Preparation method of SnSe-based oriented polycrystalline thermoelectric material

A thermoelectric material and orientation technology, applied in the manufacture/processing of thermoelectric devices, thermoelectric device node lead-out materials, etc., can solve the problems of unfavorable industrial production application, insignificant difference in ZT value, poor orientation, etc., and achieve mechanical The effect of good performance, simple preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, the chemical formula of the polycrystalline SnSe-based thermoelectric material is SnSe.

[0030] The preparation process of the polycrystalline SnSe-based thermoelectric material is as follows:

[0031] (1) taking Sn particles and Se particles as reaction raw materials according to the stoichiometric ratio of SnSe;

[0032] (2) The reaction raw materials weighed in the step (1) are packed into a clean and dry first reaction vessel, the first reaction vessel is evacuated to below 10 Pa, and then the opening of the first reaction vessel is sealed with an oxyacetylene flame;

[0033] (3) Place the sealed first reaction vessel in a swing furnace heated to 920°C, and smelt and swing for 30 minutes;

[0034] (4) After the smelting is completed, turn off the power supply of the swing furnace, take out the first reaction vessel, and cool it to room temperature in the air to obtain an ingot of SnSe-based thermoelectric material;

[0035] (5) Grinding the ob...

Embodiment 2

[0038] In this embodiment, the chemical formula of the polycrystalline SnSe-based thermoelectric material is SnSe.

[0039] The preparation process of the polycrystalline SnSe-based thermoelectric material is basically the same as the preparation process in Example 1, except that the following step (7) is performed after step (6):

[0040] (7) the block obtained in step (6) is placed in In the graphite mold, put it into a hot-press furnace to evacuate to below 10pa, perform a second hot-press under the conditions of a temperature of 470°C and a pressure of 60Mpa, and then demould.

