Cu-Se-S system thermoelectric material and preparation method thereof

A thermoelectric material, cu-se-s technology, applied in the direction of thermoelectric device junction lead-out material, thermoelectric device manufacturing/processing, polycrystalline material growth, etc., can solve the problem of difficult to obtain alloy materials, and achieve thermoelectric performance improvement , the effect of improving the thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

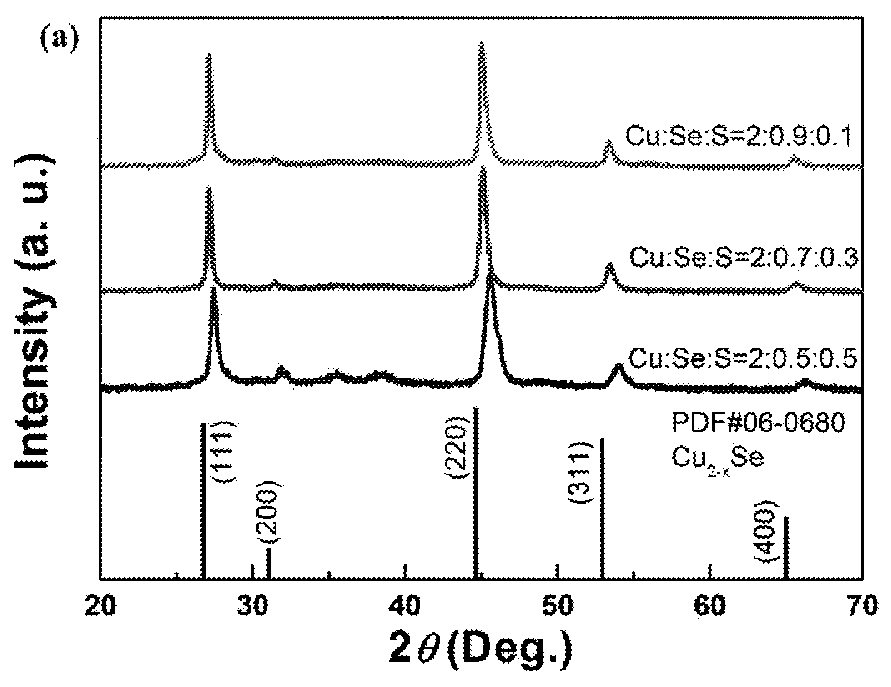

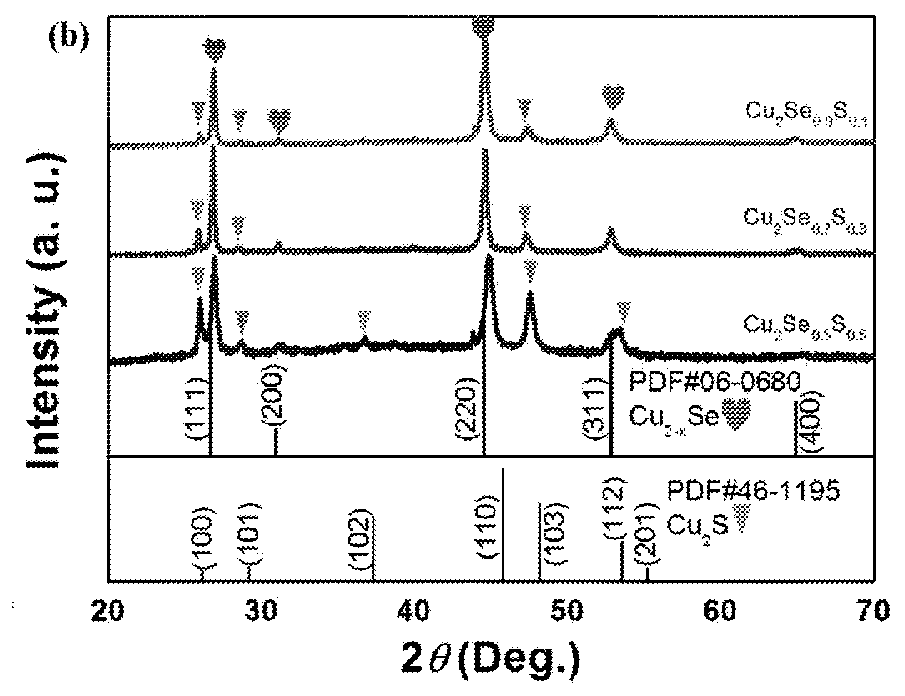

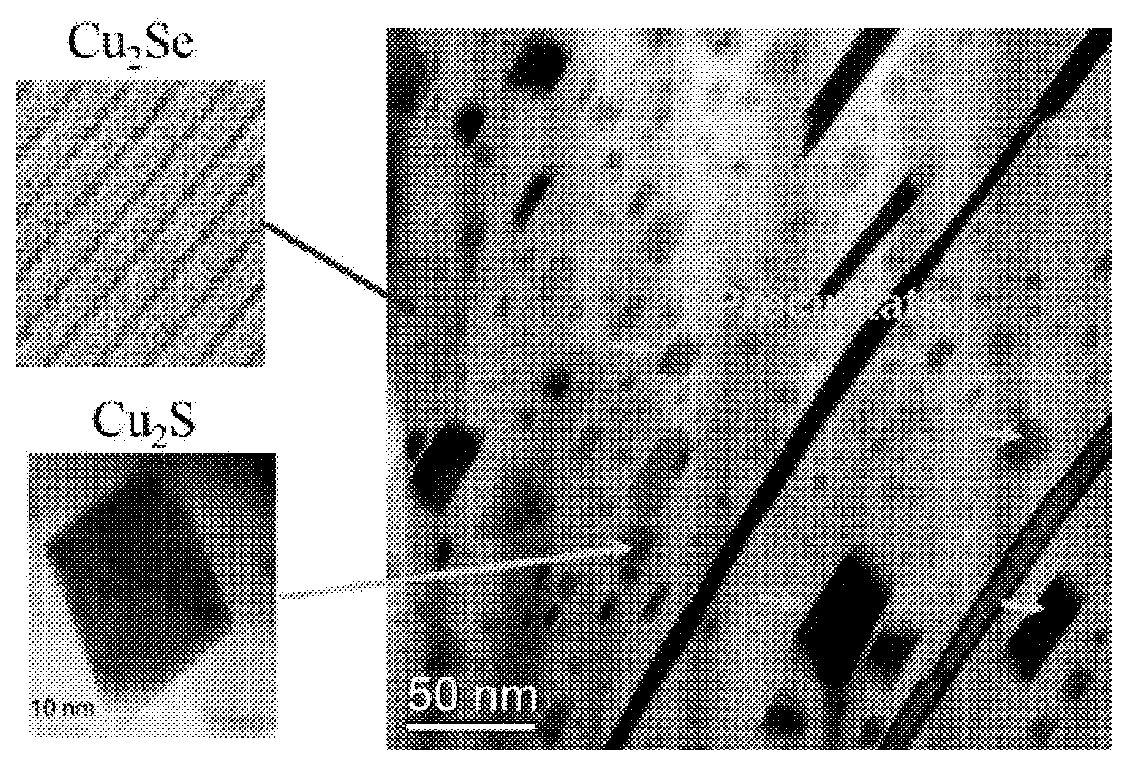

[0033] The preparation process of the above-mentioned Cu-Se-S system thermoelectric material includes the following steps:

[0034] (1) The prepared Cu:Se:S molar ratio is 2:(1-x):x sulfur powder, selenium powder and copper oxide powder are added in the ethylenediamine solvent, form mixed solution, sulfur powder, selenium The purity of powder and copper oxide powder is not less than 99.9%, after adding reducing agent and NaOH in the mixed solution, reducing agent is hydrazine hydrate (N 2 h 4 ·H 2 (0), so that the pH value of the mixed solution is 12 to 14, and the hydrothermal reaction is carried out at a temperature of 100 to 200 ° C. The time of the hydrothermal reaction is 6 to 12 hours, and the single-phase Cu-Se-S alloy powder and residual solution.

[0035] The reaction equation in the above hydrothermal reaction is:

[0036] 2CuO+2N 2 h 4 ·H 2 O→Cu 2 O+2NH 4 ++H 2 O+N 2 ↑ (1)

[0037] Se+2N 2 h 4 ·H 2 O→Se 2- +2NH 4 +N 2 +H 2 O↑ (2)

[0038] 2CuO+2N ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com