Flexible temperature-pressure sensor, and preparation method and application thereof

A pressure sensor and flexible technology, applied in the field of sensing materials, can solve problems such as the influence of temperature sensing reliability, achieve the effect of improving thermoelectric performance and avoiding mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

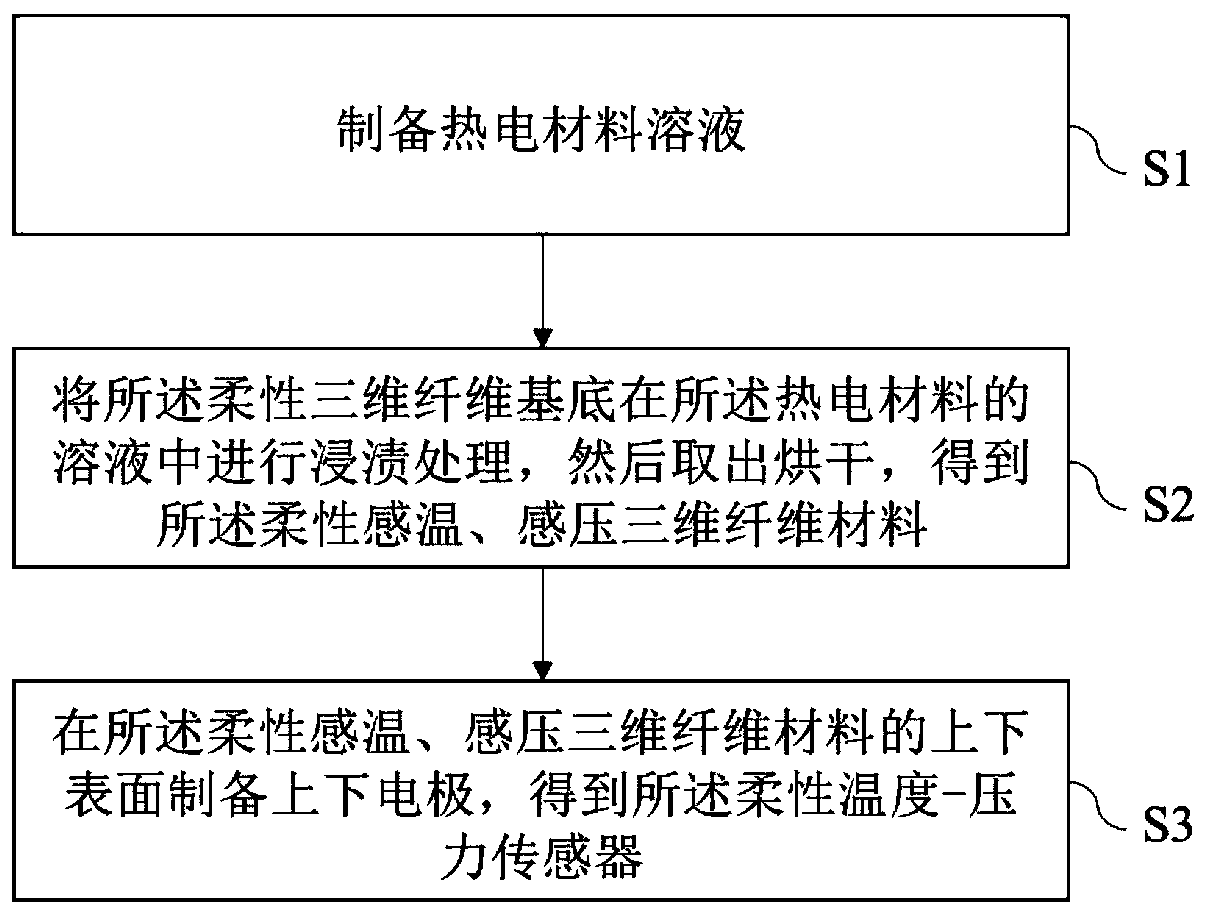

[0039] see figure 1 As shown, the preparation method of the flexible temperature-pressure sensor provided by the invention comprises the following steps:

[0040] S1. Prepare a thermoelectric material solution;

[0041] S2. Dip the flexible three-dimensional fiber substrate in the solution of the thermoelectric material, and then take it out and dry it to obtain the flexible temperature-sensitive and pressure-sensitive three-dimensional fiber material;

[0042] S3. Prepare upper and lower electrodes on the upper and lower surfaces of the flexible temperature-sensitive and pressure-sensitive three-dimensional fiber material to obtain the flexible temperature-pressure sensor.

[0043]Preferably, the flexible three-dimensional fiber substrate should have a certain degree of hydrophilicity, such as knitted fabrics prepared by compounding one or more fibers in cotton, polyester, nylon, polyurethane, polyamide, glass fiber, and carbon fiber, Woven, non-woven or three-dimensional f...

Embodiment 1

[0054] The flexible temperature-pressure sensor that embodiment 1 provides, its preparation method is as follows:

[0055] S1. Select PEDOT:PSS aqueous solution (specification: Clevios PH1000, concentration: 1.3wt%) as the thermoelectric material solution;

[0056] S2. Select a three-dimensional fabric with a size of 10mm×10mm×2mm as a flexible three-dimensional fiber substrate, and immerse it in the PEDOT:PSS aqueous solution described in step S1, accompanied by ultrasonic treatment for 2 hours, then take it out, and dry it at 130°C 15min;

[0057] Then immerse in the PEDOT:PSS aqueous solution prepared in step S1 again, accompanied by ultrasonic treatment for 30 minutes, and after taking it out, dry it at 130°C for 15 minutes;

[0058] S3. Brush silver paste on the upper and lower surfaces of the prepared flexible temperature-sensitive and pressure-sensitive three-dimensional fiber material as an electrode with a thickness of 40 μm, and dry it at 80° C. for 5 minutes to obt...

Embodiment 2

[0060] As an improvement, the flexible temperature-pressure sensor provided in embodiment 2 has a preparation method as follows:

[0061] S1. Add DMSO with an aqueous solution volume fraction of 5% to PEDOT:PSS aqueous solution (specification: Clevios PH1000, concentration: 1.3wt%), and then sonicate for 1 hour to obtain PEDOT:PSS mixed solution;

[0062] S2. Select a three-dimensional fabric with a size of 10mm × 10mm × 2mm, including an intermediate layer with a void structure, as a flexible three-dimensional fiber substrate, and immerse it in the PEDOT:PSS mixed solution prepared in step S1, accompanied by ultrasonic treatment for 2 hours, and then Take it out and dry it at 130°C for 15 minutes;

[0063] Then immerse in the PEDOT:PSS mixed solution prepared in step S1 again, accompanied by ultrasonic treatment for 30 minutes, and after taking it out, dry it at 130°C for 15 minutes;

[0064] Immediately immerse the sample in the EG solution after taking it out, soak it for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com