Preparation method of P-type bismuth telluride-based bulk thermoelectric material (Bi1-xSbx)2Te3

A thermoelectric material, bismuth telluride technology, is applied in the field of preparation of P-type bismuth telluride-based bulk thermoelectric material 2Te3, which can solve the problems of difficult processing and use of materials, volatile low-melting elements, and hindering the application space of materials, etc. Low production cost, high thermoelectric figure of merit, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a P-type bismuth telluride-based bulk thermoelectric material (Bi 1-x Sb x ) 2 Te 3 The preparation method, it comprises the steps:

[0026] (1) The elemental raw materials Bi, Sb, and Te powder are pressed by (Bi 1-x Sb x ) 2 Te 3 , 0.05≤x≤0.2, the chemical formula content is weighed and loaded into a quartz tube;

[0027] (2) Use homogenization equipment to homogenize the raw materials in the quartz tube for 2 hours, then vacuumize and seal the tube, and then fix it on the vertical lifting frame of the vertical solidification furnace;

[0028] (3) Preheat the vertical solidification furnace. The preheating temperature is 250-300°C, and the preheating and holding time is 30 minutes. Heating zone, the heating temperature of the heating zone is 500-560°C, when all the materials in the quartz tube pass through the heating zone, the quartz tube stops falling, and the heating zone stops heating after holding for a certain period of time; the h...

