P-type skutterudite material and preparation method thereof

一种方钴矿、p型的技术,应用在热电器件结点引出线材料、热电器件的制造/处理等方向,能够解决材料电传输性能恶化、纳米颗粒均匀分散、缺乏多填充材料等问题,达到理论热电转换效率提高、功率因子提升、产业化前景好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

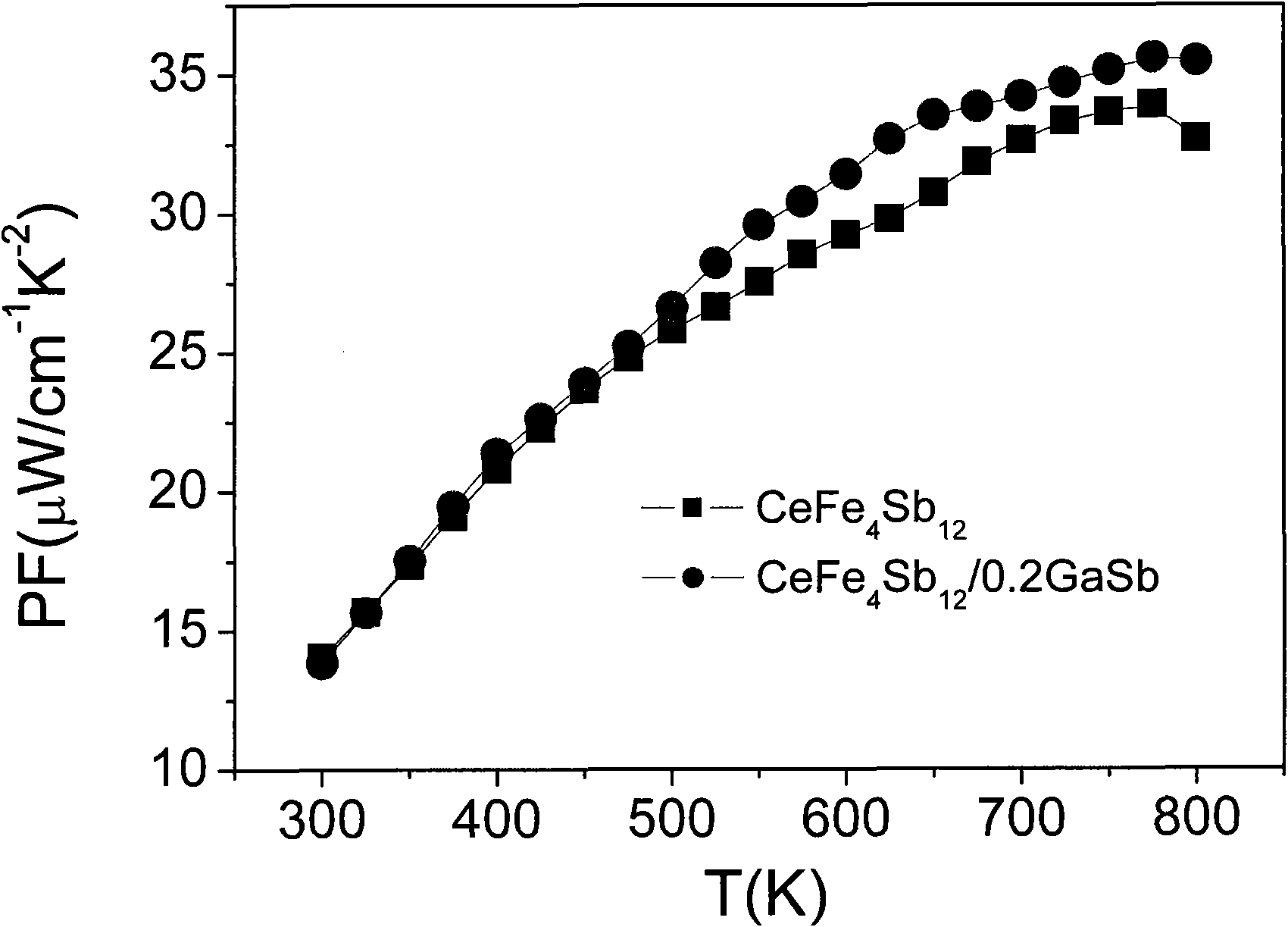

[0102] Example 1: CeFe 4 Sb 12 / 0.2GaSb composite material

[0103] The metal raw materials Ce, Fe, Sb, and Ga are mixed in the glove box according to the molar ratio of 1:4:12.2:0.2, and the raw materials are sealed in a quartz tube with a carbon film on the inner wall, and the vacuum is drawn while using argon plasma The flame is used for packaging, and the quartz tube is filled with a small amount of Ar gas for protection. The mixed raw materials were melted at 1000° C. for 12 hours. Quenching is carried out after melting, the quenching medium is brine, and the quenching speed is about 300°C / s. After quenching, the quartz tube was annealed at 700°C for 120 hours, and the obtained block was ground into fine powder and then subjected to spark plasma sintering. The sintering temperature was 600°C, the holding time was 5 minutes, and the pressure was 50MPa. The field emission SEM pictures show that the second phase (GaSb phase) is well distributed on or within the...

Embodiment 2

[0104] Example 2: Ce 0.45 Nd 0.45 Fe 3 CoSb 12 Material

[0105] The metal raw materials Ce, Nd, Fe, Co, and Sb are mixed in the glove box according to the molar ratio of 0.45:0.45:3:1:12, and the raw materials are sealed in the quartz tube with a carbon film evaporated on the inner wall, and the vacuum is drawn. It is packaged with an argon plasma flame, and a small amount of Ar gas is filled in the quartz tube for protection. The mixed raw materials were heated to 1100°C at a rate of 3°C per minute and melted for 12 hours. Quenching is carried out after melting, the quenching medium is brine, and the quenching speed is about 300°C / s. The quenched ingot and the quartz tube were annealed at 600°C for 200 hours. The block was ground into fine powder and then spark plasma sintered. The sintering temperature was 600°C, the holding time was 10 minutes, and the pressure was 60MPa. Tests showed that Ce 0.45 Nd 0.45 Fe 3 CoSb 12 Has a ratio of (single) fil...

Embodiment 3

[0106] Example 3: Ce y Fe x co 4-x Sb 12 / 0.1GaSb material

[0107] The metal raw materials Ce, Fe, Co, Sb, and Ga are mixed in the glove box according to the molar ratio of 0.6:0.4:3:1:12.1:0.1, and the raw materials are sealed in a quartz tube with a carbon film evaporated on the inner wall. The vacuum side is sealed with an argon plasma flame, and a small amount of Ar gas is filled in the quartz tube for protection. The mixed raw materials were heated to 1050°C at a speed of 1°C per minute and melted for 10 hours. Quenching is carried out after melting, and the quenching medium is brine. The quenched ingot was annealed at 650°C for 96 hours together with the quartz tube. The block was ground into fine powder and then spark plasma sintered. The sintering temperature was 550°C, the holding time was 20 minutes, and the pressure was 50MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com