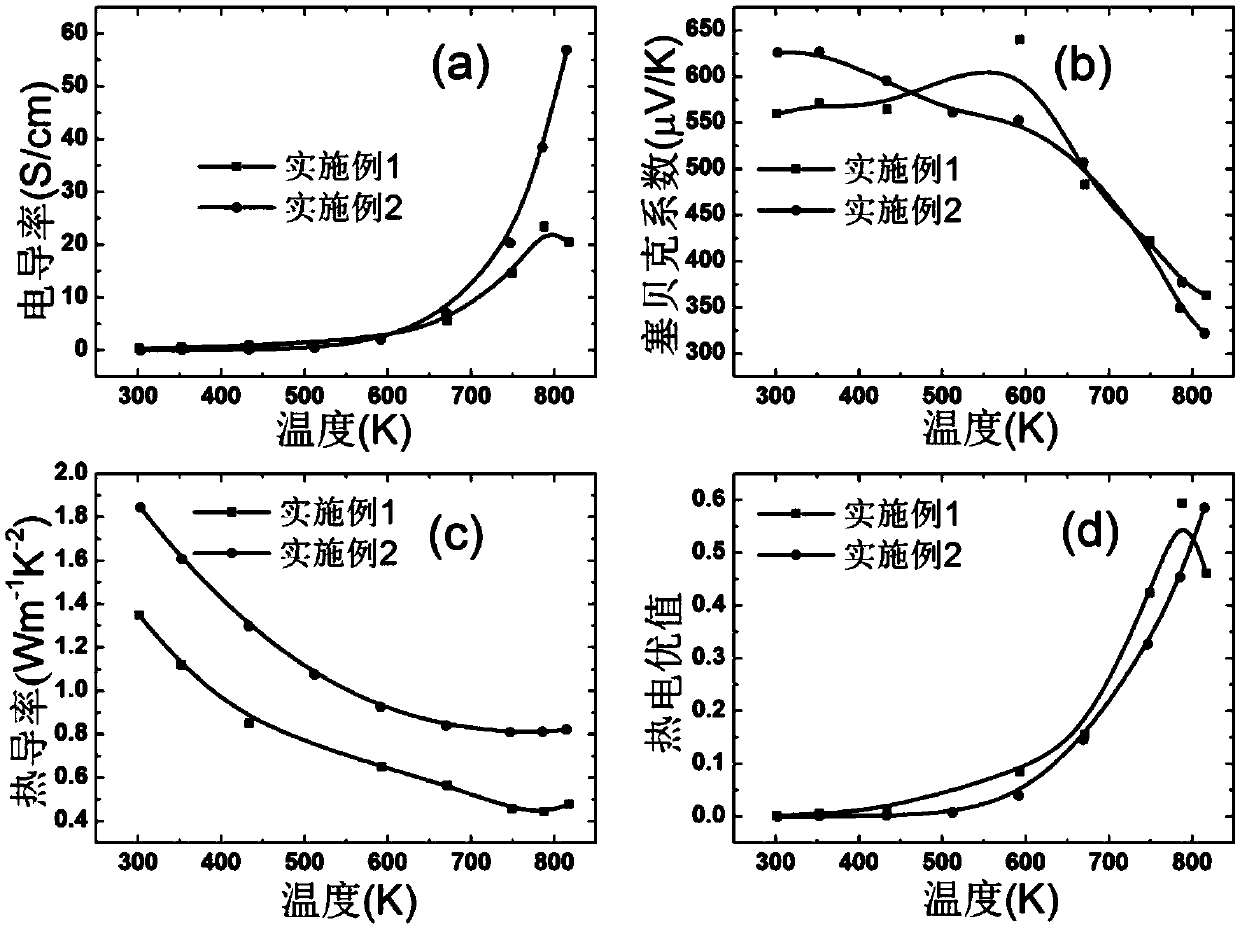

[0041] XRD (X-ray Diffraction, X-ray diffraction) tests and thermoelectric performance tests were performed on the bulk samples obtained in the above Examples 1 and 2 respectively, and the test directions were both perpendicular to the pressure direction.

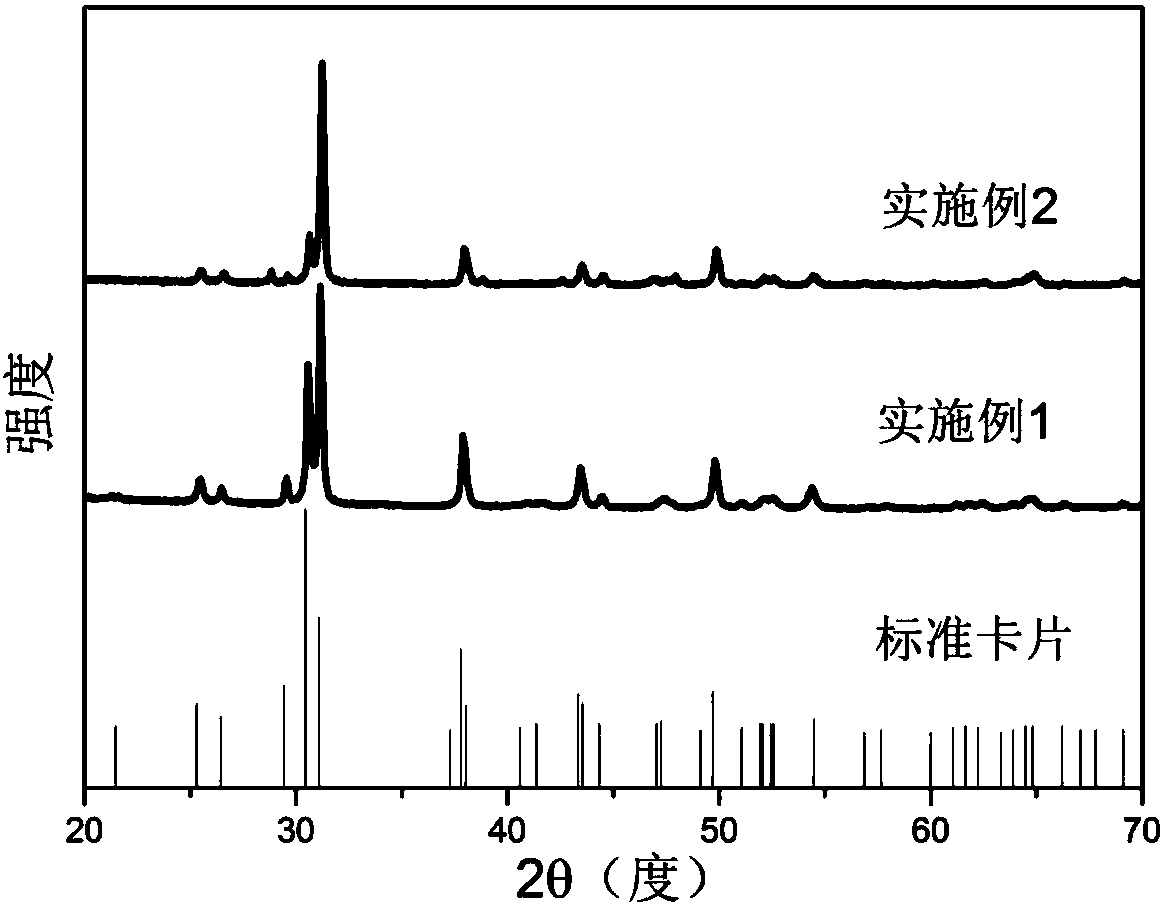

[0042] figure 1 It is the XRD spectrum of the bulk sample that above-mentioned embodiment 1 and 2 obtain, can know from it, the phase of the...