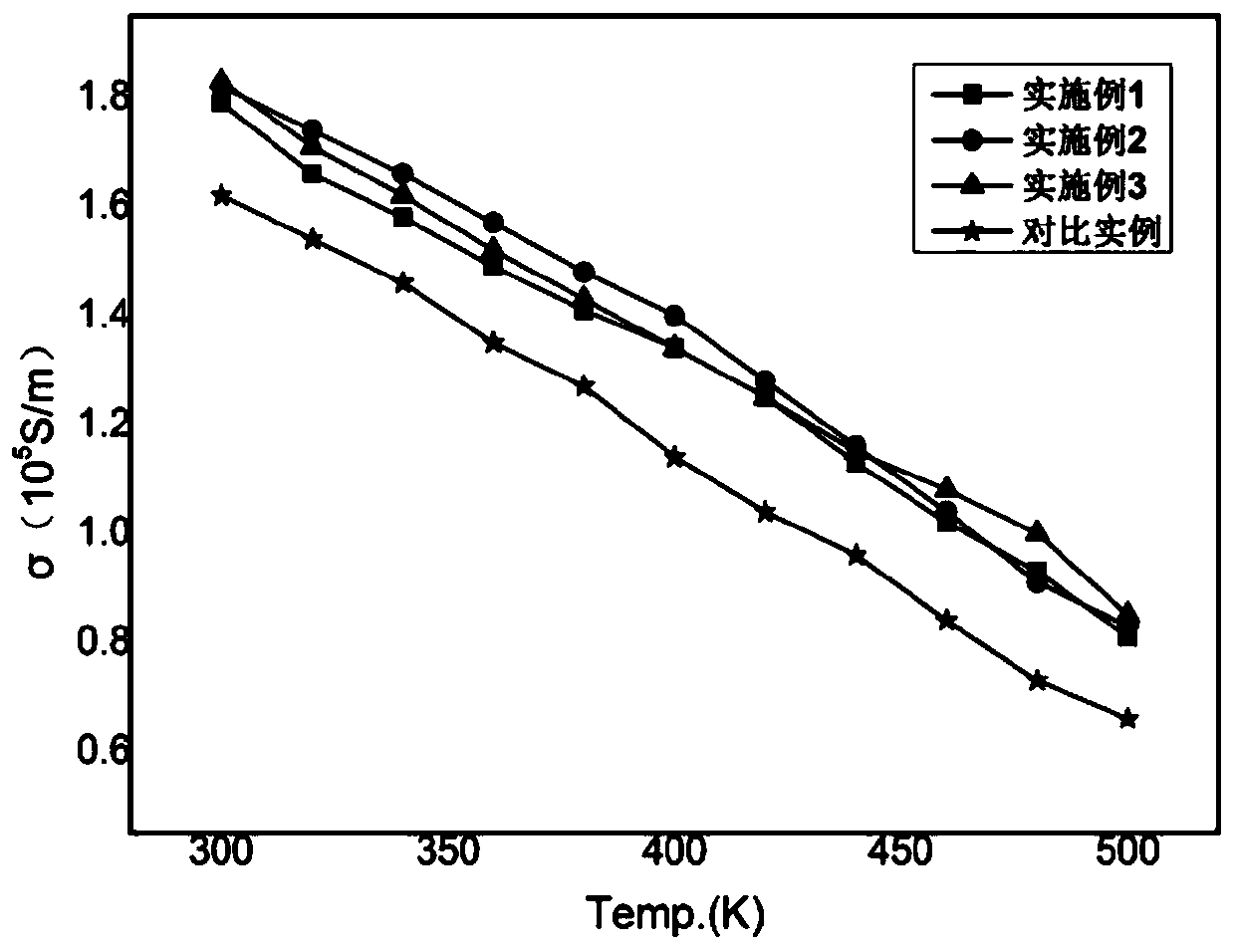

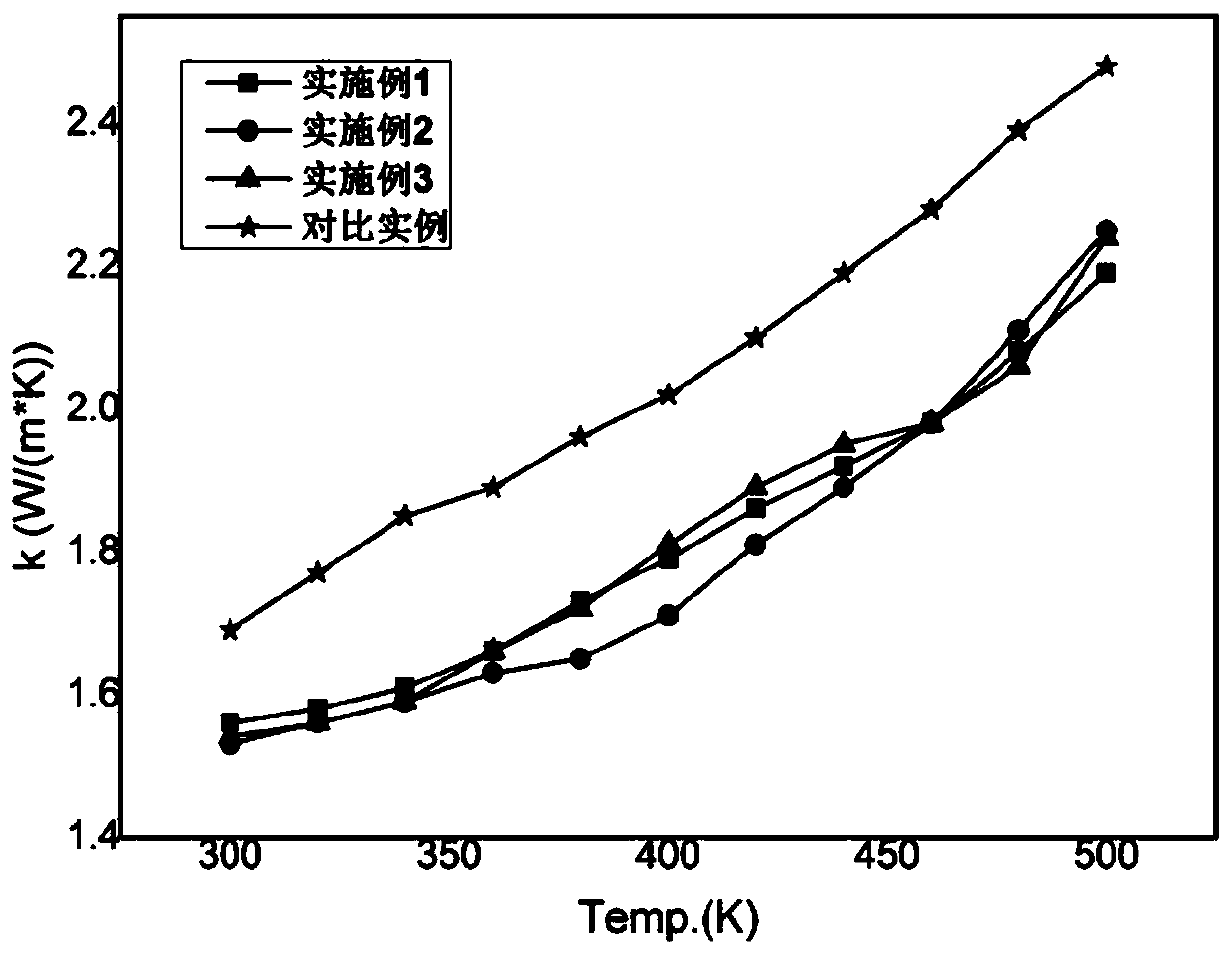

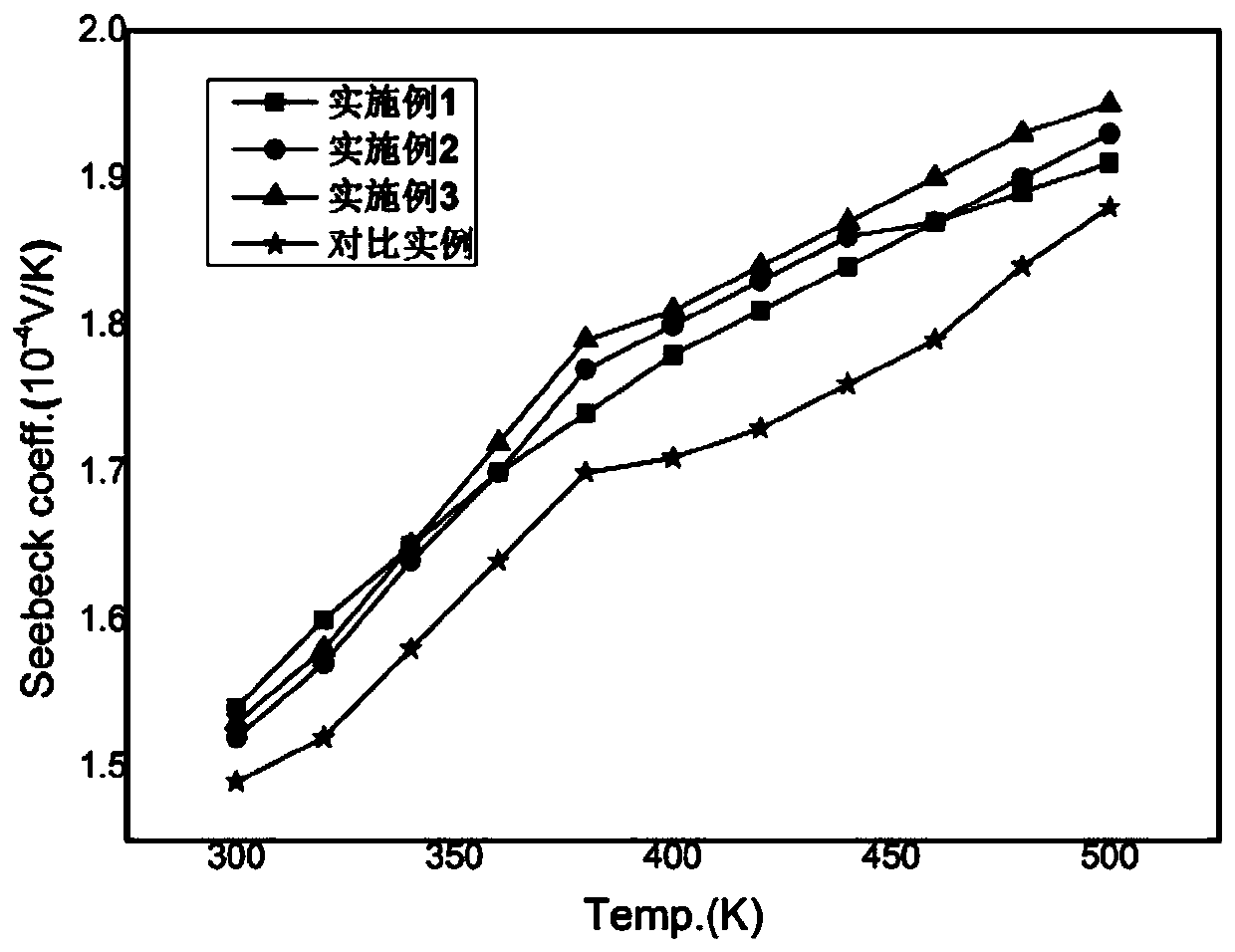

Embodiment 1

[0039] A P-type bismuth telluride-based bulk thermoelectric material (Bi 1-x Sb x ) 2 Te 3 The preparation method, it comprises the steps:

[0040] (1) Press (Bi 1-x Sb x ) 2 Te 3 , 0.05≤x≤0.2, chemical formula content Weigh 500g of elemental raw materials Bi, Sb, Te powder into a φ60×600mm quartz tube;

[0041] (2) Use homogenization equipment to homogenize the raw materials in the quartz tube for 2 hours, then vacuumize and seal the tube, and then fix it on the vertical lifting frame of the vertical solidification furnace;

[0042] (3) Preheat the vertical solidification furnace. The preheating temperature is 280°C, and the preheating holding time is 30 minutes. After preheating, the quartz tube falls vertically with the vertical lifting frame at a rate of 2cm / h and enters the heating zone of the vertical solidification furnace. , the heating temperature in the heating zone is 540°C. When all the materials in the quartz tube pass through the heating zone, the quartz tu...

Embodiment 2

[0045] A P-type bismuth telluride-based bulk thermoelectric material (Bi 1-x Sb x ) 2 Te 3 The preparation method, it comprises the steps:

[0046] (1) Press (Bi 1-x Sb x ) 2 Te 3 , 0.05≤x≤0.2, chemical formula content Weigh 300g of single raw material Bi, Sb, Te powder and put it into a φ60×600mm quartz tube;

[0047] (2) Use homogenization equipment to homogenize the raw materials in the quartz tube for 2 hours, then vacuumize and seal the tube, and then fix it on the vertical lifting frame of the vertical solidification furnace;

[0048] (3) Preheat the vertical solidification furnace. The preheating temperature is 250°C, and the preheating holding time is 30 minutes. After preheating, the quartz tube falls vertically with the vertical lifting frame at a rate of 2cm / h and enters the heating zone of the vertical solidification furnace. , the heating temperature in the heating zone is 500°C. When all the materials in the quartz tube pass through the heating zone, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com