Antimony-doped high-performance GeTe-PbTe solid solution thermoelectric material and preparation method thereof

A thermoelectric material and high-performance technology, applied in the direction of thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, etc., can solve the problems of limited solid solubility of materials and achieve high thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

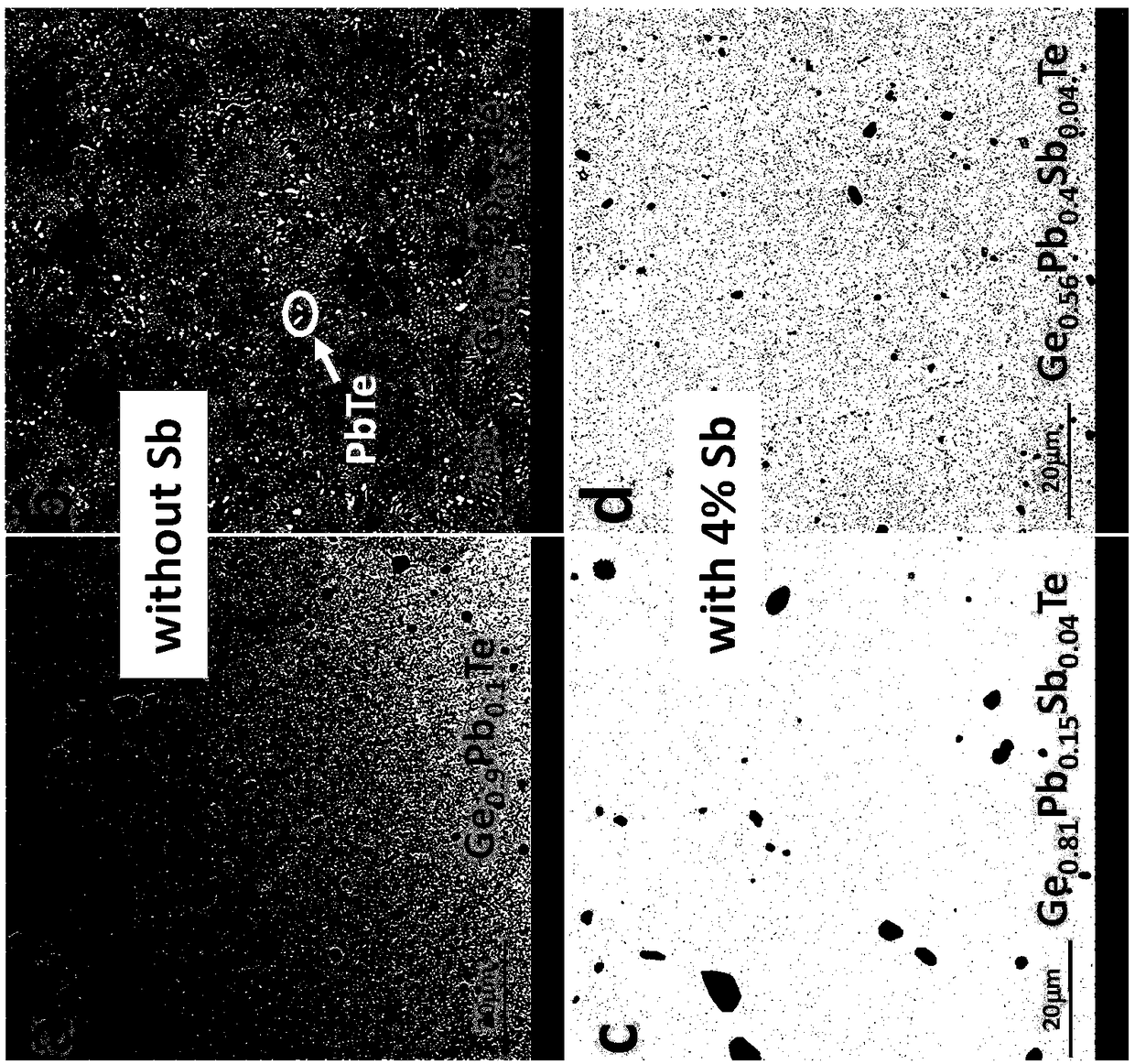

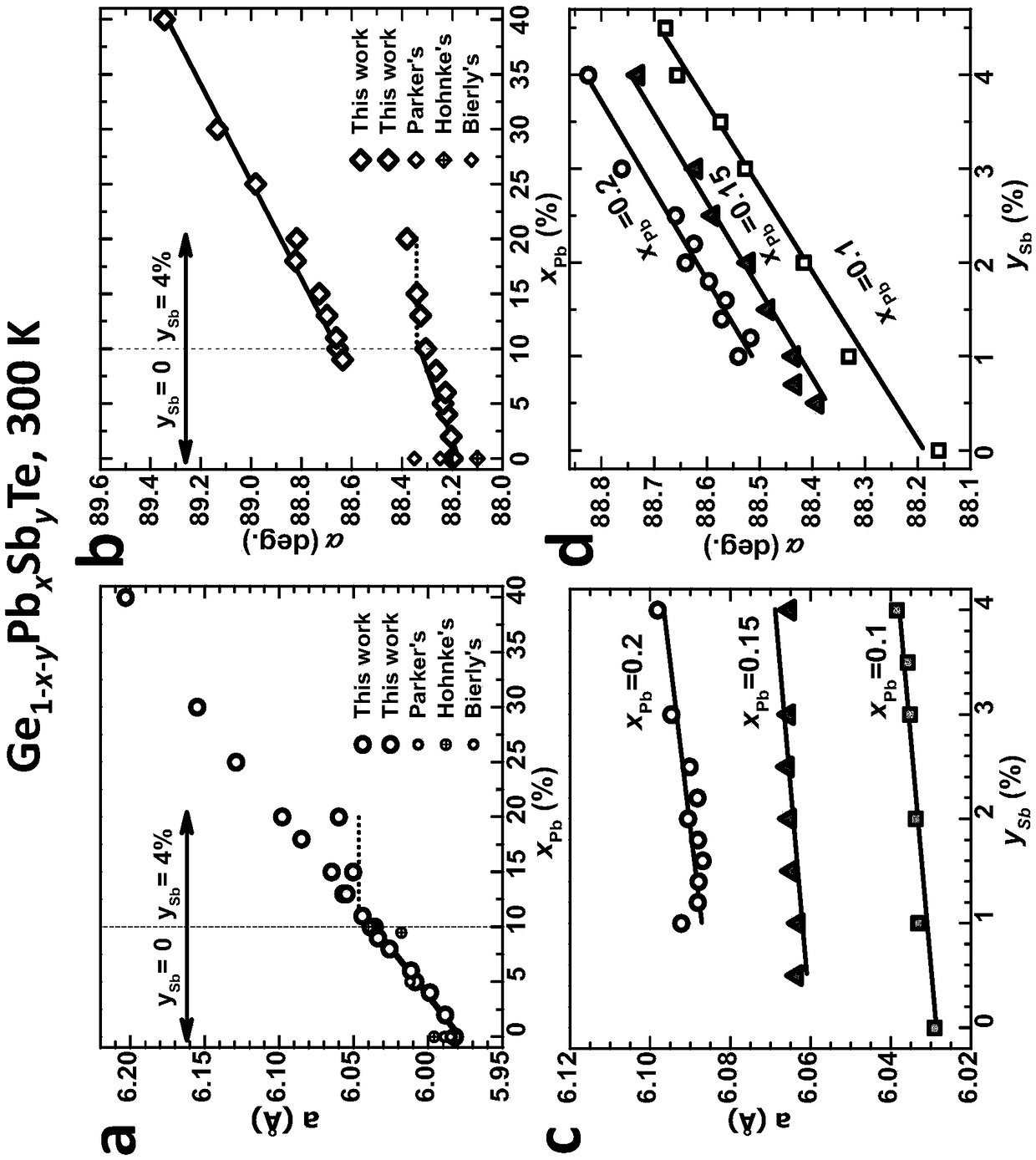

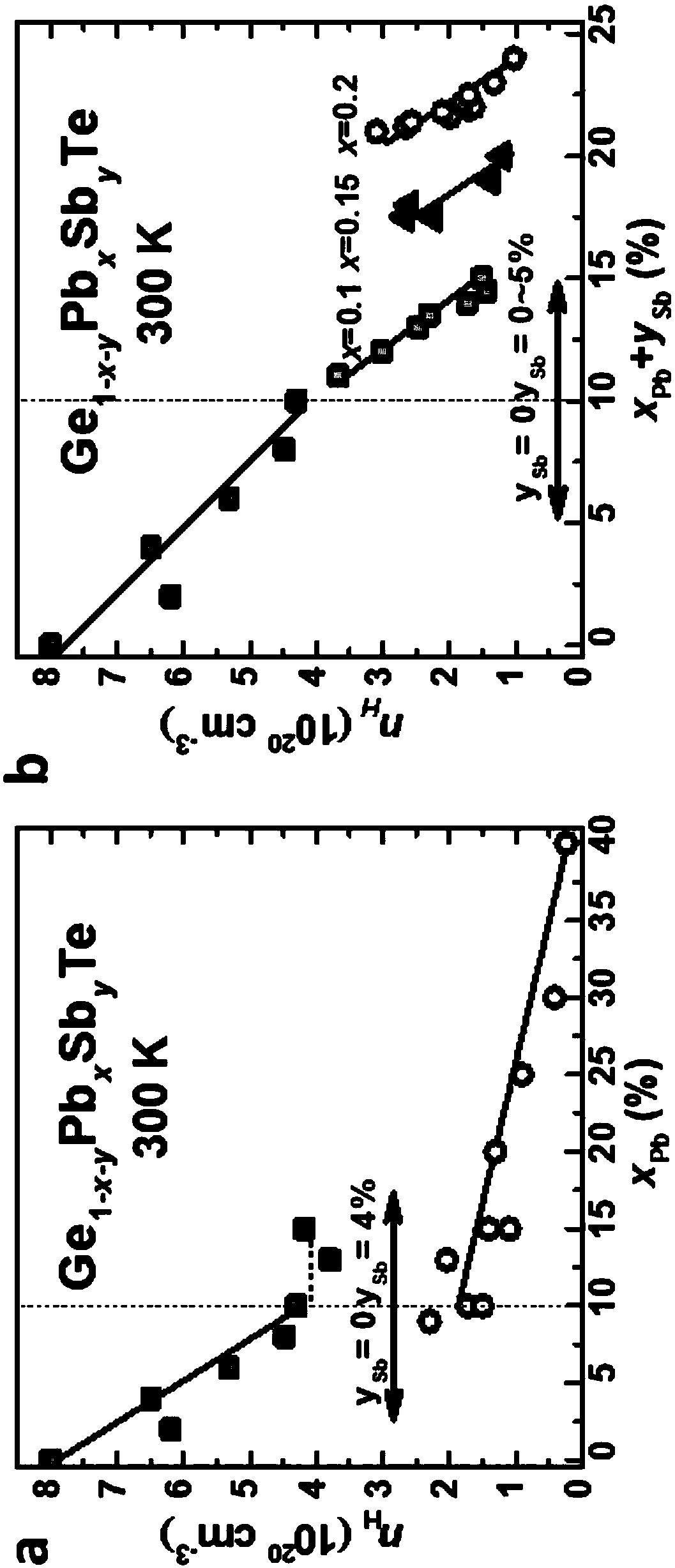

[0042] A kind of GeTe-PbTe solid solution thermoelectric semiconductor material, its chemical formula is Ge 1-x-y