P-type skutterudite material and preparation method thereof

A skutterudite and p-type technology, which is applied in the direction of thermoelectric device node lead-out materials, thermoelectric device manufacturing/processing, etc., can solve the problems of material electrical transmission performance deterioration, uniform dispersion of nanoparticles, lack of multi-filling materials, etc. Achieve the effects of theoretical thermoelectric conversion efficiency improvement, power factor improvement, and industrialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

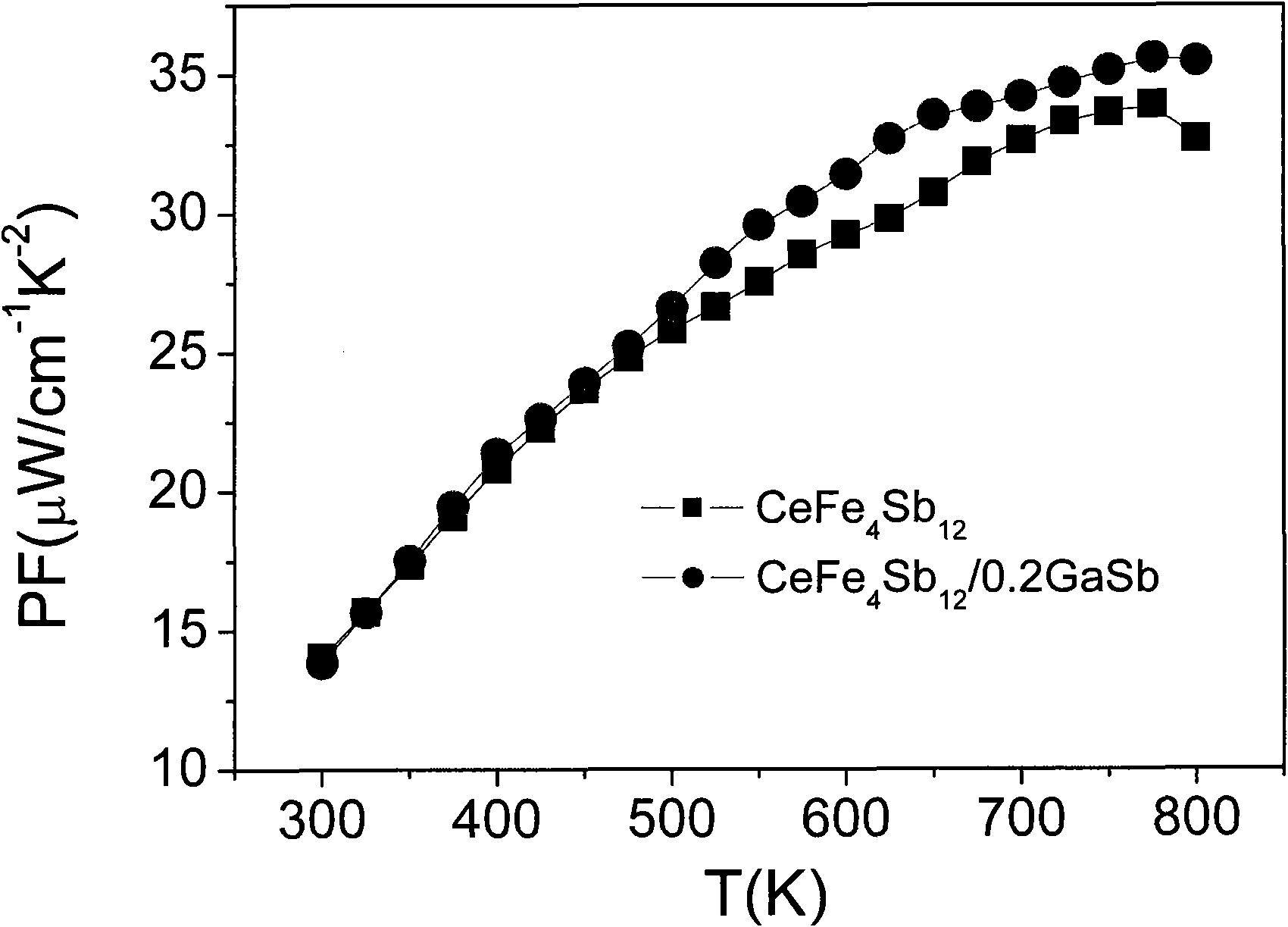

[0102] Example 1: CeFe 4 Sb 12 / 0.2GaSb composite material

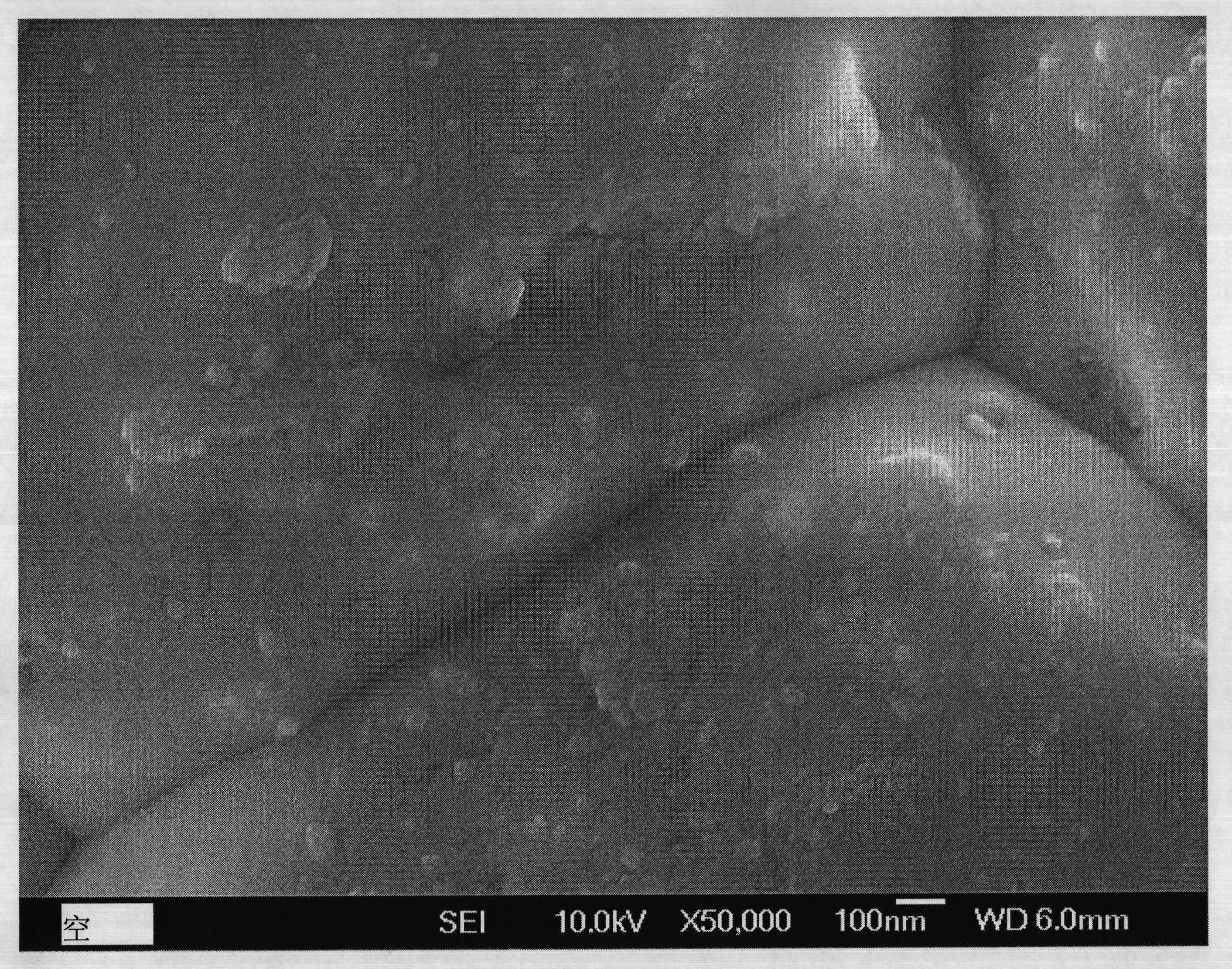

[0103] The metal raw materials Ce, Fe, Sb, and Ga are mixed in the glove box according to the molar ratio of 1:4:12.2:0.2, and the raw materials are sealed in a quartz tube with a carbon film on the inner wall, and the vacuum is drawn while using argon plasma The flame is used for packaging, and the quartz tube is filled with a small amount of Ar gas for protection. The mixed raw materials were melted at 1000° C. for 12 hours. Quenching is carried out after melting, the quenching medium is brine, and the quenching speed is about 300°C / s. After quenching, the quartz tube was annealed at 700°C for 120 hours, and the obtained block was ground into fine powder and then subjected to spark plasma sintering. The sintering temperature was 600°C, the holding time was 5 minutes, and the pressure was 50MPa. The field emission SEM pictures show that the second phase (GaSb phase) is well distributed on or within the...

Embodiment 2

[0104] Example 2: Ce 0.45 Nd 0.45 Fe 3 CoSb 12 Material

