Method for preparing misfit chalcogenide thermoelectric material by solid-phase reaction method

A solid-phase reaction method and chalcogenide technology, which is applied in the field of materials to achieve the effects of strong controllability, low thermal conductivity and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

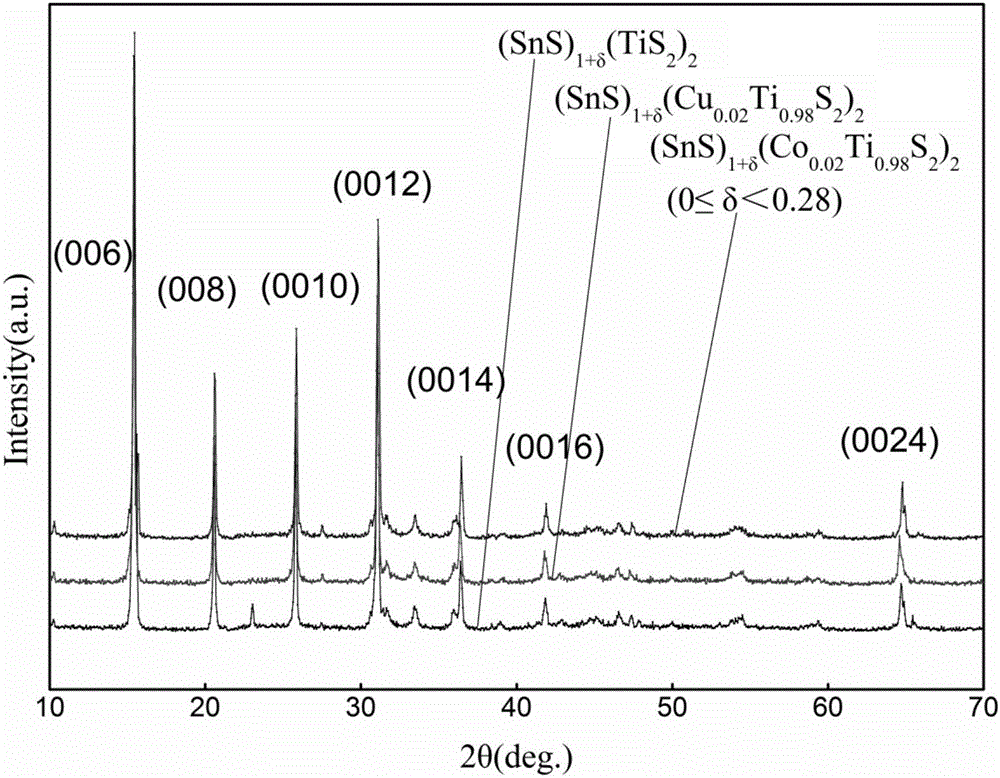

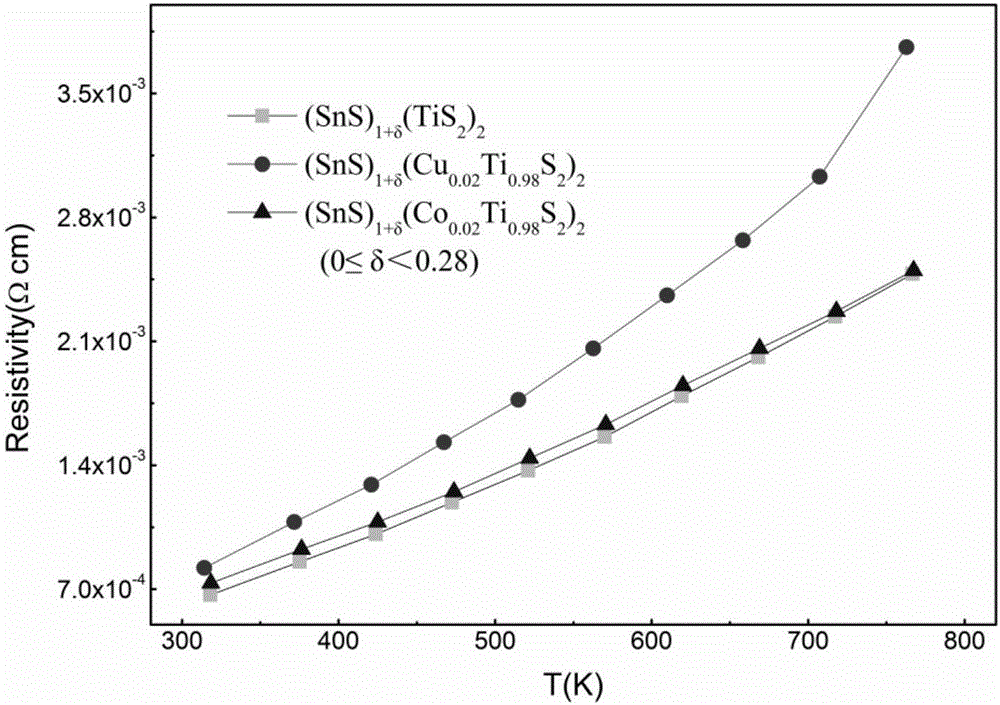

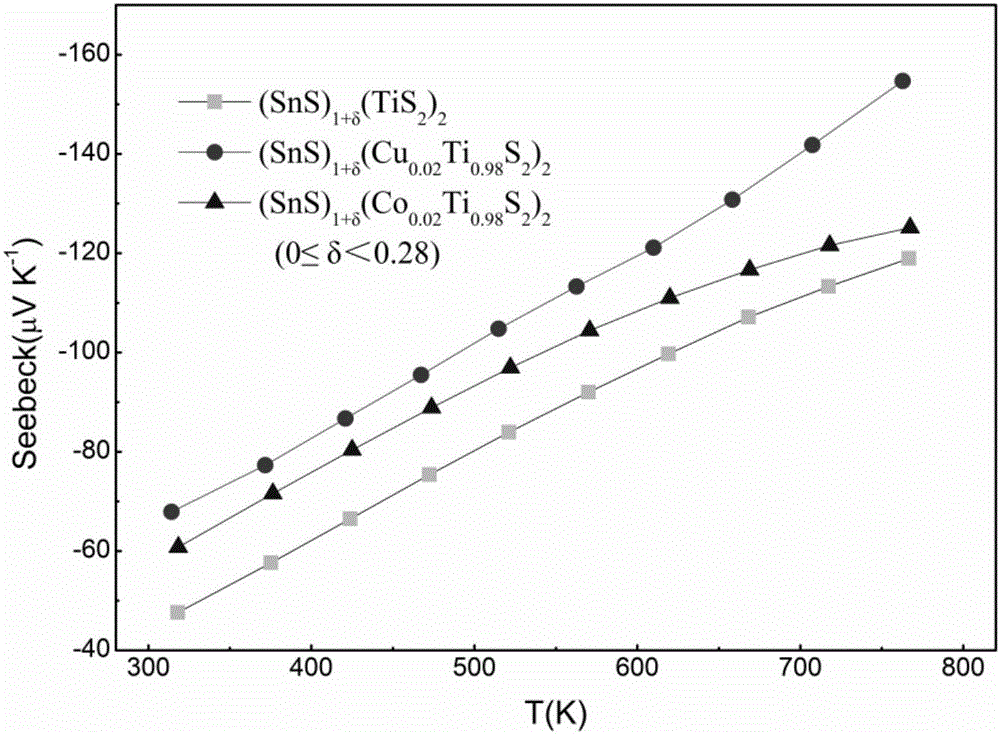

Image

Examples

Embodiment 1

[0032] (1) Weigh 2g of Sn powder, Cu powder or Co powder, Ti powder, and S powder according to the ratio of mass ratio 1:0.04:1.96:5, wherein the ratio of Cu powder or Co powder is 0.04, and the ratio of Ti powder It is 1.96, and then directly mix it in an agate mortar and grind for 30 minutes to make the powder mix evenly.

[0033] (2) Transfer the ground powder into a steel mold with Φ=10 mm, and press it with a pressure of 5 MPa for 5 min.

[0034] (3) Move the pressed sheet sample into a cleaned Φ=20mm quartz tube. Use a hydrogen-oxygen generator to seal the tube; then use a mechanical pump to pre-vacuumize, and then use a molecular pump to evacuate to 1.5×10 -3 Pa, seal the tube.

[0035] (4) Finally, the quartz tube containing the sample is placed in a box furnace for sintering.

[0036] (5) The temperature rise for the first sintering: After 1000 minutes, the temperature was raised from room temperature to 500°C, and kept for 720 minutes; after 300 minutes, the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com