Preparation method of thin-film thermoelectric material

A thermoelectric material and thin film technology, which is applied in the field of preparation of thin film thermoelectric materials, can solve the problems of low energy utilization rate of thermoelectric devices, limited application of thermoelectric materials, and low thermoelectric figure of merit of materials, and achieves improved thermoelectric conversion efficiency and easy scale. The effect of production, easy price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

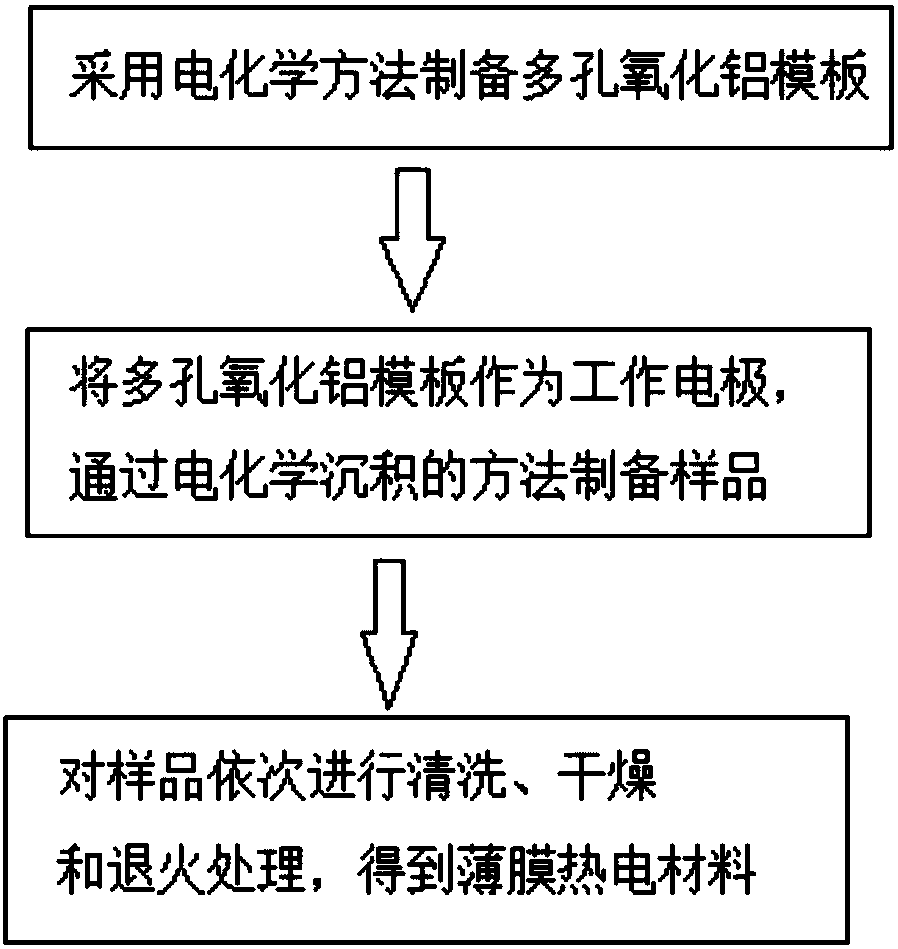

[0033] The invention discloses a preparation method of a thin-film thermoelectric material. The thin-film thermoelectric material is a low-dimensional Bi 2 Te 3 The preparation idea is to firstly prepare porous alumina (AAO) by electrochemical method, and then grow Bi on the surface and inside of the porous alumina by electrochemical deposition. 2 Te 3 Thin-film high-performance thermoelectric materials prepared from isobasic nanomaterials. The above-mentioned materials have performance characteristics such as low thermal conductivity, high Seebeck coefficient, and high electrical conductivity, which make them excellent in thermoelectric performance. The preparation of the material adopts a traditional electrochemical method which is easy for industrial production, has low requirements on the purity of raw materials, is cheap and easy to obtain and is suitable for large-scale production. The material's excellent thermoelectric performance and relatively low price provide te...

Embodiment 1

[0052] Embodiment 1: a kind of thin film thermoelectric material is nanoscale Bi 2 Te 3 , its preparation method is as follows:

[0053] (1) Choose an aluminum material with a purity of 99.99% as the substrate, sonicate it in ethanol for 5 minutes, remove the oil, place it in an oven at 500°C for annealing treatment for 2 hours, and take it out after cooling;

[0054] (2) Place it in 0.4M oxalic acid electrolyte, and prepare a porous anodized aluminum template with a pore size of 40-60nm through two anodic oxidations; see figure 2 with image 3 , figure 2 Scanning electron micrographs of the front side of the porous anodized aluminum oxide template (AAO) prepared for the electrochemical method, image 3 The scanning electron micrograph of the side of the porous anodized aluminum oxide template (AAO) prepared by electrochemical method, it can be found from the electron microscope photo that the porous anodic aluminum oxide template (AAO) of this embodiment has a pore size...

Embodiment 2

[0058] Embodiment 2: a kind of thin film thermoelectric material is nanoscale Sb 2 Te 3 , its preparation method is as follows:

[0059] (1) Choose an aluminum material with a purity of 99.99% as the substrate, sonicate it in ethanol for 5 minutes, remove the oil, place it in an oven at 500°C for annealing treatment for 2 hours, and take it out after cooling;

[0060] (2) Place in 0.4M oxalic acid electrolyte, and prepare a porous anodized aluminum template with a pore size of 10-30nm through two anodic oxidations;

[0061] (3) The porous anodized alumina template prepared in step (2) is the negative electrode, the platinum electrode network is the anode, and the tellurium dioxide and antimony trioxide acidified with nitric acid are the electrolyte and a small amount of complexing agent and additives are added. After electroplating for 5 hours, a sample is obtained; the complexing agent is tartaric acid, sodium tartrate or sodium periodate, and the additive is diaminocarbami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com