Low-cost environment-friendly SnS-based thermoelectric material and preparation method thereof

An environment-friendly, thermoelectric material technology, which is applied in the direction of thermoelectric device node lead-out materials, thermoelectric device manufacturing/processing, etc., can solve the problems of poor thermoelectric performance and achieve high thermoelectric value of merit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

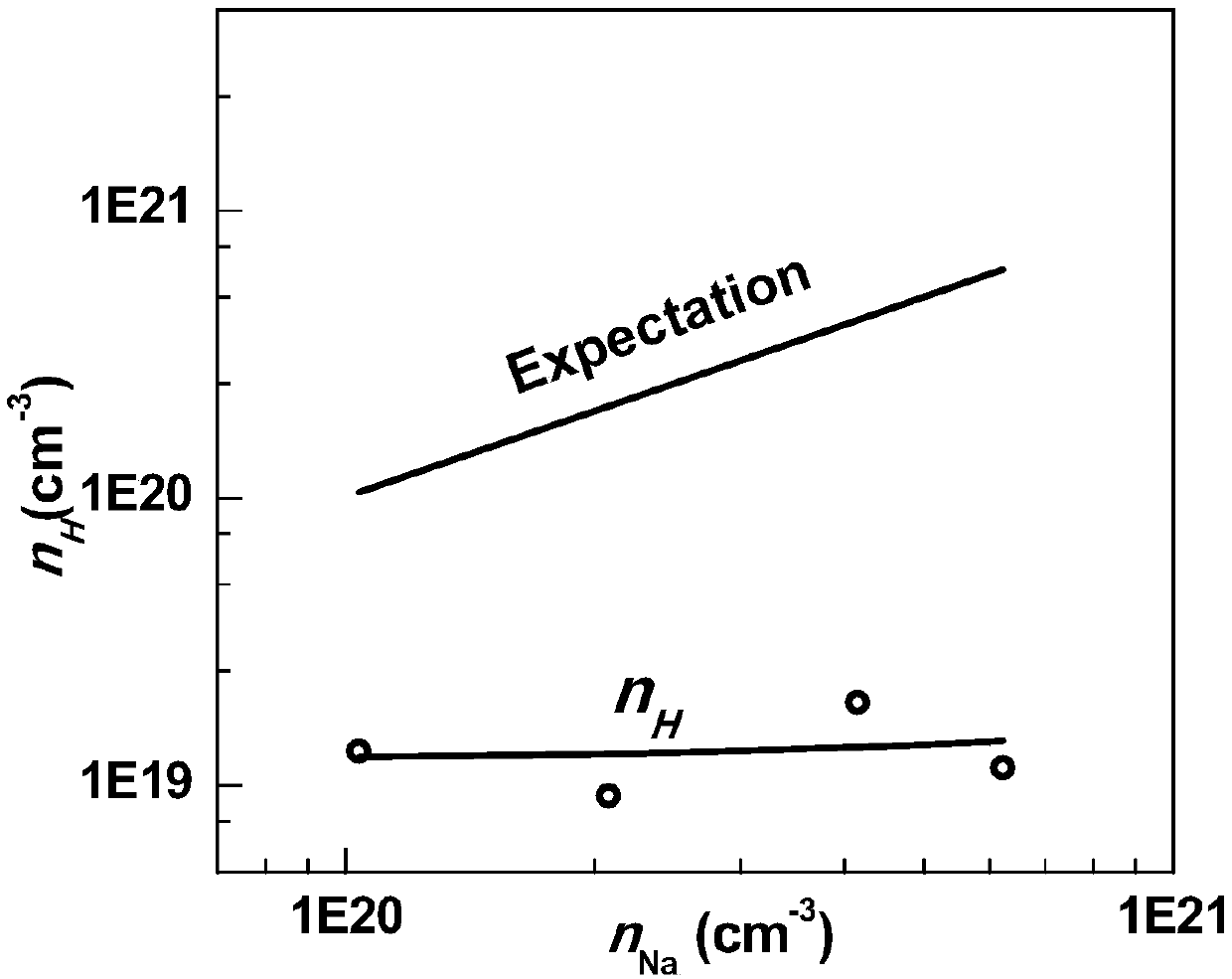

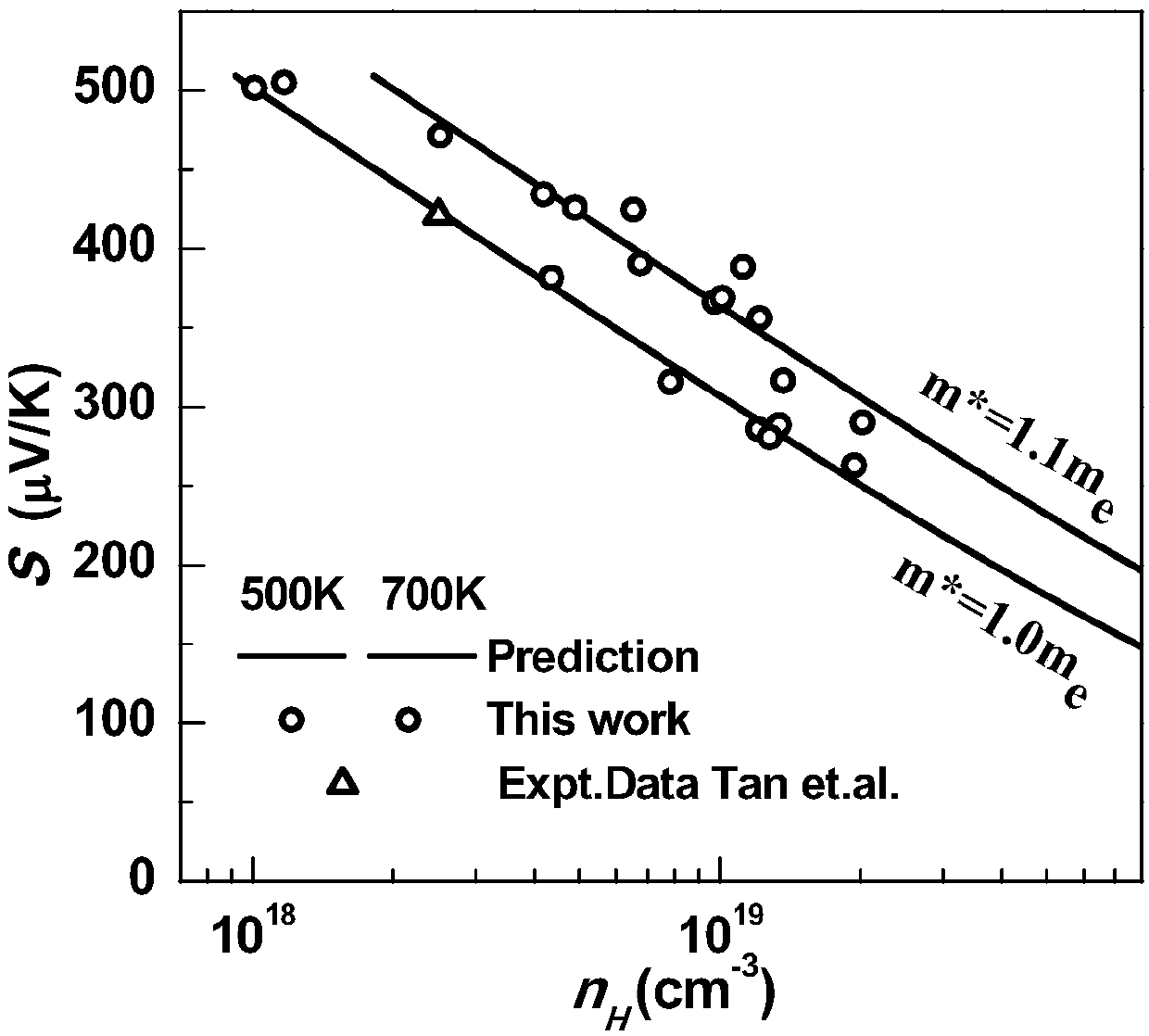

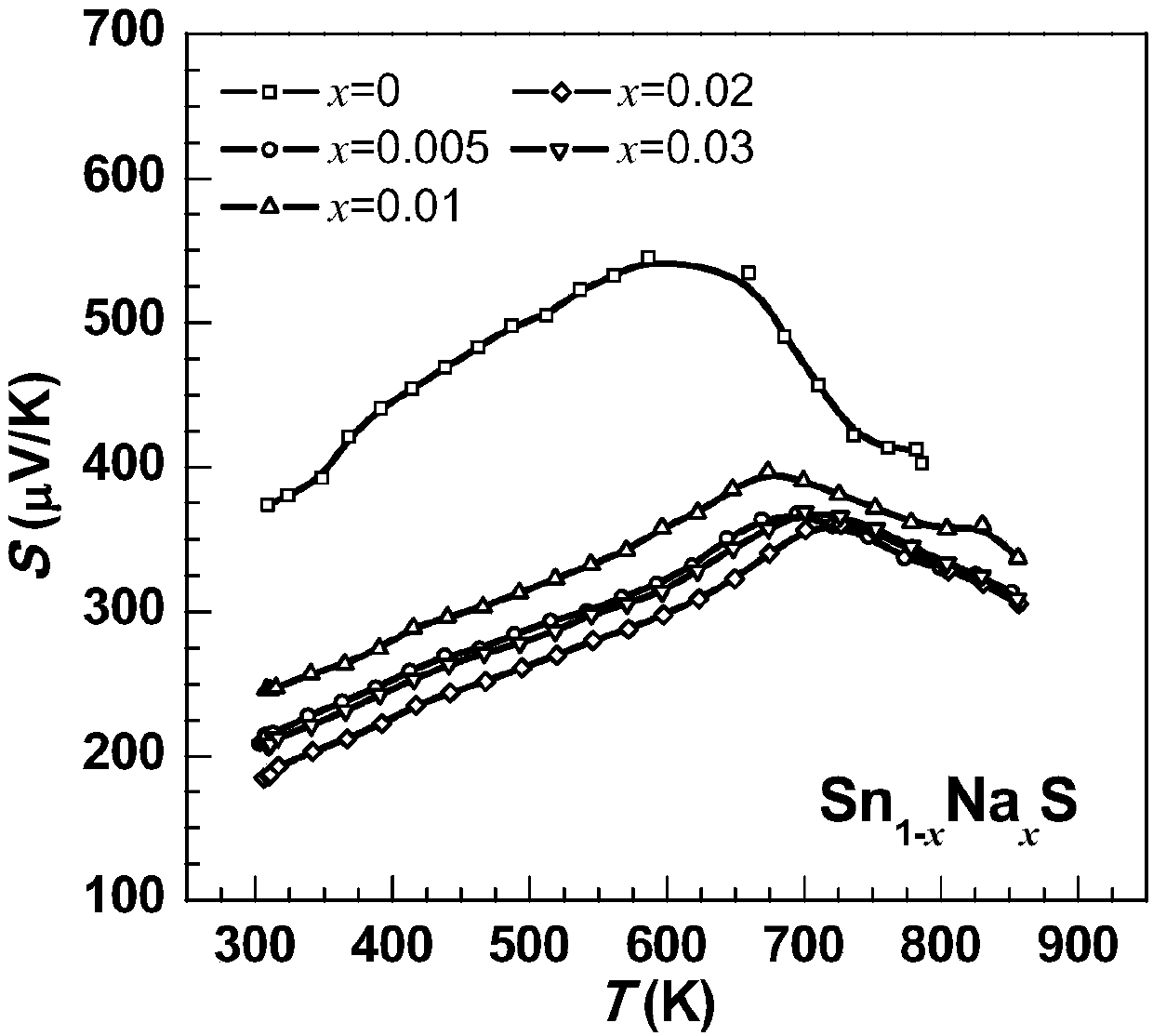

[0041] A kind of SnS based thermoelectric material, the chemical formula is Sn 1-x Na x S(x≤0.03), take x=0, 0.005, 0.01, 0.02, 0.03 to prepare SnS-based bulk materials with different carrier concentrations:

[0042] (1) According to different x values, press Sn 1-x Na x The stoichiometric ratio of S (x≤0.03) Weigh elemental raw materials tin Sn, sodium Na, and sulfur S with a purity greater than 99.99%, put them into a quartz tube, and pack after vacuumizing;

[0043] (2) Place the vacuum-encapsulated quartz tube in a high-temperature well-type furnace, raise the temperature from room temperature to 920° C. at a rate of 100° C. / h, keep it for 4 hours, and then quench it to obtain the first ingot.