Pb x Sb y Te, x=0.1-0.2, y=0-0.07. Get x=0.1,0.15,0.2 in the present embodiment (when x=0.1, chemical formula is Ge 0.9-y Pb 0.1 Sb y Te, when x=0.15, the chemical formula is Ge 0.85-y Pb 0.15 Sb y Te, when x=0.2, the chemical formula is Ge 0.8-y Pb 0.2 Sb y Te, that is, the range of PbTe is adjustable, and Sb doping is used to control the carrier concentration and optimize the thermoelectric performance under different components).

[0043] Different components of Ge can be obtained according to the following preparation methods 1-x-y Pb x Sb y Te bulk material:

[0044] (1) According to different values of x and y, the chemical formula is Ge 1-x-y Pb x Sb y The stoichiometric ratio of Te (x=0.1~0.2, y=0~0.07) Weigh the elemental raw materials germanium Ge, antimony Sb, lead Pb and tellurium Te with a purity greater than 99.99%, place the raw ma...

Embodiment 2

[0054] Different from Embodiment 1, the value of x in this embodiment is 0.25.

Embodiment 3

[0056] The difference from Example 1 is that in the step (2) of this example, the temperature is slowly raised to 950° C. at a rate of 150° C. per hour, and kept at a temperature of 10 hours, followed by rapid quenching and cooling to obtain the first ingot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com