH and TiO 2 Potassium titanate nanowires were prepared by hydrothermal synthesis. The preparation process refers to "Meng X, Wang D, Liu B, Fu Z. Effect of titania different phases on the microstructure and properties of K 2 Ti 6 o 13 nanowires[J], 137:146-149", specifically: combining KOH and TiO 2 Place it in a reaction kettle and react for 40-60h at a reaction temperature of 160-180°C. Among them, the concentration of KOH is 15-30mo...

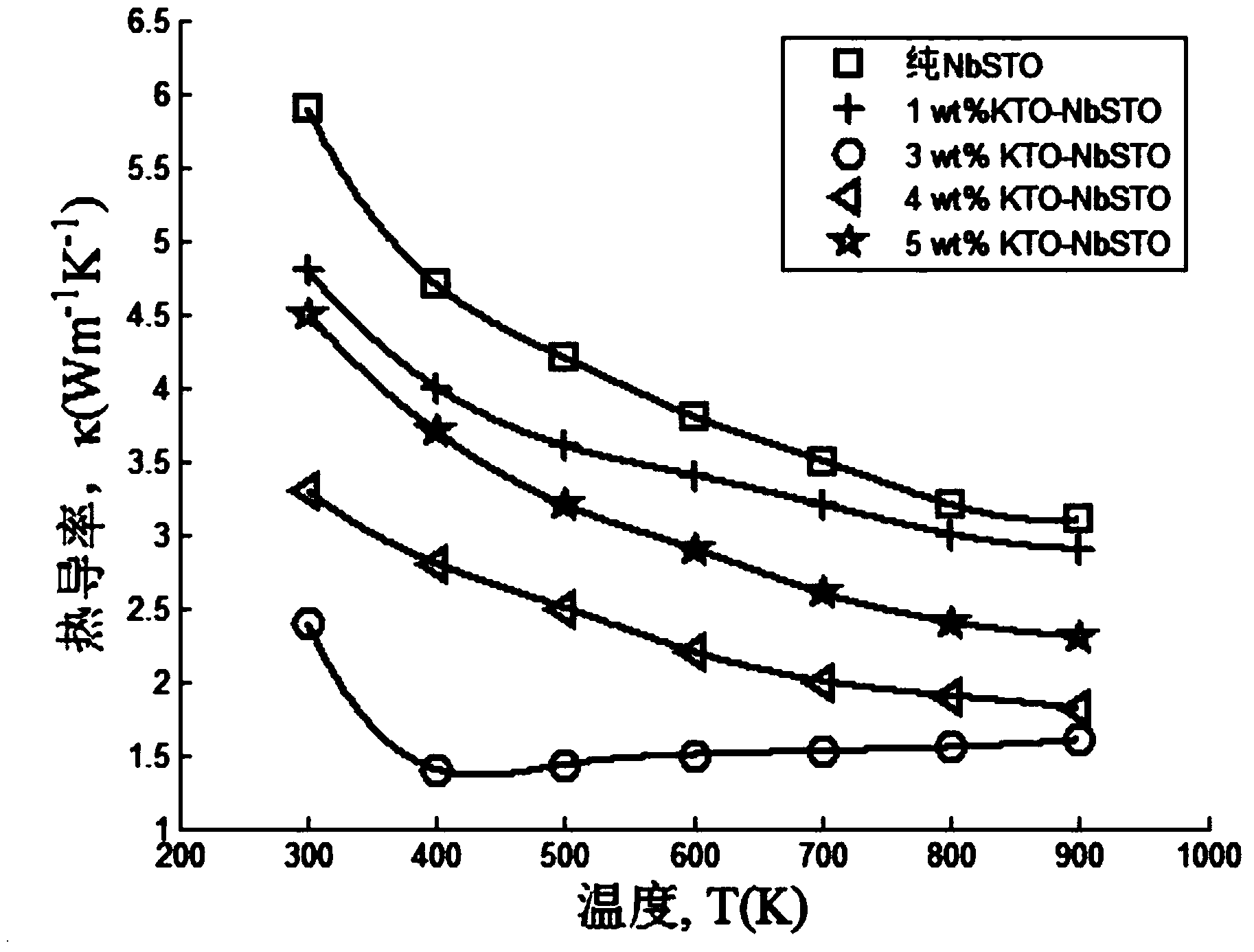

Embodiment 2

[0035] This example discloses a method for preparing a composite strontium titanate thermoelectric material, the preparation process of which is the same as that of Example 1, the only difference being that in the mixing step, the weight of the niobium-doped strontium titanate powder is used as the benchmark , uniformly mixing 3% potassium titanate nanowire powder into the niobium-doped strontium titanate powder to obtain a mixture.

Embodiment 3

[0037] This example discloses a method for preparing a composite strontium titanate thermoelectric material, the preparation process of which is the same as that of Example 1, the only difference being that in the mixing step, the weight of the niobium-doped strontium titanate powder is used as the benchmark , uniformly mixing 5% potassium titanate nanowire powder into the niobium-doped strontium titanate powder to obtain a mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com