[0044] (3) Perform high-temperature annealing heat treatment on the first ingot obtained in step (2), place the quartz tube with the first ingot in the pit furnace again, and raise the temperature from room temperature to 650°C at a rate of 150°C / h , quenching and cooling after...

Embodiment 2

[0051] Compared with Example 1, most of them are the same, except that the preparation method in this example is:

[0052] (1) Press Sn 1-x Na x The stoichiometric ratio of S (x≤0.03) Weigh elemental raw materials tin Sn, sodium Na, and sulfur S with a purity greater than 99.99%, put them into a quartz tube, and pack after vacuumizing;

[0053] (2) Place the vacuum-encapsulated quartz tube in a high-temperature well-type furnace, raise the temperature from room temperature to 950° C. at a rate of 120° C. / h, keep it for 3 hours, and then quench it to obtain the first ingot.

[0054] (3) Perform high-temperature annealing heat treatment on the first ingot obtained in step (2), place the quartz tube with the first ingot in the pit furnace again, and raise the temperature from room temperature to 700°C at a rate of 200°C / h , quenching and cooling after heat preservation for 2 days to obtain the second ingot.

[0055] (4) Grind the second ingot obtained in step (3) into powder, ...

Embodiment 3

[0057] Compared with Example 1, most of them are the same, except that the preparation method in this example is:

[0058] (1) Press Sn 1-x Na x The stoichiometric ratio of S (x≤0.03) Weigh elemental raw materials tin Sn, sodium Na, and sulfur S with a purity greater than 99.99%, put them into a quartz tube, and pack after vacuumizing;

[0059] (2) Place the vacuum-encapsulated quartz tube in a high-temperature well-type furnace, raise the temperature from room temperature to 930° C. at a rate of 110° C. / h, keep it for 5 hours, and then quench it to obtain the first ingot.

[0060] (3) Perform high-temperature annealing heat treatment on the first ingot obtained in step (2), place the quartz tube with the first ingot in the pit furnace again, and raise the temperature from room temperature to 660°C at a rate of 180°C / h , quenching and cooling after 4 days of heat preservation to obtain the second ingot.

[0061] (4) Grind the second ingot obtained in step (3) into powder, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com