[0105] The metal raw materials Ce, Nd, Fe, Co, Sb are mixed in the glove box according to the molar ratio of 0.45:0.45:3:1:12, and the raw materials are sealed into the quartz tube with the carbon film evaporated on the inner wall, and the vacuum is drawn It is packaged with an argon plasma flame, and a small amount of Ar gas is filled in the quartz tube for protection. The mixed raw materials were heated to 1100°C at a rate of 3°C per minute and melted for 12 hours. Quenching is carried out after melting, the quenching medium is brine, and the quenching speed is about 300°C / s. The quenched ingot and the quartz tube were annealed at 600°C for 200 hours. The block was ground into fine powder and then spark plasma sintered. The sintering temperature was 600°C, the holding time was 10 minutes, and the pressure was 60MPa. Tests showed that Ce 0.45 Nd 0.45 Fe 3 CoSb 12 Has a ratio of (single) fill...

Embodiment 3

[0106] Example 3: Ce y Fe x co 4-x Sb 12 / 0.1GaSb material

[0107] The metal raw materials Ce, Fe, Co, Sb, and Ga are mixed in the glove box according to the molar ratio of 0.6:0.4:3:1:12.1:0.1, and the raw materials are sealed in a quartz tube with a carbon film evaporated on the inner wall. The vacuum side is sealed with an argon plasma flame, and a small amount of Ar gas is filled in the quartz tube for protection. The mixed raw materials were heated to 1050°C at a rate of 1°C per minute and melted for 10 hours. Quenching is carried out after melting, and the quenching medium is brine. The ingot obtained by quenching was annealed at 650°C for 96 hours together with the quartz tube. The block was ground into fine powder and then spark plasma sintered. The sintering temperature was 550°C, the holding time was 20 minutes, and the pressure was 50MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com