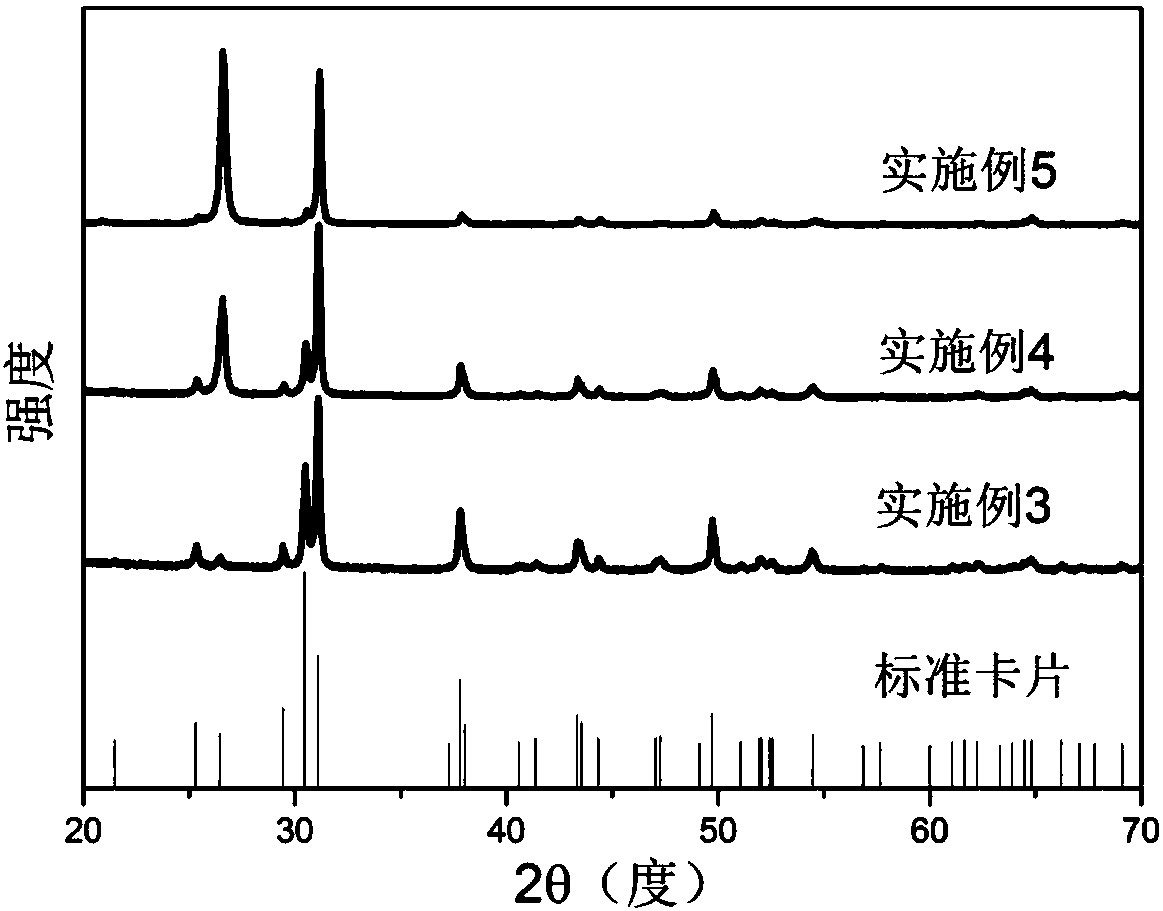

Embodiment 3

[0045] (1) According to Na 0.03 sn 0.97The stoichiometric ratio of Se takes Na particles, Sn particles and Se particles as reaction raw materials in the glove box;

[0046] (2) The reaction raw materials weighed in the step (1) are packed into a clean and dry first reaction vessel, the first reaction vessel is evacuated to below 10 Pa, and then the opening of the first reaction vessel is sealed with an oxyacetylene flame;

[0047] (3) Place the sealed first reaction vessel in a swing furnace heated to 920°C, and smelt and swing for 30 minutes;

[0048] (4) After the smelting is completed, turn off the power supply of the swing furnace, take out the first reaction vessel, and cool to room temperature in air to obtain Na 0.03 sn 0.97 Ingot casting of Se thermoelectric material;

[0049] (5) Utilize high-energy ball milling to obtain Na 0.03 sn 0.97 The Se thermoelectric material ingot is ground into powder, and the ball milling time is 15 minutes;

[0050] (6) Put the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com